The Advanced Capabilities of Polypropylene Filter Media in Industrial Filtration

In the demanding landscape of industrial filtration, the selection of an appropriate filter medium is paramount to operational efficiency, product purity, and environmental compliance. Among the various materials available, polypropylene filter media stands out due to its exceptional chemical resistance, thermal stability, and mechanical strength. This article delves into the intricate details of polypropylene as a leading filtration solution, covering its manufacturing processes, technical advantages, diverse applications, and market trends. It aims to provide B2B decision-makers and engineers with a comprehensive understanding of how this advanced material can optimize their filtration systems and contribute to sustainable industrial practices.

Manufacturing Process Flow of Advanced Polypropylene Filter Media

The production of high-performance polypropylene filter media involves a sophisticated multi-stage process designed to achieve precise pore size distribution, excellent dirt-holding capacity, and structural integrity. Our Laminated Composite Filter Media exemplifies this precision engineering.

- Raw Material Preparation: High-grade polypropylene (PP) resin granules are selected for their specific melt flow index, purity, and molecular weight. These are often combined with stabilizers and additives to enhance properties like UV resistance or hydrophobicity, depending on the application.

-

Extrusion (Casting/Melt Blown):

- Melt Blown Process: PP granules are melted and extruded through fine dies, then attenuated by high-velocity hot air to form ultrafine fibers. These fibers are collected on a conveyor belt, forming a self-bonded, gradient-density nonwoven fabric, ideal for depth filtration.

- Spunbond Process: Similar to melt-blown, but fibers are generally coarser and are drawn pneumatically, then laid onto a conveyor belt. Thermal bonding or calendering is then applied to create a strong, stable fabric.

- Lamination (for composite media): For composite media, multiple layers (e.g., melt-blown for fine filtration, spunbond for strength, and a backing layer) are thermally bonded or calendared together. This creates a multi-zone filtration structure that optimizes both particle capture efficiency and service life.

-

Post-Processing and Finishing:

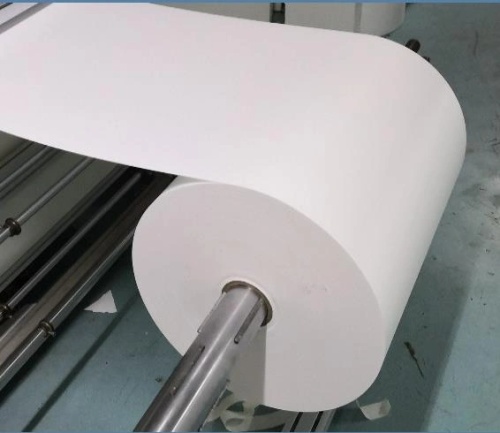

- Slitting and Winding: The broad rolls of media are precision-slit to specific widths and wound onto cores for ease of handling and integration into various filter configurations (pleated cartridges, bags, etc.).

- Pleating (for cartridges): For filter cartridges, the media is often pleated to maximize surface area within a compact design, significantly increasing dirt holding capacity and extending service life.

- Thermal Bonding/Sealing: Edges and seams are thermally bonded to prevent bypass and ensure structural integrity.

- Quality Control and Testing: Each batch undergoes rigorous testing to meet international standards such as ISO 2942 (Fluid power systems – Filters – Determination of fabrication integrity), ISO 16889 (Multi-pass method for evaluating filtration performance), and sometimes specific industry standards like FDA compliance for food & beverage applications. Tests include pore size distribution, filtration efficiency (Beta ratio), differential pressure, burst strength, and chemical compatibility.

The target industries benefiting from these processes include petrochemical, metallurgy, pharmaceutical, food and beverage, and municipal water supply & drainage. The advantages in typical application scenarios are clear: superior corrosion resistance to a wide range of chemicals, energy saving due to lower differential pressure, and extended service life minimizing change-out frequency.

Industry Trends in Filtration Technology

The global filtration market is undergoing significant evolution, driven by stricter environmental regulations, increasing demand for clean water, and advancements in manufacturing processes. Key trends include:

- Sustainability and Eco-friendliness: There is a growing emphasis on filter media that are recyclable, consume less energy during production, and offer longer service life to reduce waste. Polypropylene filter media, being thermoplastic, offers avenues for recycling and often boasts extended lifespans.

- Enhanced Efficiency and Selectivity: Industries demand higher filtration efficiency (e.g., sub-micron filtration) with minimal pressure drop. This drives innovation in fiber technology and composite media designs, such as our Laminated Composite Filter Media, to achieve superior particle capture.

- Smart Filtration Systems: Integration of sensors for real-time monitoring of differential pressure, flow rates, and media integrity is becoming more common, allowing for predictive maintenance and optimized filter change-out schedules.

- Specialized Media for Diverse Applications: Beyond general particulate removal, the market is seeing increased demand for specialized media, including those for chemical resistance, high-temperature applications, and specific biological contaminations. This is where tailored polypropylene filter media formulations excel. The rise of pet filter media for niche animal care applications and advancements in activated filter media for adsorption further diversify the landscape.

- Cost-Effectiveness and TCO Reduction: While initial purchase cost is a factor, total cost of ownership (TCO), including energy consumption, labor for change-outs, and waste disposal, is increasingly prioritized. Long-lasting and efficient media like advanced polypropylene filter media contribute significantly to TCO reduction.

Technical Specifications and Parameters

Understanding the technical parameters of polypropylene filter media is crucial for proper system design and media selection. Our Laminated Composite Filter Media is engineered to meet stringent performance requirements across various industrial sectors.

| Parameter | Value Range (Typical) | Benefit/Relevance |

|---|---|---|

| Material Composition | 100% Virgin Polypropylene Fibers | Ensures high chemical purity and broad chemical compatibility, free from binders or surfactants. |

| Micron Rating | 0.5µm to 100µm (Absolute and Nominal) | Versatility for fine particulate removal to pre-filtration. Absolute rating (e.g., 99.9% efficiency) for critical applications. |

| Operating Temperature | Up to 80°C (176°F) continuous | Suitable for a wide range of industrial process temperatures without degradation. |

| Chemical Compatibility | Resistant to most acids, alkalis, and many organic solvents (pH 1-13) | Minimizes risk of media degradation or contamination in harsh chemical environments. |

| Dirt Holding Capacity | High (e.g., >1.5 kg/m² for specific grades) | Extended service life, reducing change-out frequency and maintenance costs. |

| Differential Pressure (Clean) | Low (e.g., <0.05 bar for typical flow rates) | Minimizes energy consumption of pumps, reducing operational costs. |

| Surface Area (Pleated) | Up to 0.75 m²/10-inch cartridge (depending on pleat configuration) | Maximized filtration area in compact designs, improving flow rates and dirt capacity. |

These specifications highlight the robustness and efficiency that advanced polypropylene filter media brings to critical industrial applications. Our commitment to quality ensures that each product consistently meets or exceeds these rigorous standards.

Application Scenarios Across Key Industries

The versatility of polypropylene filter media allows its application across a broad spectrum of industries, solving complex filtration challenges. Its properties make it ideal for pre-filtration, fine filtration, and polishing in diverse liquid and gas streams.

- Petrochemical and Chemical Processing: Filtration of process water, chemical intermediates, solvents, acids, and bases. Its excellent chemical resistance ensures stability and long life even with corrosive fluids, preventing equipment damage and maintaining product purity. This includes the effective removal of catalysts, polymers, and other fine particulates.

- Water Treatment (Municipal and Industrial): Pre-filtration for RO (Reverse Osmosis) and UF (Ultrafiltration) systems, removal of suspended solids from industrial wastewater, cooling tower water, and municipal potable water. As a superior alternative to some traditional media, polypropylene filter media is a choice for water filter media suppliers seeking reliability.

- Food and Beverage: Clarification of edible oils, wines, beers, soft drinks, and juices. Filtration of utility water, process water, and CIP (Clean-in-Place) solutions. FDA-compliant polypropylene grades ensure product safety and hygiene.

- Pharmaceutical and Biotechnology: Pre-filtration of fermentation broths, cell culture media, buffers, and API (Active Pharmaceutical Ingredient) solutions. While sterile filtration often uses membrane filters, polypropylene serves as a critical pre-filter, extending the life of more expensive final filters and ensuring process integrity.

- Electronics Manufacturing: Filtration of ultra-pure water, specialty chemicals, and plating solutions used in semiconductor and PCB manufacturing. Particle contamination can severely impact product yield, making high-efficiency polypropylene a vital component.

- Metallurgy and Metal Finishing: Filtration of plating baths, pickling solutions, and rinse water, where corrosion resistance is paramount. This prevents the buildup of sludge and improves the quality of finished metal products.

Key Technical Advantages

The selection of polypropylene filter media offers distinct technical advantages that translate into significant operational benefits for industrial users:

- Broad Chemical Compatibility: Polypropylene’s inert nature means it resists attack from a wide range of acids, alkalis, and organic solvents (pH 1-13). This eliminates the risk of media degradation, ensuring consistent filtration performance and preventing contamination of the filtered fluid, unlike some cellulosic or glass fiber alternatives.

- High Dirt Holding Capacity and Graded Density: Advanced polypropylene media often feature a graded pore structure, where larger particles are trapped in outer layers and finer particles in inner layers. This maximizes the utilization of the filter depth, leading to significantly longer service life and reduced filter change-outs compared to surface filters.

- Low Extractables: Manufactured from 100% virgin polypropylene, these media typically have very low levels of extractable compounds. This is critical for applications in pharmaceuticals, food and beverage, and electronics where product purity is paramount and even trace contaminants are unacceptable.

- Cost-Effectiveness and Energy Efficiency: The combination of long service life, high flow rates with low pressure drop, and robust construction results in a lower total cost of ownership. Reduced energy consumption for pumps and less frequent maintenance cycles contribute directly to operational savings.

- Thermal Stability: While not for extremely high temperatures, polypropylene handles process temperatures up to 80°C (176°F) continuously, making it suitable for many industrial processes where other plastics might fail.

- Versatility in Formats: Available in a wide array of formats including cartridges, bags, sheets, and rolls, polypropylene filter media can be custom-engineered to fit existing filtration equipment or new system designs, offering flexibility to meet specific application requirements.

Vendor Comparison and Selection Criteria

Selecting the right supplier for polypropylene filter media is critical. While price is a factor, prioritizing quality, technical support, and customization capabilities ensures long-term value and optimal filtration performance.

| Criteria | Our Offering (Filters Material) | Typical Competitor (General) |

|---|---|---|

| Material Purity | 100% Virgin PP, no binders/surfactants, FDA compliant grades available. | Often uses recycled PP or includes binders which may leach. |

| Filtration Efficiency | High absolute ratings (e.g., >99.9% at specified micron), multi-layer composite design. | Often nominal ratings, single-layer design, lower overall efficiency. |

| Dirt Holding Capacity | Superior graded density for maximum capacity, extended service life. | Basic depth filtration, saturates quickly, frequent change-outs. |

| Technical Support | Dedicated application engineers, process optimization, pre/post-sale support. | Limited or generic support, often requires customer expertise. |

| Customization | Extensive options for micron rating, media type, dimensions, end-caps, and composite structures. | Standard product lines only, little to no custom solutions. |

| Certifications | ISO 9001, CE, material compliance with FDA, industry-specific validations. | Basic or fewer international certifications. |

When evaluating water filter media suppliers, it is crucial to look beyond the initial purchase price and consider the long-term impact on operational efficiency, product quality, and regulatory compliance. Our focus on quality, innovation, and customer-centric solutions distinguishes our offerings in the market.

Customized Solutions for Unique Requirements

Many industrial filtration challenges cannot be met with off-the-shelf solutions. Recognizing this, we specialize in providing customized polypropylene filter media designed to address specific process parameters, contamination profiles, and system configurations. Our approach involves a collaborative process:

- Detailed Needs Assessment: Our engineers work closely with clients to understand their exact requirements, including fluid properties, desired purity levels, flow rates, operating temperatures, and existing equipment constraints.

- Material Formulation and Design: Based on the assessment, we can modify the PP fiber blend, melt-blown or spunbond parameters, and composite layer structure to optimize pore size distribution, thickness, and mechanical strength. This may include adjusting the hydrophilicity or hydrophobicity of the media.

- Prototype Development and Testing: Custom prototypes are developed and rigorously tested in our labs, and often in pilot runs at the client’s facility, to validate performance against agreed-upon criteria. This iterative process ensures the final product meets all technical and operational expectations.

- Application-Specific Formats: Beyond standard cartridges, we offer customized solutions for filter bags, pleated sheets, or specialized roll goods that integrate seamlessly into unique filtration vessels or processes. This bespoke service ensures optimal fit and performance, reducing installation complexities and system downtime.

This commitment to tailored solutions empowers our clients to achieve superior filtration outcomes, even in the most challenging environments, further solidifying our position as reliable water filter media suppliers.

Application Case Studies

Real-world applications demonstrate the tangible benefits of deploying high-quality polypropylene filter media.

Case Study 1: Potable Water Treatment Plant Upgrade

A municipal water treatment plant faced issues with premature fouling of their reverse osmosis membranes due to colloidal silica and fine particulate matter in their raw water intake. Their existing sand filters and nominal cartridge filters were insufficient.

- Challenge: Reduce Silt Density Index (SDI) consistently to <3 to protect RO membranes, extend membrane lifespan, and reduce chemical cleaning frequency.

- Solution: Implemented a multi-stage pre-filtration system utilizing our 5-micron absolute rated Laminated Composite polypropylene filter media cartridges. The graded density design effectively captured a broad range of particulates.

- Results: SDI consistently maintained below 2.5. RO membrane lifespan increased by 40%, reducing replacement costs by $50,000 annually. Chemical cleaning cycles reduced by 30%, saving an additional $15,000 per year in chemical and labor costs.

Case Study 2: Chemical Plant – Acidic Process Stream Filtration

A major chemical manufacturer producing specialized polymers encountered frequent filter failures in their highly acidic (pH 2) process stream, leading to costly downtime and product batch losses. Their existing glass fiber filters were degrading rapidly.

- Challenge: Find a filter media capable of withstanding aggressive acidic conditions while maintaining consistent 10-micron filtration efficiency at 60°C.

- Solution: Switched to specifically formulated polypropylene filter media cartridges, designed for enhanced chemical resistance and thermal stability.

- Results: Filter service life extended from 2 weeks to 6 weeks, reducing filter consumption by 66%. Downtime associated with filter change-outs decreased by 75%, leading to an estimated annual production increase of 2% and significant savings in operational expenditure.

Frequently Asked Questions (FAQ)

- Q1: What are the main benefits of using polypropylene filter media over other materials?

- A1: Polypropylene offers excellent chemical resistance, high dirt-holding capacity, low extractables, and a wide range of micron ratings. It is also cost-effective due to its long service life and good flow characteristics, making it superior for many industrial applications where chemical compatibility and purity are critical.

- Q2: Is your polypropylene filter media FDA compliant?

- A2: Yes, we offer specific grades of polypropylene filter media that comply with FDA regulations for food contact materials (CFR Title 21), making them suitable for food, beverage, and pharmaceutical applications. Please specify this requirement when placing an order.

- Q3: How do I determine the correct micron rating for my application?

- A3: The appropriate micron rating depends on the particle size to be removed, desired filtrate quality, and downstream process requirements. Our technical sales team can assist you with a detailed analysis and recommendation based on your specific process fluid and application goals. We can also provide testing services.

- Q4: Can polypropylene filters be cleaned and reused?

- A4: Generally, depth-style polypropylene filter media are designed for single use due to their particle capture mechanism. While some pleated surface filters might be backwashed for limited reuse in specific applications, their efficiency typically degrades. We recommend replacement for consistent performance and purity. For applications involving activated carbon or similar, refer to activated filter media options.

Lead Time, Warranty, and Customer Support

At Filters Material, we understand the importance of timely delivery, product reliability, and responsive support for our B2B clients.

- Lead Time & Fulfillment: Standard polypropylene filter media products typically ship within 3-5 business days for in-stock items. Custom orders or large volumes may require 2-4 weeks, depending on complexity and production schedules. We maintain robust inventory levels and efficient logistics to minimize lead times and ensure on-time delivery globally. Expedited shipping options are available upon request.

- Warranty Commitments: All our polypropylene filter media products are backed by a limited warranty covering manufacturing defects and material integrity for a period of 12 months from the date of purchase. This warranty ensures that our products perform to their published specifications under normal operating conditions. Full warranty details are available upon request.

- Customer Support: Our dedicated customer support and technical sales teams are available Monday to Friday, 9:00 AM to 5:00 PM (GMT+8). We provide comprehensive pre-sales consultation, application engineering support, and prompt after-sales service. For technical inquiries, troubleshooting, or order status, please contact us via phone at +86-XXX-XXXX-XXXX or email at info@filtersmaterial.com. We are committed to ensuring your filtration systems operate effectively and efficiently.

Conclusion

Polypropylene filter media represents a cornerstone in modern industrial filtration, offering an unparalleled combination of chemical resistance, efficiency, and cost-effectiveness. From advanced manufacturing processes ensuring high purity and robust construction, to its wide array of applications across critical industries, polypropylene stands as a testament to engineering excellence in fluid management. By understanding its technical advantages, embracing customized solutions, and partnering with reliable water filter media suppliers, businesses can significantly enhance their operational efficiency, ensure product integrity, and meet stringent regulatory demands. The continuous innovation in materials science and process optimization ensures that polypropylene will remain a leading choice for demanding filtration challenges for years to come.

References

- ASTM International. (2020). ASTM D7199/D7199M-20: Standard Practice for Determining Filter Media Performance Characteristics.

- ISO (International Organization for Standardization). (2016). ISO 16889:2016: Hydraulic fluid power – Filters – Multi-pass method for evaluating filtration performance of a filter element.

- United States Food and Drug Administration. (2023). CFR Title 21 – Food and Drugs, Part 177 – Indirect Food Additives: Polymers.

- Turi, P. A. (Ed.). (1997). Polypropylene Handbook: Polymerization, Characterization, Properties, Processing, Applications. Carl Hanser Verlag.

- Filter Manufacturers Council. (2019). Filtration Handbook: A Guide to Filtration Terms and Technologies.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog