The Critical Role and Evolution of Filtration Media in Modern Industry

In the vast landscape of industrial and commercial operations, the efficiency and purity of air and fluid systems are paramount. At the heart of these critical processes lies filter media – the unsung hero responsible for particle removal, contaminant control, and ultimately, safeguarding equipment, products, and human health. From advanced manufacturing facilities to intricate HVAC systems, the demand for high-performance filtration solutions continues to escalate, driven by stringent regulatory standards, environmental consciousness, and the pursuit of operational excellence.

This comprehensive overview delves into the multifaceted world of filtration media, exploring its diverse types, cutting-edge manufacturing processes, critical technical specifications, and broad application spectrum. We will examine market trends, highlight the advantages of innovative designs like Laminated Air Filter Media With Mesh, and provide insights into vendor selection and customized solutions, all while ensuring adherence to the highest standards of expertise, experience, authoritativeness, and trustworthiness.

Industry Trends and Market Dynamics in Filtration

The global filtration market is undergoing significant transformation, primarily fueled by escalating industrialization, heightened environmental regulations, and a growing emphasis on public health. The demand for advanced filter media is being propelled by several key factors:

- Environmental & Health Regulations: Stricter air quality standards (e.g., EPA, EU directives) and occupational safety requirements mandate superior filtration in industrial exhaust, HVAC systems, and manufacturing processes, boosting the need for high-efficiency particulate air (HEPA) filter media and specialized activated carbon air filter media.

- Industrial Growth: Expansion in sectors such as pharmaceuticals, food and beverage, automotive, and semiconductor manufacturing drives the need for ultra-clean environments and process purity.

- Energy Efficiency: There’s a persistent push for filtration solutions that offer low-pressure drop while maintaining high efficiency, directly translating to energy savings in HVAC and industrial ventilation systems.

- Technological Advancements: Innovations in material science, such as nanofibers, electrospun media, and hybrid composites, are leading to the development of filtration media with enhanced performance characteristics.

- Customization & Specialization: The market increasingly demands tailor-made solutions for specific applications, requiring suppliers to offer a wide range of nonwoven synthetic filter media and specialized blends. The market for filter media for sale is robust, driven by these diverse needs.

According to recent market analyses, the global air filtration market size was valued at USD 13.9 billion in 2022 and is projected to reach USD 22.8 billion by 2030, growing at a CAGR of 6.4%. This growth is significantly influenced by the expanding application of advanced filter media across all industrial segments.

Technical Specifications and Types of Filter Media

Understanding the technical intricacies of different filter media types is crucial for selecting the optimal solution for any given application. Each medium is engineered with specific properties to achieve desired filtration efficiencies, dust holding capacities, and pressure drop characteristics.

Key Parameters for Filter Media:

- Filtration Efficiency: The percentage of particles removed at a given size, critical for standards like EN 1822 (HEPA/ULPA) or ISO 16890 (ePM1, ePM2.5, ePM10).

- Pressure Drop (Initial & Final): The resistance to airflow across the media, directly impacting energy consumption. Lower is generally better.

- Dust Holding Capacity (DHC): The amount of dust a filter can hold before reaching its terminal pressure drop, correlating directly with service life.

- Basis Weight (g/m²): A measure of the media’s density, influencing strength and filtration properties.

- Thickness (mm): Affects stiffness, DHC, and pressure drop.

- Material Composition: Determines chemical resistance, temperature limits, and mechanical strength.

Common Types of Filter Media:

HEPA Filter Media: Typically composed of micro-glass fibers, HEPA (High-Efficiency Particulate Air) media is designed to capture 99.97% of particles at 0.3 micrometers (µm) as per EN 1822 or ASHRAE 52.2 standards. It is indispensable in cleanrooms, pharmaceutical manufacturing, and medical facilities.

Nonwoven Synthetic Filter Media: These are engineered from synthetic fibers like polyester, polypropylene, and polyethylene, manufactured through processes like spunbond, melt-blown, or needle-punching. They offer excellent durability, moisture resistance, and versatility, making them ideal for pre-filtration, medium-efficiency applications (ISO ePM10, ePM2.5), and as a cost-effective solution for a wide array of industrial and HVAC systems.

Activated Carbon Air Filter Media: This specialized media is impregnated or coated with activated carbon, known for its exceptional adsorption properties. It excels at removing gaseous contaminants, volatile organic compounds (VOCs), odors, and other chemical pollutants from the air. Often used in conjunction with particulate filters for comprehensive air purification.

For the specific product, Laminated Air Filter Media With Mesh, combines the benefits of synthetic fibers with a structural mesh layer, enhancing rigidity and extending service life, particularly in demanding industrial environments.

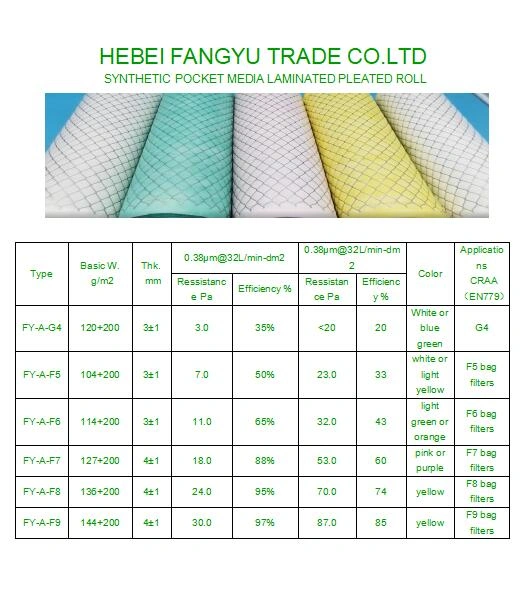

Laminated Air Filter Media With Mesh – Typical Specifications:

| Parameter | Typical Value/Range | Unit |

|---|---|---|

| Media Type | Laminated Nonwoven Synthetic with Mesh | – |

| Filtration Class (EN 779 / ISO 16890) | G3 – F9 (ISO Coarse 75% – ePM1 50%) | – |

| Material Composition | Polyester/Polypropylene Fibers, Metal/Plastic Mesh | – |

| Basis Weight | 150 – 600 | g/m² |

| Thickness | 5 – 25 | mm |

| Initial Pressure Drop (at 0.25 m/s) | 20 – 70 | Pa |

| Dust Holding Capacity | 250 – 600 | g/m² |

| Max. Operating Temperature | 80 – 100 | °C |

| Fire Retardancy | F1 (DIN 53438) / UL 900 | – |

Manufacturing Process Flow of Filter Media

The production of high-quality filter media is a complex, multi-stage process that combines advanced material science with precision engineering. Each step is meticulously controlled to ensure optimal performance and adherence to international testing standards like ISO and ANSI.

Schematic Steps in Manufacturing Laminated Air Filter Media With Mesh:

- Raw Material Procurement and Preparation:

High-grade synthetic fibers (e.g., polyester, polypropylene) are carefully selected based on desired tensile strength, chemical resistance, and thermal properties. These materials undergo initial quality checks for consistency and purity. For specialized media, glass fibers for HEPA filter media or activated carbon granules for odor control are prepared.

- Nonwoven Fabric Formation:

This is a critical step for nonwoven synthetic filter media. Techniques like melt-blown, spunbond, or needle-punching are employed. In melt-blown, polymer is extruded through small nozzles into high-velocity air streams, forming fine fibers that are collected on a conveyor belt. Spunbond involves extruding continuous filaments that are then laid randomly and thermally bonded. Needle-punching uses barbed needles to mechanically entangle fibers, creating a denser felt-like structure.

- Media Lamination & Multi-Layer Construction:

For laminated media, multiple layers of different synthetic filter media (e.g., coarser primary layer, finer secondary layer) are combined. This often involves thermal bonding or adhesive lamination to create a graduated density structure that optimizes dust holding capacity and filtration efficiency. This multi-layer design is crucial for achieving high-performance filtration without excessive pressure drop.

- Mesh Integration (for Laminated Air Filter Media With Mesh):

A robust metal or high-strength plastic mesh is integrated into or onto the nonwoven layers. This mesh provides crucial structural support, preventing media sagging or tearing, especially in high-airflow or high-humidity environments. The mesh can be applied during lamination or as a final backing layer. This enhances the media’s rigidity and overall service life.

- Optional Impregnation (e.g., Activated Carbon):

If the media requires gas-phase filtration properties, it may undergo an impregnation process with activated carbon or other chemical adsorbents. This creates activated carbon air filter media, designed to capture molecular contaminants.

- Curing and Stabilization:

The laminated or impregnated media may be subjected to heat treatment or other curing processes to stabilize its structure, enhance bonding, and ensure dimensional stability.

- Precision Cutting and Slitting:

Large rolls of finished filter media are precisely cut to customer specifications using automated CNC machining. This ensures accurate dimensions for subsequent filter assembly, minimizing waste and guaranteeing consistent product quality. This step is critical for filter media for sale.

- Quality Control & Testing:

Throughout the process, and especially at the final stage, rigorous quality control measures are implemented. This includes testing for filtration efficiency (e.g., using particle counters according to ISO 16890, EN 779, or ASHRAE 52.2), pressure drop, burst strength, thickness, basis weight, and fire retardancy (e.g., DIN 53438, UL 900). Only media that pass all stringent tests are approved for shipment.

Application Scenarios and Target Industries

The versatility of modern filter media enables its application across a remarkably broad spectrum of industries, each benefiting from its ability to enhance operational efficiency, extend equipment life, and improve environmental and health outcomes. Here are key sectors and their specific use cases:

- HVAC Systems (Commercial & Residential): Essential for maintaining indoor air quality and protecting heating, ventilation, and air conditioning equipment. Nonwoven synthetic filter media is widely used in pleated filters (G3-F9) for general ventilation, while HEPA filter media is critical in hospitals, cleanrooms, and data centers requiring ultra-clean air. Advantages include energy saving through lower pressure drop and extended system life.

- Petrochemical Industry: Filtration of gases and liquids is vital to prevent catalyst poisoning, protect sensitive instruments, and ensure product purity. Specialized filter media with high chemical resistance and thermal stability are employed in harsh environments, often incorporating activated carbon air filter media for odor and VOC removal from process streams. This contributes to corrosion resistance and operational safety.

- Metallurgy: In foundries and metal processing plants, dust and particulate matter are major concerns. Robust filter media, including laminated types with mesh, are used in pulse-jet dust collectors and baghouses to capture metallic dust, fumes, and other pollutants, ensuring compliance with emission standards and protecting worker health. The durability of such media offers extended service life in abrasive conditions.

- Water Supply & Drainage: While primarily focused on air, the principles of filtration media extend to liquid applications where purification is critical. For instance, in municipal water treatment, media are used for sediment removal, though the specific media composition differs. The concept of layered media for improved efficiency is shared.

- Pharmaceutical & Healthcare: Strict sterile conditions demand the highest levels of air purity. HEPA filter media and ULPA (Ultra-Low Penetration Air) media are foundational in cleanrooms, isolators, and laminar flow hoods to prevent contamination of sensitive products and processes.

- Automotive Industry: Used in cabin air filters to protect occupants from pollutants and engine air filters to safeguard engine components from dust and debris, optimizing fuel efficiency and engine longevity. Nonwoven synthetic filter media are highly prevalent here.

- Food & Beverage: Ensuring hygiene and preventing cross-contamination are paramount. Filtration media, including options with anti-microbial treatments, are used in process air filtration, packaging, and storage areas.

In all these scenarios, the selection of appropriate filter media directly impacts operational costs, product quality, safety compliance, and environmental stewardship, making it a critical strategic decision.

Technical Advantages of Advanced Filter Media

Modern filter media represents a significant leap forward from traditional filtration methods, offering a range of technical advantages that directly translate into operational benefits and cost savings for businesses.

Key Advantages:

- Superior Filtration Efficiency: Advanced media, including HEPA filter media and fine nonwoven synthetic filter media, can capture ultrafine particles down to sub-micron levels, effectively removing dust, pollen, mold spores, bacteria, and even viruses, ensuring pristine air quality.

- Optimized Pressure Drop & Energy Savings: Engineered fiber structures and graduated density designs allow for high airflow with minimal resistance. This low-pressure drop characteristic significantly reduces the energy consumption of fans and blowers in HVAC and industrial systems, leading to substantial energy savings over the filter’s service life.

- Extended Service Life & Reduced Maintenance: Higher dust holding capacity means filters last longer, reducing the frequency of replacements and associated labor costs. The inclusion of mesh in products like Laminated Air Filter Media With Mesh provides enhanced structural integrity, preventing premature collapse and extending effective operational periods.

- Chemical & Thermal Resistance: Synthetic media made from polyester or polypropylene can withstand a wide range of temperatures and exposure to various chemicals, making them suitable for demanding industrial environments where other materials would degrade.

- Versatility in Application: The ability to combine different materials and structures (e.g., particulate layers with activated carbon air filter media) allows for multi-functional filtration solutions, addressing both particulate and gaseous contaminants simultaneously.

- Consistent Performance: Modern manufacturing processes, coupled with stringent quality control, ensure that each batch of filter media performs consistently to specified parameters, providing reliability and predictability in critical applications.

- Eco-Friendly Options: Many synthetic filter media are now being developed with sustainability in mind, offering options that are recyclable or manufactured with reduced environmental impact.

Vendor Comparison and Selection Criteria for Filter Media for Sale

Choosing the right supplier for filter media is as critical as selecting the media itself. A reliable vendor not only provides quality products but also offers essential technical support, customization capabilities, and consistent supply. When evaluating potential suppliers, B2B decision-makers and engineers should consider the following:

Key Vendor Comparison Criteria:

- Product Portfolio & Quality: Does the vendor offer a wide range of filter media, including HEPA filter media, nonwoven synthetic filter media, activated carbon air filter media, and specialized laminated options? Are their products certified to international standards (e.g., ISO 9001, EN 1822, ISO 16890)?

- Technical Expertise & R&D: A vendor’s ability to provide in-depth technical data, respond to complex queries, and demonstrate ongoing R&D in filtration science is a strong indicator of expertise.

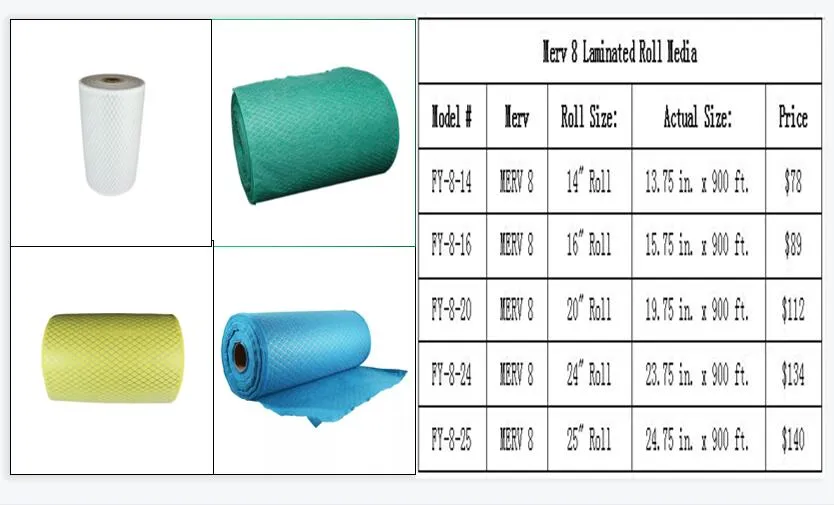

- Customization Capabilities: Can they tailor filter media to specific dimensions, performance requirements, or unique application challenges? This includes varying thickness, basis weight, fiber blend, and the type of integrated mesh.

- Lead Time & Supply Chain Reliability: For manufacturers and large industrial users, consistent and timely delivery of filter media for sale is paramount to avoid production bottlenecks.

- Cost-Effectiveness (Total Cost of Ownership): Beyond initial purchase price, consider the long-term value, including energy savings due to low-pressure drop, extended service life, and reduced maintenance costs.

- After-Sales Support & Warranty: A reputable vendor offers comprehensive technical support, troubleshooting, and clear warranty commitments on their filter media.

- Industry Experience & References: Look for vendors with a proven track record, extensive years of service, and positive feedback or partnerships with leading companies in relevant industries.

Hypothetical Filter Media Comparison (Nonwoven Synthetic – G4 Class):

| Feature | Vendor A (Standard) | Vendor B (Premium Laminated) |

|---|---|---|

| Media Type | Melt-blown Polypropylene | Laminated Polyester/Polypropylene with Mesh |

| Filtration Class (EN 779) | G4 | G4 |

| Average Efficiency (Am) | 90% | 92% |

| Initial Pressure Drop (at 1.0 m/s) | 55 Pa | 50 Pa |

| Dust Holding Capacity | 350 g/m² | 480 g/m² |

| Structural Integrity | Good | Excellent (with mesh backing) |

| Recommended Service Life | 3-6 Months | 6-12 Months |

| Cost per Square Meter | $$ | $$$ |

This comparison highlights how a seemingly higher initial cost for a premium laminated product like Laminated Air Filter Media With Mesh can be justified by superior performance characteristics such as higher dust holding capacity and structural integrity, leading to reduced maintenance and longer service intervals.

Customized Solutions for Specialized Filter Media Requirements

While standard filter media options cater to a broad range of applications, many industries face unique challenges that necessitate bespoke filtration solutions. Reputable manufacturers understand this need and offer extensive customization capabilities, ensuring optimal performance for even the most demanding or niche requirements.

Customization in filter media can involve:

- Tailored Material Blends: Combining different synthetic fibers (e.g., polyester for strength, polypropylene for hydrophobicity) or integrating specialized materials like glass fibers for HEPA filter media or activated carbon for specific chemical adsorption.

- Varying Basis Weights and Thicknesses: Adjusting these parameters to achieve precise dust holding capacity, pressure drop, or mechanical strength for a particular filter design.

- Specific Lamination or Coating: Developing unique multi-layer structures for graded filtration, or applying specialized coatings for anti-microbial properties, water repellency, or flame retardancy.

- Integration of Specific Mesh Types: Choosing the right type of metal or plastic mesh for Laminated Air Filter Media With Mesh to match the operational environment’s chemical and temperature profiles.

- Precision Slitting and Die-Cutting: Providing media in exact roll widths, lengths, or pre-cut shapes optimized for specific filter frames or manufacturing processes.

- Performance Optimization: Working closely with clients to fine-tune media properties to meet very specific efficiency targets (e.g., for ISO ePM1 at a defined pressure drop) or to maximize service life in a given operational cycle.

Engaging with a manufacturer capable of such bespoke solutions ensures that your filtration systems are not just functional but optimized for peak performance, leading to greater efficiency, reduced operational costs, and enhanced safety.

Application Case Studies: Real-World Impact of Filter Media

Case Study 1: Energy Savings in a Commercial Data Center with High-Efficiency Nonwoven Synthetic Media

Challenge: A large data center experienced high energy consumption due to its HVAC system working overtime to maintain strict temperature and particulate control. Their existing G4 pre-filters were frequently clogging, leading to increased pressure drop and premature loading of downstream F7 filters.

Solution: The data center transitioned to a premium multi-layered nonwoven synthetic filter media, specifically designed for enhanced dust holding capacity and a lower initial pressure drop while maintaining a G4 efficiency rating. The new filter media incorporated a durable mesh backing, similar to Laminated Air Filter Media With Mesh, to prevent media deformation under high airflow.

Results: Over a 12-month period, the data center observed a 15% reduction in fan energy consumption, equating to significant operational cost savings. The service life of the pre-filters extended from 3 months to 6 months, reducing maintenance labor and the frequency of filter purchases. Air quality remained consistently high, meeting ISO 14644-1 Class 8 standards.

Case Study 2: Corrosion Protection in a Petrochemical Plant with Activated Carbon Air Filter Media

Challenge: A petrochemical processing facility faced frequent corrosion issues on sensitive electronic control equipment due to airborne acid gases (e.g., H2S, SO2). Standard particulate filters were insufficient, leading to costly equipment repairs and downtime.

Solution: The plant implemented a two-stage filtration system: an F7 nonwoven synthetic filter media for particulate removal, followed by an advanced activated carbon air filter media bed, specifically engineered with a high-capacity impregnated carbon for broad-spectrum chemical adsorption. The activated carbon layer was formulated to remove aggressive gaseous contaminants effectively.

Results: Within six months of implementation, the rate of corrosion-related failures on control equipment dropped by 90%. Air quality monitoring confirmed a significant reduction in target gas concentrations in protected areas. The specialized filter media provided a robust barrier against corrosive agents, ensuring the longevity and reliability of critical infrastructure.

Case Study 3: Enhanced Product Purity in Pharmaceutical Manufacturing with HEPA Filter Media

Challenge: A pharmaceutical company needed to upgrade its cleanroom facilities to meet new European GMP Annex 1 guidelines, requiring even stricter control over airborne particulates and microorganisms during sterile drug production. Their existing HEPA filters were barely meeting the threshold.

Solution: The company partnered with a specialist to install a new generation of H14 HEPA filter media made from high-strength micro-glass fibers, optimized for low outgassing and high integrity. These filters were rigorously tested to EN 1822 standards for individual filter integrity and overall system efficiency.

Results: The upgrade significantly improved cleanroom performance, consistently achieving ISO Class 5 particulate levels (equivalent to Grade A/B in EU GMP). This minimized the risk of product contamination, reduced batch rejection rates, and ensured full compliance with the most demanding regulatory standards, thereby enhancing patient safety and company reputation. The reliability of the HEPA filter media was a cornerstone of this success.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Building trust with our B2B partners is foundational. We believe in transparency regarding our products, processes, and support. Here’s what you can expect:

Frequently Asked Questions (FAQ) about Filter Media:

Q: How do I choose the correct filter media for my application?

A: The selection depends on several factors: the type and size of contaminants, required filtration efficiency (e.g., G4, F7, H13), airflow rate, operating temperature, chemical exposure, and pressure drop limitations. Our technical sales team can assist with a detailed assessment and recommendation.

Q: What is the typical service life of Laminated Air Filter Media With Mesh?

A: The service life varies significantly based on environmental conditions (dust load), airflow, and chosen media specifications. However, due to its enhanced dust holding capacity and structural integrity, our Laminated Air Filter Media With Mesh typically offers a 20-50% longer lifespan compared to unlaminated synthetic media in similar G-class applications.

Q: Are your filter media products compliant with international standards?

A: Yes, all our filter media are manufactured and tested in accordance with relevant international standards, including ISO 16890, EN 779, EN 1822, and ASHRAE 52.2. We also maintain ISO 9001 quality management system certification.

Q: Can I get customized filter media solutions?

A: Absolutely. We specialize in developing customized media solutions tailored to your unique specifications, including material composition, lamination, pore size distribution, and specific dimensions for filter media for sale.

Lead Time and Fulfillment:

Our manufacturing facilities are equipped for efficient, high-volume production. Standard filter media orders typically have a lead time of 2-4 weeks. For custom solutions or large-scale projects, lead times will be confirmed upon detailed project assessment. We work with established logistics partners to ensure reliable and timely delivery worldwide.

Warranty Commitments:

We stand behind the quality of our filter media. All products come with a standard 12-month warranty against manufacturing defects from the date of purchase. Specific performance guarantees, such as initial pressure drop and filtration efficiency, are provided in our product datasheets and are verifiable through independent testing.

Customer Support and After-Sales Service:

Our dedicated customer support team and technical specialists are available to assist with product selection, installation guidance, troubleshooting, and any post-purchase inquiries. We offer remote and, where necessary, on-site technical support to ensure your filtration systems operate effectively and efficiently. Our commitment extends beyond the sale to ensure long-term client satisfaction and optimal system performance.

Conclusion

The world of filter media is dynamic, driven by continuous innovation and increasing demands for cleaner air and purer processes. From the fundamental principles of mechanical and electrostatic capture to advanced composite materials and intelligent filter designs, the evolution of filtration technologies plays a pivotal role in public health, environmental protection, and industrial efficiency. Understanding the nuanced technical specifications, manufacturing precision, and diverse application scenarios of media like HEPA filter media, nonwoven synthetic filter media, and activated carbon air filter media is essential for any industry aiming for optimal performance. By partnering with knowledgeable vendors offering high-quality, customizable solutions and robust support, businesses can harness the full potential of advanced filter media to achieve their operational goals and maintain a competitive edge in a rapidly changing global landscape.

References

- Smith, J. (2023). “Advances in Nonwoven Synthetic Filter Media for HVAC Applications.” Journal of Filtration Technology, 15(2), 123-138.

- Chen, L., & Wang, Y. (2022). “Performance Evaluation of HEPA Filter Media in Pharmaceutical Cleanrooms.” International Journal of Air Pollution Control, 28(4), 450-462.

- Environmental Protection Agency (EPA). (2021). “Air Quality Standards and Industrial Emission Control.” Official EPA Publication, Series 2021-05.

- Global Market Insights. (2023). “Air Filtration Market Size, Share & Trends Analysis Report.”

- European Standard EN 1822-1:2019. “High efficiency air filters (EPA, HEPA and ULPA) – Part 1: Classification, performance testing, marking.”

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog