Paint Spray Booth Filter Media: What Pros Are Using Now

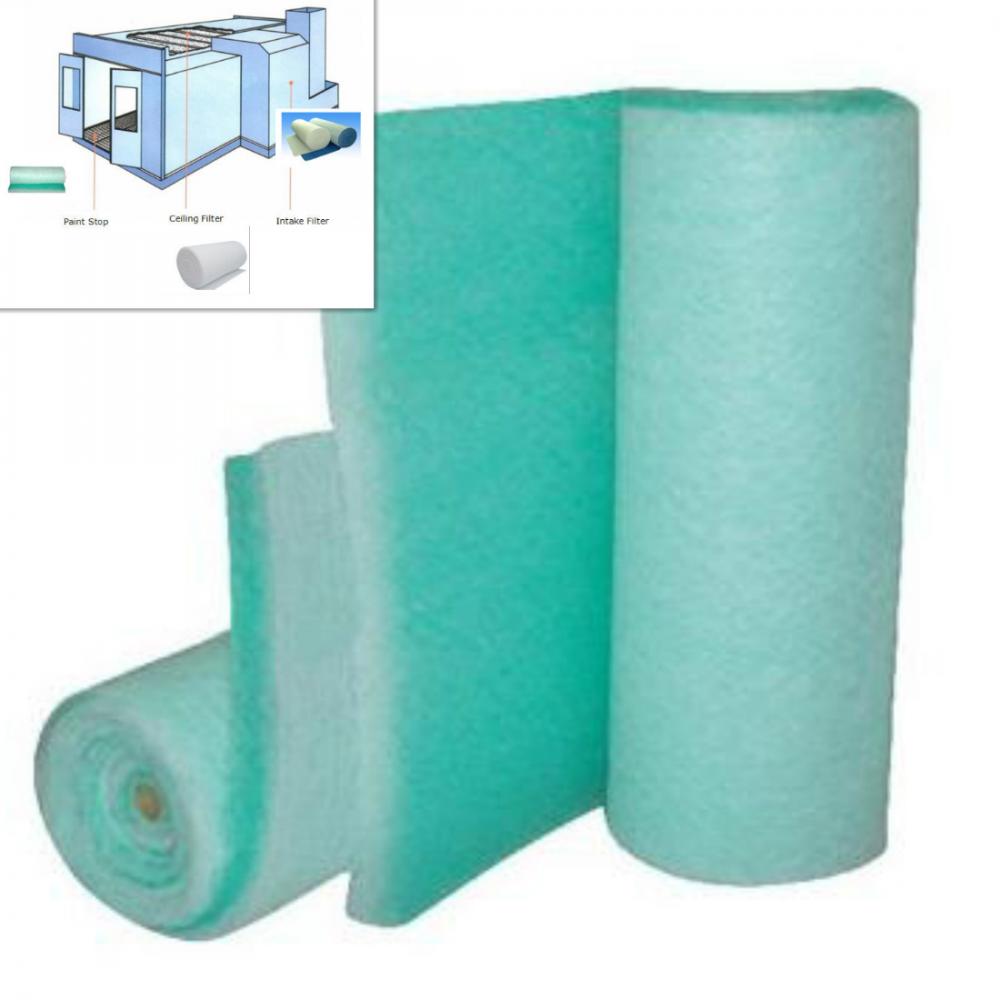

If you run a spray booth, you already know the mess overspray can make—finish quality, duct cleanliness, even insurance audits. That’s why shops keep asking me about paint stop filter media. In the last two years, I’ve watched a quiet shift: more fiberglass arrestors, better progressive density, and a return to simple, reliable roll goods that don’t fight your fan curve.

Product snapshot and specs

Product name: Paint Spray Booth Filter Media (origin: Second Building and Studying No21 Shiji Street, Handan, Hebei, China). It’s classic fiberglass paint stop filter media—thick loft, open face upstream, tighter fibers downstream.

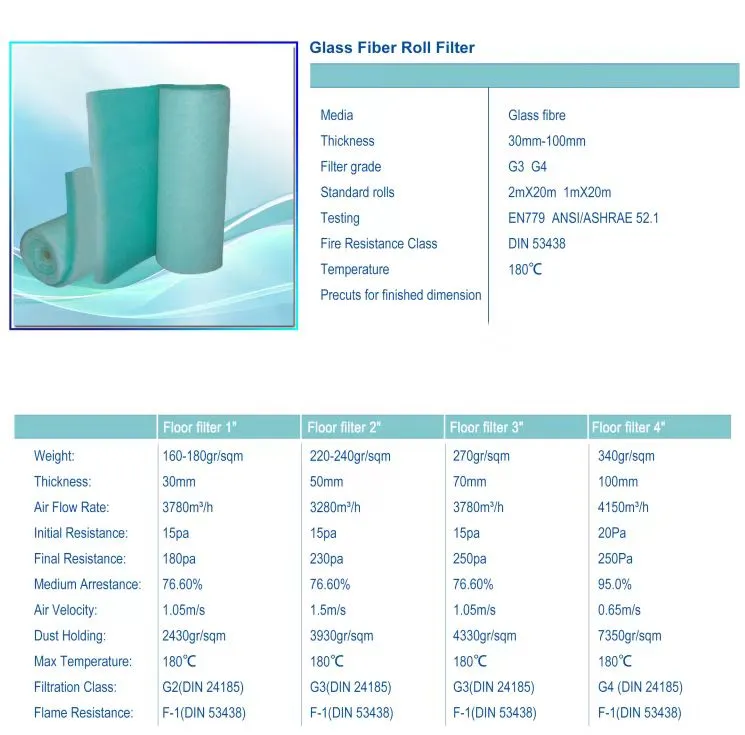

| Media | Glass fiber, progressive density |

| Thickness | 30–100 mm (≈1.2–4.0 in) |

| Filter grade | G3 / G4 (EN 779 legacy; see ISO 16890 note) |

| Standard rolls | 2 m × 20 m; 1 m × 20 m |

| Fire resistance | DIN 53438 (self-extinguishing class as tested) |

| Temperature limit | Up to 180 °C |

| Typical initial resistance | ≈ 15–30 Pa at 0.5 m/s (real-world use may vary) |

| Arrestance (paint mist) | ≈ 93–97% with proper face velocity |

How it’s made and tested

Process flow, briefly: molten glass → micro-fiberization → progressive layering → resin bonding → thermal setting → roll slitting → QC. Methods I’ve seen at the plant include basis-weight checks, thickness gauges, Frazier air-permeability, pressure-drop curves, and DIN 53438 flame tests. Some lots are sampled against ISO 16890 protocols for reference, even though G3/G4 sits in a prefilter zone.

Change-out? Most booths retire paint stop filter media around 250–450 Pa final resistance or on visual loading—whichever comes first. In busy auto refinish, that could be weekly; furniture lines might run longer, depending on solids content and color changes.

Where it’s used (and why)

- Auto refinish and collision booths (prep, prime, topcoat)

- Wood finishing lines—cabinets, doors, furniture

- Metal fabrication paint cells and general industry

- Aerospace touch-up bays (check fire and facility standards)

Advantages people mention: predictable loading, overspray capture without choking fans, and easy roll changes. Some shops pair it with a ceiling prefilter or tackified pad upstream for dust control.

Customization and options

Available as rolls or pre-cut pads; custom widths, cores, and carton counts. Many customers ask for downstream “tack” treatment; it’s optional, depends on paint chemistry. Private-label printing is doable. To be honest, color coding helps crews: green/white orientation is still the easiest training cue.

Vendor landscape (quick comparison)

| Vendor | Media/Grade | Temp/Fire | Lead time | Notes |

|---|---|---|---|---|

| FiltersMaterial (China) | Fiberglass G3–G4 | 180 °C / DIN 53438 | ≈ 7–15 days | Strong OEM/roll options |

| Global Brand X | Fiberglass G3 | ≈ 150 °C / flame-rated | 2–4 weeks | Broad dealer network |

| OEM Converter Y | Tackified fiberglass G4 | ≈ 160 °C / flame-rated | Made-to-order | Custom pad sizes |

Real-world notes, data, and compliance

- Customer feedback: “less bounce-back” on high-solids clear; fewer duct cleanings per quarter. Anecdotal, yes—but consistent.

- Test tidbit: at 0.5–0.7 m/s face velocity, arrestance stayed above ≈95% until near final resistance in our trial. Internal data; conditions vary.

- Standards to mind: ISO 16890 for classification context, DIN 53438 fire behavior, NFPA 33 and OSHA 1910.107 for spray operations and ventilation.

Quick case snapshots

Auto body shop, 2-booth setup: Switched to 50 mm G4 paint stop filter media. Reported 1 fewer duct cleaning per quarter and steadier airflow. Estimated energy drop ≈8% due to longer stable pressure.

Furniture line, waterborne: 100 mm depth with downstream tack. Overspray capture “noticeably better,” color changeovers cleaner; change-out every 2–3 weeks. Customer-reported.

Buying tips

- Match thickness to paint load; thicker media holds more and protects fans.

- Verify flame behavior per DIN 53438 and your local code authority.

- Specify roll width to fit tracks; sloppy fits leak overspray—common, fixable.

- Track pressure weekly; swap pads before finish defects tell you first.

Citations

- ISO 16890-1:2016 Air filters for general ventilation. https://www.iso.org/standard/71955.html

- DIN 53438 Testing of combustible materials; behavior under fire. Overview: https://standards.globalspec.com/std/10010588/din-53438

- NFPA 33 Standard for Spray Application Using Flammable or Combustible Materials. https://www.nfpa.org

- OSHA 1910.107 Spray finishing using flammable and combustible materials. https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.107

- EN 779:2012 (withdrawn) – Particle filters for general ventilation. https://standards.cencenelec.eu

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog