The Critical Role of Advanced Filtration in Modern Finishing Operations

In industrial painting and finishing applications, particularly within automotive, aerospace, and general manufacturing sectors, maintaining an immaculate paint environment is paramount. The quality of the final finish is directly dependent on the purity of the air inside the spray booth. Contaminants such as dust, lint, and airborne particulates can lead to defects, requiring costly rework and impacting production schedules. This is where high-performance spray booth ceiling filters play an indispensable role, acting as the primary barrier against airborne impurities entering the critical painting zone.

These specialized filters are engineered to deliver a uniform, low-turbulence airflow throughout the spray booth, creating a clean room-like environment essential for achieving flawless finishes. Their design and material composition are critical for capturing even the finest particles, ensuring optimal air quality and protecting sensitive equipment and products from contamination.

Manufacturing Process: Precision Engineering for Superior Air Quality

The production of high-performance spray booth ceiling filters is a meticulous process, integrating advanced material science with precision manufacturing techniques to ensure optimal filtration efficiency and longevity. The goal is to create a filter medium that captures microscopic contaminants while allowing high airflow with minimal pressure drop.

Key Steps in the Manufacturing Process:

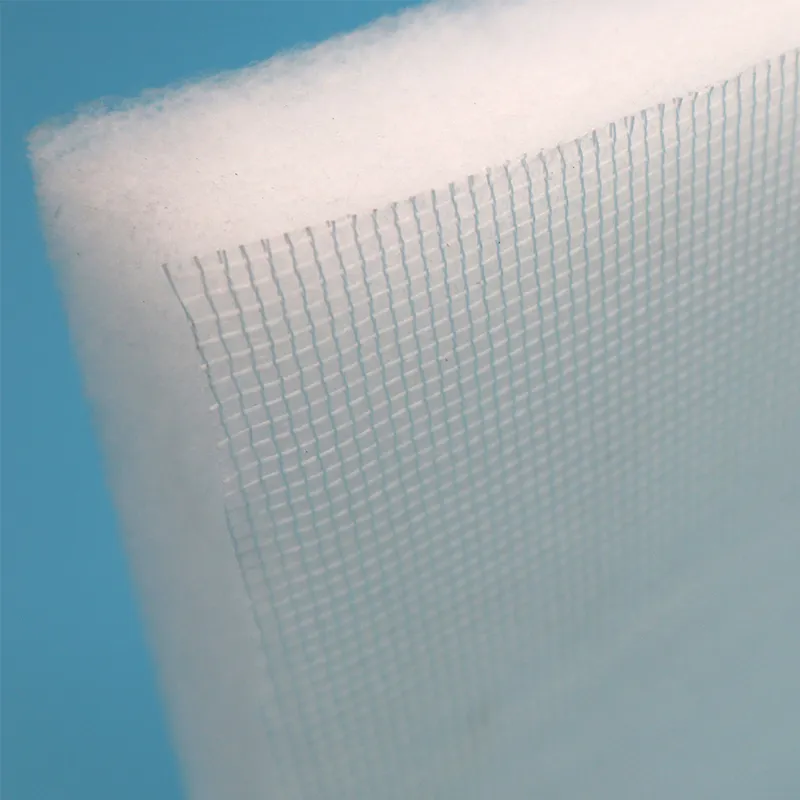

- Material Selection and Preparation: High-grade synthetic fibers, typically polyester or polypropylene, are chosen for their consistent diameter, durability, and electrostatic properties. These raw fibers undergo carding and cross-lapping to create a uniform, multi-layered mat with progressively finer densities. This gradient density structure is crucial for capturing particles of varying sizes efficiently without premature clogging.

- Thermal Bonding and Impregnation: The fiber mats are then thermally bonded to enhance structural integrity and prevent fiber shedding. Following this, a significant number of filters are impregnated with a specialized, non-migratory tackifier. This adhesive coating effectively captures and retains fine dust particles, preventing their re-release into the airstream. The tackifier’s formulation is critical to ensure it does not bleed or contaminate the painted surfaces.

- Scrim Backing Application: For enhanced stability and to prevent tearing during installation and operation, a non-woven scrim backing (often a thin polyester mesh) is applied to the clean air side of the filter media. This scrim also helps maintain the filter’s shape under airflow pressure.

- Pleating and Forming (for certain designs): While many ceiling filters are roll media, some advanced designs incorporate pleating or pocket formations to increase the surface area, thus extending service life and enhancing dust holding capacity. This involves precise folding or shaping of the media.

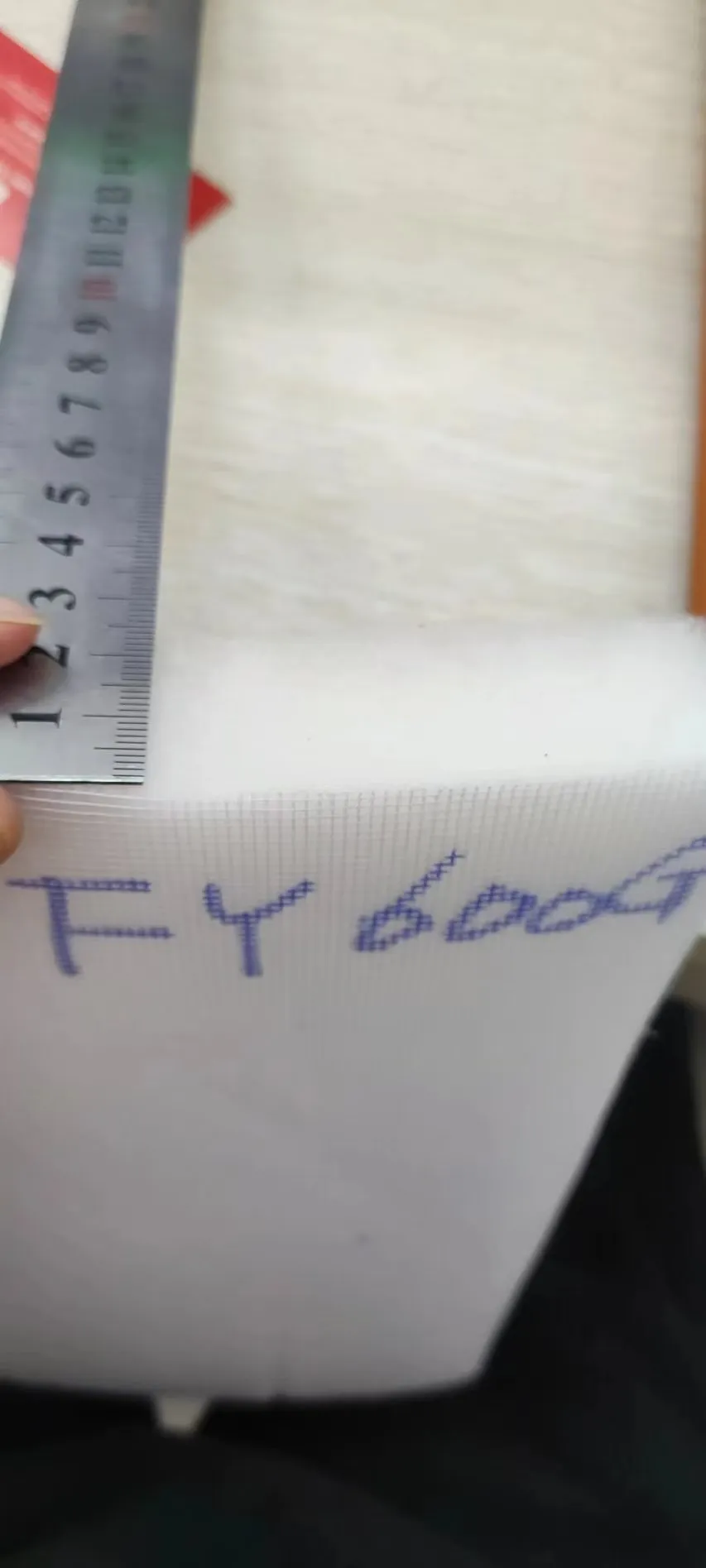

- Cutting and Sizing: The large rolls of filter media are cut into specific dimensions based on standard industry sizes (e.g., 20″ x 20″, 24″ x 24″, 2m x 20m rolls) or custom client requirements. Precision cutting ensures a snug fit within filter frames, preventing bypass.

- Quality Control and Testing: Each batch undergoes rigorous testing to meet international standards such as EN 779 (F5, F6) or ISO 16890 (ePM10, ePM2.5). Key performance indicators tested include initial pressure drop, average arrestance, dust holding capacity, and fractional filtration efficiency. This ensures consistent performance and adherence to specified MERV ratings (e.g., MERV 13-14 for ceiling filters).

- Packaging: Filters are carefully packaged to protect them from contamination and damage during transit and storage.

Typical service life for these filters ranges from 300 to 800 operational hours, highly dependent on booth usage, paint type, and pre-filtration effectiveness. Target industries include automotive refinishing, aerospace coating, furniture manufacturing, and any industrial process requiring ultra-clean air for surface finishing. The technical advantages include superior dust holding capacity, consistent laminar airflow, and protection against paint finish defects, ultimately leading to energy savings by reducing rework and optimizing spray booth operational efficiency.

Industry Trends and Market Dynamics

The market for spray booth ceiling filters is continually evolving, driven by stricter environmental regulations, advancements in paint technology (e.g., waterborne paints requiring even cleaner environments), and the persistent demand for higher quality finishes. Key trends include:

- Enhanced Filtration Efficiency: A consistent push towards finer filtration, with increasing adoption of F7 (MERV 14) and even F8 (MERV 15) rated filters to capture sub-micron particles. This improves finish quality and protects workers.

- Sustainable Materials: Growing interest in filter media made from recycled content or materials that are easier to dispose of responsibly, aligning with corporate sustainability goals.

- Longer Service Life: Manufacturers are developing filters with higher dust holding capacities to extend change-out intervals, reducing maintenance costs and downtime. This often involves advanced gradient density structures and deeper impregnation with tackifiers.

- Smart Filtration Systems: Integration of IoT sensors to monitor differential pressure and filter loading in real-time, signaling optimal change-out times and predictive maintenance.

- Customization: Increasing demand for custom-sized filters and media rolls to fit non-standard booth configurations or specific application requirements.

These trends underscore the critical need for sophisticated filtration solutions that not only meet current operational demands but also anticipate future regulatory and quality benchmarks. The evolution of filter media, especially for paint booth ceiling filters, directly influences the operational efficiency and output quality of high-precision finishing lines.

Technical Specifications and Performance Parameters

Understanding the technical specifications of paint booth ceiling filters is crucial for selecting the appropriate product for a specific application. Key parameters directly impact filtration efficiency, airflow dynamics, and operational costs. Our products meet or exceed international standards for air filtration.

Typical Product Specification Table (F5/EU5 Grade)

| Parameter | Specification / Value | Standard / Test Method |

|---|---|---|

| Filter Class (EN 779:2012) | F5 (or EU5) | EN 779 |

| ISO ePM10 Efficiency (ISO 16890) | ≥ 50% | ISO 16890 |

| Average Arrestance | ≥ 96% | EN 779 |

| Initial Pressure Drop @ 0.25 m/s | < 20 Pa | EN 779 |

| Recommended Final Pressure Drop | 250 Pa | Manufacturer Guideline |

| Dust Holding Capacity (DHC) | ≥ 450 g/m² | EN 779 |

| Media Type | Progressively Structured Synthetic Fibers | Material Analysis |

| Tackifier Impregnation | Non-migratory, Dust-retaining Adhesive | Visual/Chemical Test |

| Thermal Resistance | Up to 100°C (212°F) | ASTM D648 |

| Flammability Rating | F1 (DIN 53438) | DIN 53438 |

These specifications ensure that the filters provide consistent, high-level performance, crucial for demanding industrial environments. The progressive density of the media allows for efficient particle capture across its depth, extending filter life and maintaining optimal air quality.

Application Scenarios and Technical Advantages

The versatility and high performance of spray booth ceiling filters make them indispensable across a wide range of industrial finishing applications where surface quality is paramount. Their primary function is to create a laminar airflow, free of contaminants, ensuring a flawless paint finish.

Typical Application Scenarios:

- Automotive OEM and Refinishing: Essential for painting vehicle bodies, parts, and during collision repair, where even microscopic dust can compromise the finish.

- Aerospace Manufacturing: Used in painting aircraft components and fuselages, demanding the highest level of particulate control due to stringent quality and safety standards.

- Furniture and Wood Finishing: For applying lacquers and paints to furniture, cabinets, and other wood products, preventing dust from settling on wet surfaces.

- Industrial Coating and Fabrication: In the finishing of heavy machinery, industrial equipment, and metal fabrication, where a durable and aesthetically pleasing coating is required.

- Plastics and Composites Painting: For painting plastic parts, ensuring a smooth, defect-free surface for various consumer and industrial products.

Key Technical Advantages:

- Superior Particle Arrestance: The progressively structured synthetic media, often with integrated tackifiers, efficiently captures fine dust, lint, and paint overspray particles down to 5 microns and smaller. This prevents costly paint defects like ‘fisheyes’ or ‘pinholes’.

- Optimized Laminar Airflow: Engineered for minimal pressure drop, these filters ensure a consistent, non-turbulent downdraft airflow within the booth. This creates a clean, predictable painting environment and effectively carries overspray downwards, away from the painted surface and operator.

- Extended Service Life: High dust holding capacity means fewer filter change-outs, leading to reduced maintenance costs and decreased operational downtime. This translates directly to increased productivity.

- Chemical Resistance: The synthetic media and tackifiers are designed to be resistant to common paint solvents and chemicals, maintaining integrity and performance throughout their operational life.

- Energy Efficiency: A low initial and sustained pressure drop minimizes the energy consumption of the spray booth’s fan system, contributing to significant energy savings over time.

Vendor Comparison: Choosing the Right Filtration Partner

Selecting the right supplier for spray booth ceiling filters is a strategic decision that impacts operational efficiency, product quality, and cost-effectiveness. While many vendors offer filtration products, key differentiators emerge in material quality, manufacturing consistency, technical support, and customization capabilities.

Comparative Analysis of Filtration Solutions

| Feature | Premium Grade Solution (e.g., FiltersMaterial) | Standard/Economy Solution |

|---|---|---|

| Filtration Efficiency (EN 779 F5/ISO ePM10) | Average Arrestance ≥ 96%, ISO ePM10 ≥ 50% (Consistently maintained) | Average Arrestance 90-95%, ISO ePM10 40-50% (May degrade quickly) |

| Media Construction | Progressive density, multi-layer synthetic, thermally bonded with scrim backing. | Single/dual layer, less dense media, basic thermal bonding, may lack scrim. |

| Tackifier Quality | High-grade, non-migratory, uniform impregnation, tested for stability. | Basic, potentially migratory tackifier, inconsistent application. |

| Dust Holding Capacity (DHC) | Excellent (≥ 450 g/m²), extending service life. | Moderate (< 350 g/m²), leading to frequent change-outs. |

| Initial Pressure Drop | Low (< 20 Pa), optimizing fan energy consumption. | Higher (> 25 Pa), increasing energy costs. |

| Certifications | EN 779, ISO 16890, DIN 53438 (F1), often ISO 9001 certified manufacturer. | May have basic compliance, fewer comprehensive certifications. |

| Customization Options | Extensive range of sizes, media types, and roll lengths available. | Limited to standard sizes, less flexibility. |

| Technical Support | Dedicated application engineers, comprehensive data sheets, installation guides. | Basic support, often generic information. |

Choosing a premium supplier ensures not only superior product performance but also long-term cost savings through extended filter life, reduced rework, and optimized energy consumption. Our commitment to quality, backed by years of experience in the B2B filtration market, positions us as a reliable partner for your critical finishing operations.

Customized Solutions for Unique Requirements

While standard sizes and grades of paint booth ceiling filters meet the needs of many operations, specialized industrial applications often require bespoke solutions. We understand that every spray booth has unique dimensions, airflow characteristics, and contaminant profiles. Our expertise lies in collaborating with clients to develop tailored filtration solutions that perfectly integrate with existing systems and address specific challenges.

Our Customization Capabilities Include:

- Non-Standard Dimensions: Production of filters in precise lengths and widths to fit unusual plenum sizes or custom-built spray booths, minimizing bypass and maximizing filtration area.

- Specific Media Grades: Offering a range of filtration efficiencies (e.g., F6, F7, F8) or specialized media for unique particulate challenges, such as extremely fine dust or specific chemical aerosols.

- Roll Lengths and Formats: Providing filter media in bulk rolls of varying lengths for facilities that cut their own filters, or pre-cut pads to exact specifications for immediate installation.

- Enhanced Durability: Developing filters with increased bursting strength or chemical resistance for highly aggressive environments or prolonged service intervals.

- Integrated Solutions: Advising on optimal pre-filtration stages (e.g., panel filters, pocket filters) to extend the life of ceiling filters and reduce overall filtration costs.

Our technical team works closely with clients through consultation, on-site assessment, and material analysis to design and deliver solutions that not only meet but often exceed performance expectations, ensuring maximum operational efficiency and paint finish quality.

Application Case Studies

Real-world application demonstrates the tangible benefits of high-quality filtration. Our spray booth ceiling filters have been instrumental in improving paint quality, reducing operational costs, and enhancing environmental compliance across diverse industries.

Case Study 1: Automotive OEM Assembly Plant

An automotive manufacturing plant faced recurring issues with paint finish defects, specifically microscopic dust inclusions on newly painted vehicle bodies. Their existing F5-rated filters, while meeting minimum requirements, exhibited inconsistent performance and shorter-than-expected service life. After consultation and analysis of their specific airborne particulate profile, we recommended an upgrade to a custom F7 (MERV 14) graded filter media with enhanced tackifier impregnation. This solution provided a higher average arrestance for sub-micron particles. Within three months, the plant reported a 40% reduction in paint rework rates attributable to dust defects, translating to significant savings in labor and material costs. Furthermore, the extended DHC of the new filters led to a 25% reduction in filter change-out frequency.

Case Study 2: Aerospace Component Coating Facility

A facility specializing in coating aerospace components required extremely clean environments to meet stringent FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency) standards. Their challenge was maintaining consistent class 100,000 cleanroom conditions within their paint booths. We implemented a multi-stage filtration system, leveraging our specialized F6 paint booth ceiling filters as the final stage, preceded by high-efficiency pre-filters. The filters were custom-cut to perfectly fit their modular booth design. The outcome was a sustained achievement of cleanroom standards, documented by real-time particle counters. This not only ensured compliance but also enabled the facility to process more delicate, high-value components with confidence, leading to expanded contract opportunities.

Trustworthiness & Support: Our Commitment to Clients

Building long-term partnerships in the B2B sector relies heavily on trust, transparency, and robust support infrastructure. We are committed to providing not only superior spray booth ceiling filters but also comprehensive services that ensure maximum operational uptime and client satisfaction.

Frequently Asked Questions (FAQ)

- Q: How often should I change my spray booth ceiling filters?

A: The frequency depends on booth usage, paint volume, and the effectiveness of pre-filtration. Generally, every 300-800 operational hours or when the final pressure drop reaches its recommended limit (typically 250 Pa). Consistent monitoring with a manometer is recommended. - Q: What’s the difference between F5 and F7 filters?

A: F7 filters offer higher filtration efficiency, capturing finer particles (down to sub-micron levels) compared to F5. While F5 is suitable for many standard applications, F7 is preferred for high-end finishes, sensitive products, or more demanding industry standards. - Q: Do your filters contain a tackifier?

A: Yes, most of our ceiling filter grades are impregnated with a high-quality, non-migratory tackifier to enhance dust retention and prevent particle re-entrainment into the clean airstream. - Q: Can I get custom-sized filters?

A: Absolutely. We offer extensive customization options for dimensions, roll lengths, and specific media grades to perfectly match your unique spray booth requirements.

Lead Time & Fulfillment

Standard size filters are typically available for dispatch within 3-5 business days. Custom orders or large volume requests generally require 7-14 business days, depending on complexity and material availability. We maintain strategic inventory levels to ensure rapid fulfillment for common requirements and work closely with clients on forecasting for larger projects to guarantee timely delivery. Expedited shipping options are also available upon request.

Warranty Commitments

Our paint booth ceiling filters are manufactured under stringent quality control (ISO 9001 certified processes) and come with a performance guarantee. We warrant our filters to be free from defects in material and workmanship for a period of 12 months from the date of purchase, provided they are stored, installed, and operated according to our guidelines and industry best practices. Any claims will be promptly investigated by our technical team.

Customer Support

Our dedicated technical support team is available to assist with product selection, installation guidance, troubleshooting, and custom solution development. We offer phone and email support during business hours and can arrange on-site consultations for complex projects. Our commitment extends beyond the sale, ensuring optimal performance of our filtration solutions throughout their service life.

References

- ISO 16890-1:2016 – Air filters for general ventilation — Part 1: Technical specifications, requirements and classification system based on particulate matter efficiency (ePM).

- EN 779:2012 – Particulate air filters for general ventilation — Determination of the filtration performance.

- DIN 53438-3:1984 – Testing of combustible materials; ignitability of materials for textile fabrics; edge ignition.

- ASHRAE Standard 52.2-2017 – Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size.

- National Fire Protection Association (NFPA) 33 – Standard for Spray Application Using Flammable or Combustible Materials.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog