Inside the real-world performance of synthetic filter media for modern HVAC

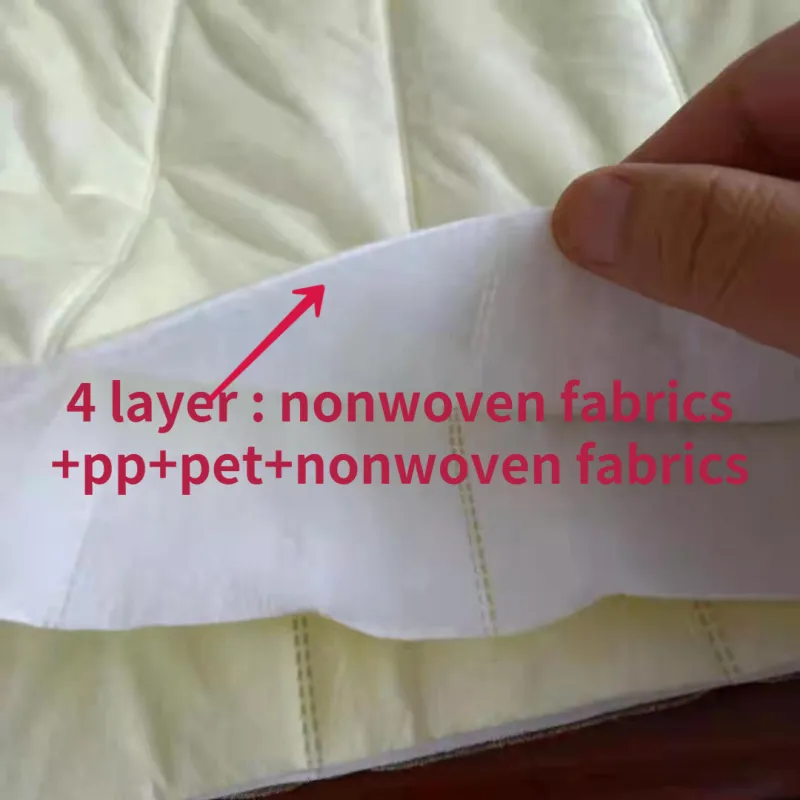

I’ve spent enough time in air-handling rooms to know what matters: low resistance, stable capture, and supply chain that doesn’t go missing the week your plant ramps up. The Synthetic Pocket Filter Media from Handan, Hebei (Second Buliding and Studying No21 shiji street, Handan, Hebei China) hits those practical notes, and—surprisingly—it’s not trying to be fancy for the sake of it. Just laminated composites, melt-blown polypropylene, and crisp ultrasonic seams that hold up.

What’s trending (and why you should care)

Since ISO 16890 became the reference, specifiers have been shifting from the old F-classes toward ePM1/ePM2.5 language. Energy costs pushed low-ΔP designs to the front. Fiberglass shedding concerns? That’s why synthetic filter media keeps eating market share—no loose fibers, better humidity resilience, and consistent pleat/pocket shaping.

Product snapshot: Synthetic Pocket Filter Media

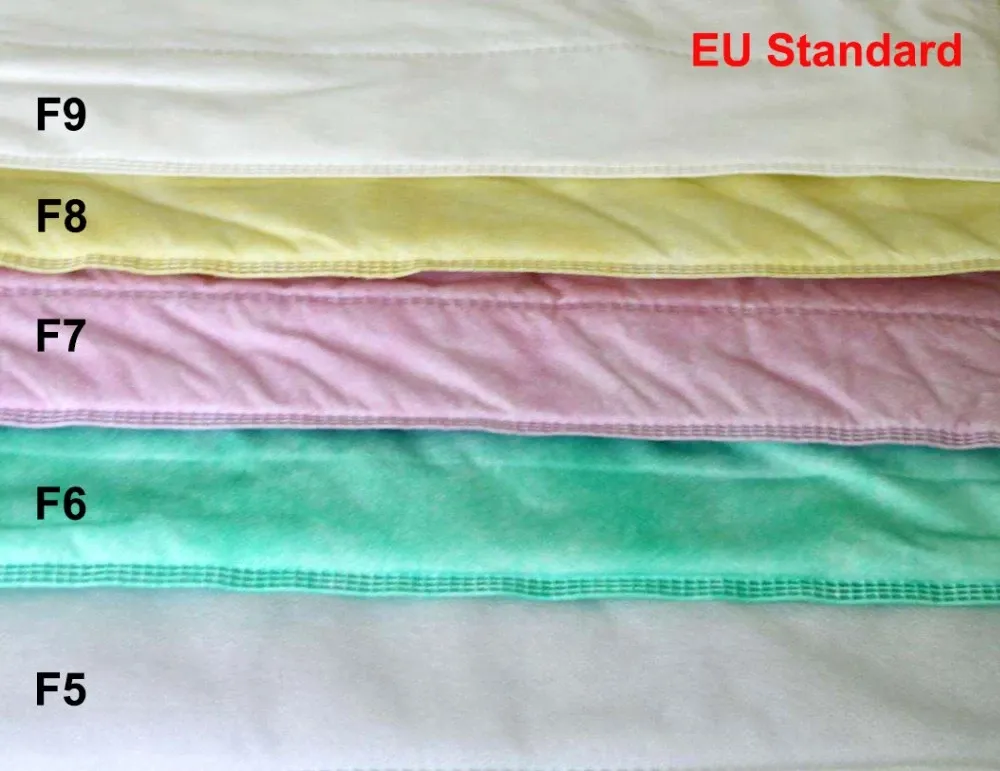

Technical stack is straightforward: laminated composites with a melt-blown core, ultrasonically stitched lanes for rigid pockets. Efficiency tags read F5–F9 (≈ ISO ePM10 70 to ePM1 80 in typical mappings), aimed at bag filters and panel prefilters. Many customers say the real perk is the pressure stability after dust loading.

| Parameter | Spec (typical) |

|---|---|

| Material | Polypropylene (PP) laminated composite, melt-blown core |

| Efficiency | F5–F9; ≈ ePM10 60–90, ePM2.5 50–75, ePM1 up to ≈80 (real-world may vary) |

| Basis weight | ≈120–260 g/m² |

| Initial ΔP @ 0.944 m/s | F7 ≈ 90–120 Pa |

| Final ΔP | ≤ 450 Pa (per common HVAC practice) |

| Temperature limit | ≤ 70 °C; 100% RH non-condensing |

| Roll width / length | Standard 600–750 mm; custom on request |

How it’s made (quick process flow)

PP resin → melt-blown microfibers (possible electrostatic charge) → spunbond backing → multi-layer lamination → ultrasonic sewing for pocket lanes → QC and ISO 16890/ASHRAE 52.2 bench tests → roll slitting and packing. Service life: often 9–12 months in offices; 3–6 months in heavy dust; always replace by ΔP, not calendar.

Applications and advantages

– Commercial HVAC, hospitals, data centers, pharma & food plants, automotive paint shops.

– Advantages: low resistance, high capture stability, no glass fiber shedding, clean ultrasonics for robust pockets, easy MERV 11–14 targets with synthetic filter media stacks.

Vendor snapshot (informal, but useful)

| Vendor | Media type | Efficiency | F7 ΔP (typ.) | MOQ | Customization |

|---|---|---|---|---|---|

| FiltersMaterial (Hebei) | synthetic filter media, laminated | F5–F9 | ≈ 90–120 Pa | Low | Widths, GSM, stitching |

| Global Brand A | synthetic filter media, charged | ePM1–ePM10 | ≈ 100–130 Pa | Medium | Color coding, FR |

| Regional Maker B | PP/spunbond composite | F6–F8 | ≈ 110–150 Pa | High | Limited |

Data indicative; always confirm on a certified test rig.

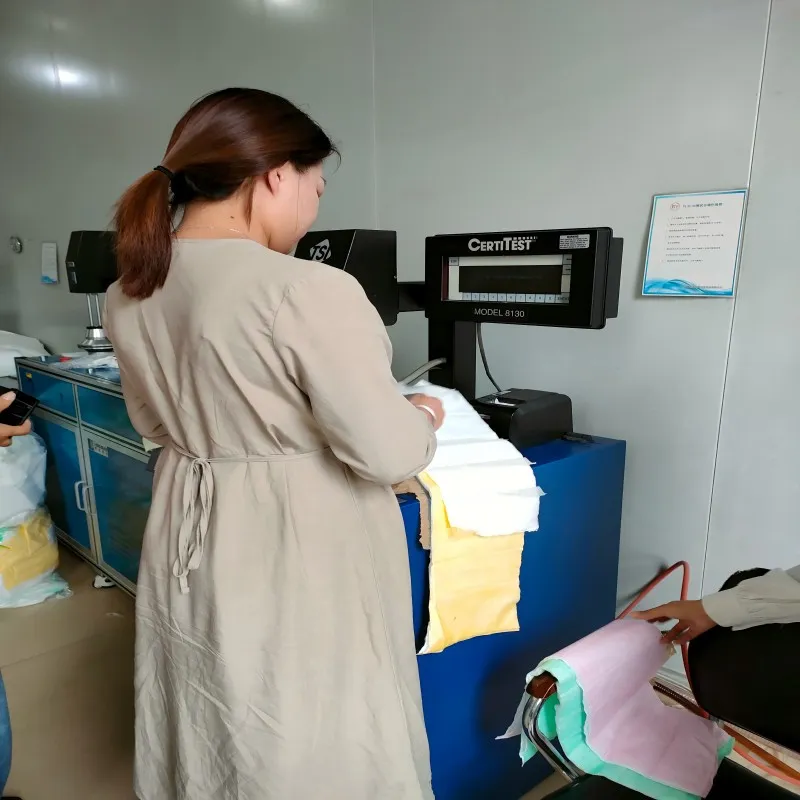

Customization, testing, and certifications

Options: basis weight, pocket lane pitch, color ID, antistatic, FR grades on request. Testing against ISO 16890 and ASHRAE 52.2; HEPA-adjacent checks use ISO 29463/EN 1822 (when needed). Factory runs ISO 9001 QA; PP media typically RoHS/REACH-friendly. Typical F7 lab note: ePM1 ≈ 55–65%, dust holding capacity ≈ 200–300 g/m².

Field notes (mini case studies)

– Automotive paint line: switched to synthetic filter media F7 bags, cut average ΔP by ~12% and extended changeout from 10 to 14 weeks.

– City hospital AHU: F8 pockets upstream of terminal filters; particle counts in wards improved ~25% for 0.3–1 μm band, according to the facility’s quarterly IAQ report.

Practical tips

– Size filters for 1.5–2.5 m/s face velocity to keep ΔP honest.

– Replace by pressure (not by the calendar).

– Store rolls dry; avoid compressing pockets before installation. To be honest, half the “media problems” I hear are actually handling issues.

Bottom line

If you’re after consistent F5–F9 performance with low resistance and simple deployment, this synthetic filter media is a tidy, scalable choice. Not flashy—just solid science and careful manufacturing.

Authoritative citations

- ISO 16890: Air filters for general ventilation (2016–2022 editions).

- ASHRAE Standard 52.2: Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size.

- ISO 29463 / EN 1822: High-efficiency air filters and filter media for removing particles in air.

- EN 779 (historical): Particulate air filters for general ventilation—replaced by ISO 16890.

- Eurovent 4/23: Energy efficiency evaluation of air filters for general ventilation.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog