Paint Spray Booth Filter Media: field notes, specs, and what actually works

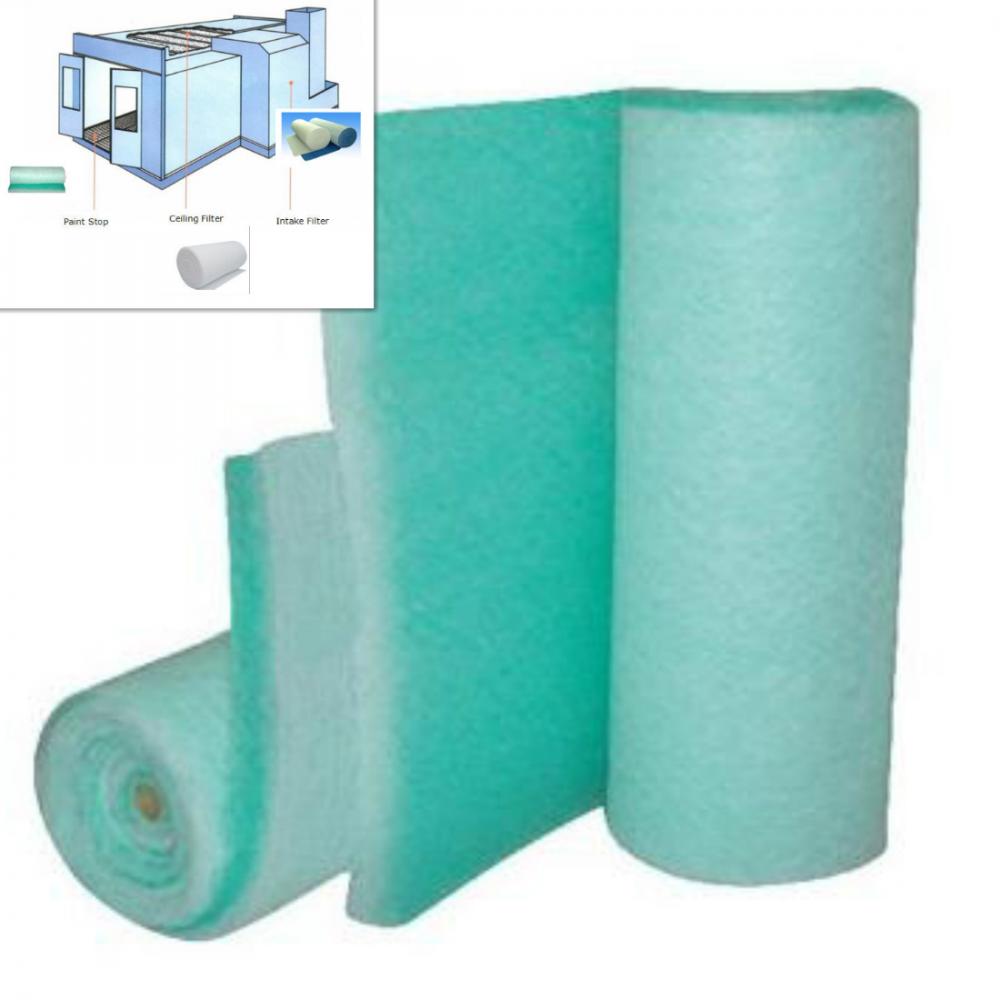

If you’ve spent time in a spray booth, you already know the quiet hero is the paint stop filter media. It’s not glamorous, but when it fails, everyone notices—overspray everywhere, fumes creeping, efficiency tanking. I’ve been in enough body shops and wood finishing lines to see what lasts and what doesn’t.

What’s changing in the market

Three quick trends: (1) more booths are aligning to ISO 16890 classifications, even for coarse overspray layers; (2) higher-temp tolerance for busy cure cycles; (3) custom pre-cut pads for faster turns. Oh, and sustainability—many buyers ask whether fiberglass mats are reclaimable. Short answer: usually not, but extended service life helps.

Core product specs (real-world focused)

Product Name: Paint Spray Booth Filter Media

Origin: Second Buliding and Studying No21 shiji street, Handan, Hebei China

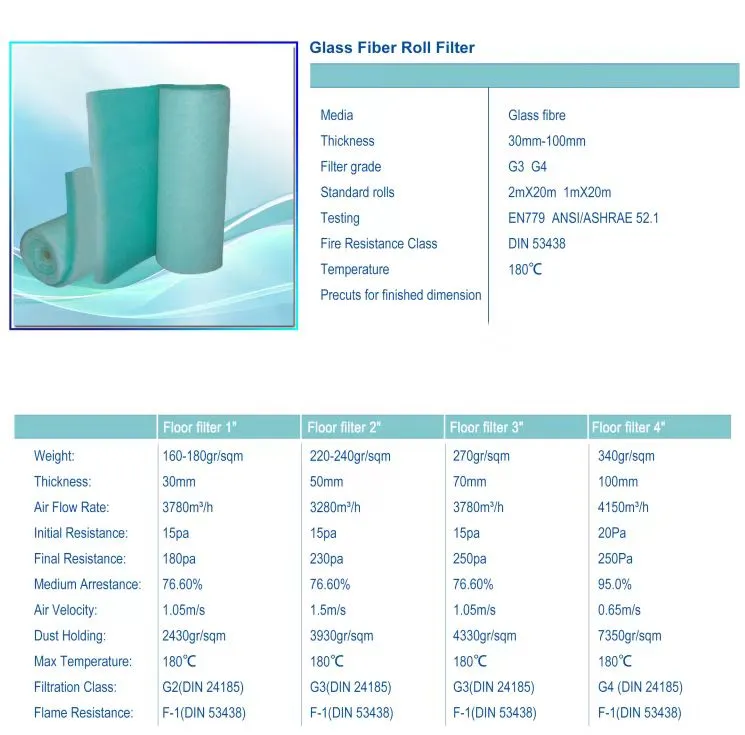

| Media | Glass fiber (progressive density) |

| Thickness | 30–100 mm |

| Filter Grade | G3–G4 (EN 779 legacy; coarse per ISO 16890) |

| Standard Rolls | 2 m × 20 m; 1 m × 20 m |

| Fire Resistance | DIN 53438 (self-extinguishing class, test-dependent) |

| Temperature | Up to 180°C |

| Initial Resistance | ≈ 25–45 Pa @ 0.5 m/s (real-world use may vary) |

| Holding Capacity | ≈ 3–5 kg/m² overspray (method-dependent) |

| Recommended Final ΔP | ≈ 200–250 Pa |

How it’s made and tested (in brief)

- Materials: long-strand glass fibers laid with progressive density; binder set for shape stability.

- Methods: wet-laid mat formation, thermal setting, precision slitting; optional pad cutting.

- Testing: ISO 16890 coarse fraction, legacy EN 779 arrestance, ASHRAE 52.2 pressure-drop curves; flame per DIN 53438.

- Service life: typically weeks to months; change at target ΔP or visible paint loading.

- Industries: automotive, rail, furniture/wood, aerospace parts, agriculture equipment, shipyards.

Where it shines

Use paint stop filter media as exhaust-floor or wall arrestor in spray booths; as a prefilter before carbon beds; or as an economical overspray layer protecting higher-grade final filters. Many customers say it keeps ductwork far cleaner—less downtime, fewer cleanouts.

Two quick case notes

Automotive refinisher, Central Europe: swapped to 50 mm paint stop filter media with tighter progressive gradient; reported ≈20% longer run time before 220 Pa. Painters noticed steadier airflow and fewer nibs.

Wood shop, Midwest US: pre-cut pads reduced changeover from 18 to 7 minutes per bay—small win that adds up. “Honestly, the time savings sold it,” the foreman told me.

Who to buy from? A practical comparison

| Vendor | Certifications | Lead Time | Customization | Typical Cost |

|---|---|---|---|---|

| This manufacturer (Hebei) | ISO 9001; DIN 53438 tested | ≈ 7–14 days | Rolls, pads, widths to order | Competitive, volume-friendly |

| Vendor A (EU) | ISO 16890 lab reports | around 2–3 weeks | Broad, but MOQ applies | Higher list price |

| Vendor B (US) | ASHRAE 52.2 data sheets | Stock-to-ship for standard sizes | Pre-cuts common | Mid-to-high |

Customization and buying tips

- Match thickness to loading: 50–75 mm is a sweet spot for most auto booths; 100 mm for heavy overspray lines.

- Request pressure-drop curves and flame test report (DIN 53438) for your file—auditors love that.

- Pre-cut pads can save shift-change minutes; ask for tolerances (±2–3 mm is typical).

To be honest, the best indicator is your manometer. When ΔP climbs to your target (say 220–250 Pa), swap the paint stop filter media and your booth—and lungs—will thank you.

References

- ISO 16890: Air filters for general ventilation.

- EN 779:2012 (legacy): Particulate air filters for general ventilation.

- DIN 53438: Testing of filter media – Fire behaviour.

- ASHRAE Standard 52.2: Method of Testing General Ventilation Air-Cleaning Devices.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog