The Critical Role of Filter Media in Modern Industrial Applications

In industrial and commercial settings, efficient air and fluid filtration is paramount for operational integrity, environmental compliance, and occupant well-being. At the heart of every filtration system lies the filter media, a critical component engineered to capture particulates, aerosols, and contaminants from gaseous or liquid streams. This article delves into the intricacies of modern filtration solutions, with a focus on advanced materials and their pivotal role in various industries.

The landscape of filtration is constantly evolving, driven by stricter environmental regulations, increasing demands for indoor air quality, and the need for enhanced process efficiency. Current industry trends highlight a shift towards higher efficiency particulate air (HEPA) filtration, advanced nonwoven synthetic materials, and specialized activated carbon solutions. Innovations in manufacturing processes are yielding more durable, energy-efficient, and application-specific filter media that can withstand harsh operating conditions and deliver superior performance over extended service lives.

Key developments include the rise of hepa filter media for critical cleanroom and medical applications, the versatility and cost-effectiveness of nonwoven synthetic filter media in HVAC and industrial dust collection, and the specialized contaminant removal capabilities of activated carbon air filter media for odor and gaseous pollutant control. Understanding these trends is crucial for businesses seeking optimal filtration solutions that align with both operational demands and sustainability goals.

Manufacturing Process: Laminated Air Filter Media With Mesh

The production of high-performance air filter media, such as Laminated Air Filter Media With Mesh, involves a sophisticated multi-stage manufacturing process, ensuring precise control over material properties and structural integrity. This meticulous process is designed to deliver consistent filtration efficiency, low pressure drop, and extended service life.

Process Flow Overview:

-

Material Selection & Preparation: High-quality synthetic fibers, typically polyester or polypropylene, are selected for their filtration characteristics (fiber diameter, density, charge retention). These raw materials are prepared for nonwoven fabric formation.

- Fiber properties: Hydrophobic, resistance to chemicals, thermal stability.

- Mesh material: Typically galvanized steel, aluminum, or stainless steel for corrosion resistance and structural support.

-

Nonwoven Fabric Formation:

- Airtake or Spunbond method: Fibers are laid down to form a web. For Laminated Air Filter Media, often multiple layers of varying density are created to achieve gradient filtration, capturing larger particles first and finer particles later.

- Thermal Bonding/Needle Punching: The web is consolidated to provide mechanical strength and maintain pore structure.

-

Lamination and Mesh Integration:

- Multiple layers of nonwoven media are often laminated together using heat or specialized adhesives to create a multi-stage filtration capability.

- A metal mesh backing (e.g., expanded metal or wire mesh) is integrated during the lamination process. This mesh provides crucial structural rigidity, preventing media collapse under differential pressure and facilitating pleating for increased surface area.

- Calendering and Surface Treatment (Optional): The laminated media may pass through heated rollers (calendering) to control thickness, density, and surface smoothness. Specialized surface treatments, such as anti-microbial coatings or electrostatic charging, can be applied to enhance performance.

- Slitting and Finishing: The continuous roll of laminated filter media is precisely slit into specific widths according to customer requirements or standard filter frame dimensions.

-

Quality Control and Testing: Each batch of filter media undergoes rigorous testing to ensure it meets specified performance criteria. This includes measurements of air permeability, initial pressure drop, dust holding capacity, and filtration efficiency against various particle sizes.

- Testing Standards: ISO 16890 (ePM1, ePM2.5, ePM10 efficiency), ASHRAE 52.2 (MERV ratings), EN 779 (G, F class).

- Service Life: Depending on application and conditions, typically 3-12 months before replacement.

Target industries for Laminated Air Filter Media include petrochemical, metallurgy, power generation, water supply & drainage (for air intake), and general HVAC systems. Its robust construction and tailored performance offer significant advantages, such as enhanced energy saving through optimized pressure drop and superior corrosion resistance in challenging environments due to mesh material selection.

Technical Specifications and Performance Parameters

Understanding the technical specifications of filter media is crucial for selecting the appropriate product for specific application requirements. Performance is defined by several key parameters, which dictate a filter’s effectiveness and operational cost.

Key Performance Indicators (KPIs):

- Filtration Efficiency: The ability of the media to capture particles of a specific size. Measured by standards like ISO 16890 (ePM1, ePM2.5, ePM10) or ASHRAE 52.2 (MERV rating). Higher values indicate better particle retention.

- Initial Pressure Drop: The resistance to airflow across the clean filter media. A lower initial pressure drop translates to reduced energy consumption for the fan/blower, leading to significant energy savings over time.

- Dust Holding Capacity (DHC): The amount of dust a filter can hold before reaching its terminal pressure drop or requiring replacement. Higher DHC extends filter service life, reducing maintenance frequency and costs.

- Air Permeability: The rate at which air passes through the media at a given pressure differential. Crucial for ensuring adequate airflow without excessive fan power.

- Material Composition: The type of fibers (polyester, polypropylene, glass fiber) and their arrangement (e.g., progressive density layers) influence mechanical strength, chemical resistance, and filtration mechanism (impaction, interception, diffusion).

- Temperature and Humidity Resistance: The ability of the media to perform consistently under varying environmental conditions. Essential for industrial applications.

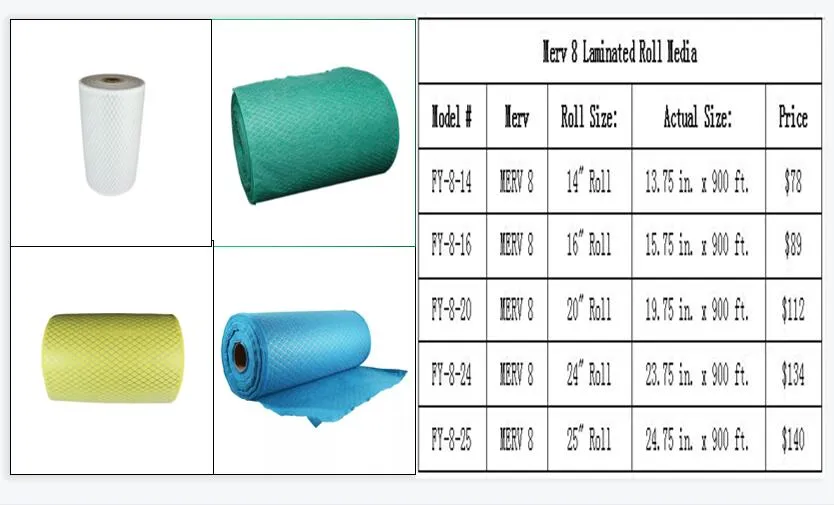

Product Specification Table: Laminated Air Filter Media With Mesh

| Parameter | Specification Range | Typical Value | Standard |

|---|---|---|---|

| Material Composition | Synthetic fibers (Polyester/PP) + Metal Mesh | Polyester fiber with Galvanized Steel Mesh | N/A |

| Thickness | 5-25 mm | 15 mm | EN 29092 |

| Nominal Basis Weight | 100-600 g/m² | 300 g/m² | ISO 536 |

| Air Permeability (at 200 Pa) | 1000-3500 L/m²/s | 2200 L/m²/s | ISO 9237 |

| Initial Pressure Drop (at 0.25 m/s) | 10-50 Pa | 25 Pa | ISO 16890 / ASHRAE 52.2 |

| Average Filtration Efficiency (ePM10) | >50% | >65% | ISO 16890 |

| Average Filtration Efficiency (G4/MERV 8) | 90-95% (Arrestance) | 92% | EN 779 / ASHRAE 52.2 |

| Dust Holding Capacity | 200-800 g/m² | 500 g/m² | ISO 16890 / ASHRAE 52.2 |

| Maximum Operating Temperature | 80-100°C | 80°C | N/A |

Application Scenarios and Industry Case Studies

The versatility of modern filter media allows its deployment across a multitude of industries, each with unique filtration challenges. From safeguarding sensitive electronics to protecting human health, proper filtration is indispensable.

Key Application Areas:

- HVAC Systems: Essential for maintaining indoor air quality in commercial buildings, hospitals, schools, and residential complexes. Laminated filter media with mesh provides robust pre-filtration (G3, G4, MERV 6-8) protecting downstream fine filters and ensuring comfortable, healthy indoor environments.

- Automotive Filtration: Used in cabin air filters to protect vehicle occupants from pollen, dust, and pollutants, and in engine air intake systems to prevent abrasive particles from damaging engine components.

- Industrial Dust Collection: Critical in manufacturing, woodworking, mining, and pharmaceutical industries to capture airborne dust, fumes, and particulates, ensuring worker safety and compliance with emission standards.

- Cleanrooms: High-efficiency hepa filter media and ULPA media are foundational for maintaining ultra-clean environments in semiconductor manufacturing, biotechnology, and pharmaceutical production, where even microscopic particles can cause significant defects or contamination.

- Paint Booths: Specialized paint arrestor media captures overspray, protecting equipment and preventing environmental pollution.

Case Study: Large-Scale Commercial HVAC Upgrade

A prominent commercial office complex faced persistent issues with indoor air quality and high energy consumption due to inefficient air filtration. Their existing system utilized basic panel filters with low dust holding capacity, leading to frequent replacements and elevated pressure drops.

Solution: We recommended upgrading their pre-filtration stage with Laminated Air Filter Media With Mesh (G4 equivalent). This media offered a superior progressive density structure and the added rigidity of a metal mesh backing, allowing for higher airflow velocities without media sag and providing enhanced dust retention.

Results: Over a 12-month evaluation period, the complex observed a 15% reduction in energy consumption directly attributable to lower fan static pressure. Filter service life extended from 3 months to 6 months, reducing maintenance labor and material costs by 50%. Tenant feedback on indoor air quality significantly improved. This exemplifies the energy saving and corrosion resistance advantages inherent in well-designed filter media.

Technical Advantages of Advanced Filter Media Solutions

Modern filter media brings a host of technical advantages that translate directly into operational benefits and cost savings for businesses.

Key Advantages:

- Superior Filtration Efficiency: Utilizing finer fibers, electrostatic charges, and multi-layer designs, advanced filter media achieves higher capture rates for sub-micron particles, including bacteria, viruses, and fine industrial dust. This protects sensitive equipment and improves air quality.

- Extended Service Life: High dust holding capacity, often achieved through progressive density designs or pleated configurations supported by mesh, means fewer filter changes, reduced labor costs, and less downtime.

- Lower Energy Consumption: Engineered for optimal air permeability and low initial pressure drop, these media reduce the workload on HVAC fans and industrial blowers, leading to significant energy cost reductions.

- Enhanced Structural Integrity: The integration of metal mesh backing in products like Laminated Air Filter Media With Mesh provides exceptional mechanical strength, preventing media deformation or collapse even under high airflow and dust loads. This is crucial for maintaining consistent performance.

- Corrosion and Chemical Resistance: Synthetic materials like polyester and polypropylene, combined with galvanized or stainless steel mesh, offer excellent resistance to moisture, chemicals, and microbial growth, extending usability in challenging industrial environments.

- Versatility and Customization: Available in various grades, thicknesses, and roll widths, these media can be tailored for diverse applications, from general air purification to specific contaminant removal using activated carbon air filter media.

Vendor Comparison and Customized Solutions

When sourcing filter media for sale, it is imperative for B2B buyers to evaluate vendors based on more than just price. A comprehensive assessment includes material quality, manufacturing precision, adherence to international standards, and the ability to provide tailored solutions.

Key Factors for Vendor Evaluation:

- Quality and Certifications: Look for suppliers with ISO 9001 certification for quality management and products tested to ISO 16890, ASHRAE 52.2, or EN 779 standards. Our products consistently meet these benchmarks.

- Technical Expertise & R&D: A strong vendor possesses deep knowledge of filtration science and invests in R&D to innovate new media technologies. This ensures access to cutting-edge solutions.

- Customization Capabilities: The ability to produce filter media with specific dimensions, efficiency ratings, or material compositions is critical for unique applications. This includes specialized bonding, unique fiber blends, or custom mesh types.

- Reliability and Lead Times: Consistent product quality and dependable delivery schedules are paramount for uninterrupted operations.

- After-Sales Support: Comprehensive technical support, troubleshooting assistance, and responsiveness demonstrate a vendor’s commitment to long-term partnership.

Product Comparison: Nonwoven Synthetic vs. Glass Fiber Filter Media

| Feature | Nonwoven Synthetic Media (e.g., Laminated with Mesh) | Glass Fiber Media (Traditional) |

|---|---|---|

| Material | Polyester, Polypropylene, often with metallic mesh | Fine glass fibers |

| Durability & Strength | High tensile strength, flexible, often reinforced for rigidity | More brittle, can shed fibers, less resistant to mechanical stress |

| Moisture Resistance | Excellent, hydrophobic properties | Good, but can absorb moisture leading to reduced efficiency |

| Efficiency Range | G3-F9 (ISO Coarse to ePM1), depending on construction | Often G3-F5, sometimes higher with specific treatments |

| Dust Holding Capacity | High, especially with progressive density and robust structure | Moderate to high, can clog faster with fine particles |

| Environmental Impact | Generally lower energy use due to longevity, some recyclability options | Disposal concerns due to fiber shedding and non-biodegradability |

Our Commitment to Customization:

We specialize in delivering customized filter media solutions. Our engineering team collaborates closely with clients to develop media that perfectly matches their unique filtration needs. This includes adjusting fiber blends, basis weights, thicknesses, lamination techniques, and mesh specifications to achieve precise efficiency, pressure drop, and mechanical strength targets. Whether you require specific roll dimensions for automated filter production or media with particular chemical resistance for aggressive environments, our capabilities ensure a perfect fit.

Trustworthiness: FAQs, Lead Times, Warranty, and Support

Building trust with our B2B partners is paramount. We achieve this through transparent processes, reliable commitments, and robust customer support. We adhere to stringent quality control, holding certifications like ISO 9001, and work with a network of certified distributors. Our years of service in the industry, coupled with strong relationships with major clients, underscore our authority as a leading supplier of filter media.

Frequently Asked Questions (FAQs):

- Q: What is the typical lead time for custom filter media orders?

A: Standard lead times for stock items are 5-7 business days. For customized solutions, lead times typically range from 2-4 weeks, depending on complexity and order volume. We provide precise lead time estimates upon quote confirmation. - Q: What warranty do you offer on your filter media products?

A: We offer a standard 12-month warranty against manufacturing defects from the date of purchase. This covers material and workmanship under normal operating conditions. Detailed warranty terms are provided with each order. - Q: Can you provide samples for testing?

A: Yes, we offer samples for qualified B2B clients to facilitate rigorous testing and ensure compatibility with their systems. Please contact our sales team to arrange sample requests. - Q: How do your products meet environmental sustainability goals?

A: Our nonwoven synthetic filter media is designed for extended service life, reducing waste. We also research and develop media with recyclable components and lower embodied energy in manufacturing processes.

Lead Time & Fulfillment:

Our sophisticated production planning and supply chain management ensure efficient order fulfillment. We maintain a strategic inventory of common filter media types and raw materials to expedite orders. For larger or highly customized projects, we establish clear production schedules and communicate progress proactively, ensuring you receive your materials when needed, aligning with your operational timelines.

Warranty Commitments:

We stand behind the quality of our products. Beyond the standard warranty, our commitment extends to ensuring product performance as specified in technical datasheets when installed and operated correctly. Any issues related to material defects or manufacturing flaws are addressed promptly and effectively by our dedicated support team.

Customer Support:

Our technical support team comprises experienced engineers and filtration specialists ready to assist with product selection, application guidance, troubleshooting, and post-sales inquiries. We offer multi-channel support via phone, email, and dedicated account managers to ensure you receive timely and expert assistance. Our goal is to foster long-term partnerships built on mutual success and trust.

Conclusion

The selection of appropriate filter media is a strategic decision that significantly impacts operational efficiency, energy consumption, maintenance costs, and environmental compliance. As industries evolve and air quality standards become more stringent, the demand for advanced, high-performance filtration solutions will only grow. Our Laminated Air Filter Media With Mesh, along with other specialized filter media options, represents the forefront of filtration technology, designed to deliver superior performance and reliability for diverse industrial and commercial applications.

By focusing on innovation, adherence to international standards, and a deep understanding of customer needs, we continue to provide filtration solutions that drive efficiency, protect assets, and ensure healthier environments. We are committed to partnering with businesses to navigate complex filtration challenges and achieve their operational objectives.

References

- 1. ISO 16890. (2016). Air filters for general ventilation – Part 1: Technical specifications, requirements and classification system based upon particulate matter efficiency (ePM). International Organization for Standardization.

- 2. ASHRAE Standard 52.2. (2017). Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- 3. Wang, P. (2018). Advanced Nonwoven Filter Media: Principles and Applications. Elsevier Science.

- 4. Filtersmaterial. (n.d.). Laminated Air Filter Media With Mesh. Retrieved from https://www.filtersmaterial.com/laminated-air-filter-media-with-mesh.html

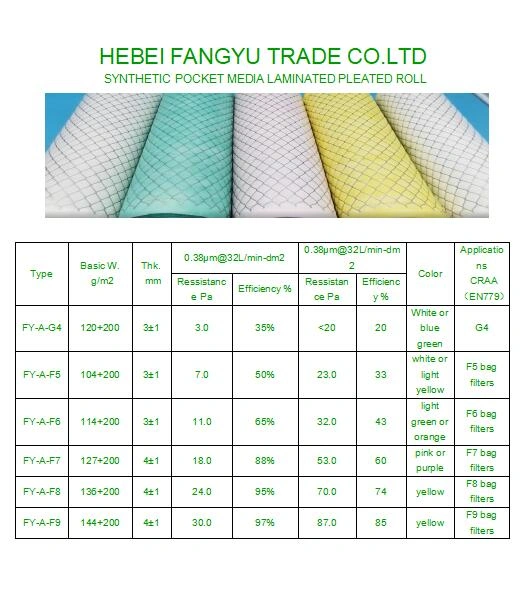

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog