oil-water separation filter paper,automotive filter paper,wood pulp water separator fuel filter paper,wood pulp filter paper is a key solution in the Special Equipment Manufacturing Industry, specifically within Manufacturing of specialized equipment for environmental protection and Industrial filter paper manufacturing. This article explores how Hebei Fangyu Filters Material Technology Co,. Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- oil-water separation filter paper,automotive filter paper,wood pulp water separator fuel filter paper,wood pulp filter paper Overview

- Benefits & Use Cases of oil-water separation filter paper,automotive filter paper,wood pulp water separator fuel filter paper,wood pulp filter paper in Industrial filter paper manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Special Equipment Manufacturing Industry

- Conclusion on oil-water separation filter paper,automotive filter paper,wood pulp water separator fuel filter paper,wood pulp filter paper from Hebei Fangyu Filters Material Technology Co,. Ltd.

oil-water separation filter paper,automotive filter paper,wood pulp water separator fuel filter paper,wood pulp filter paper Overview

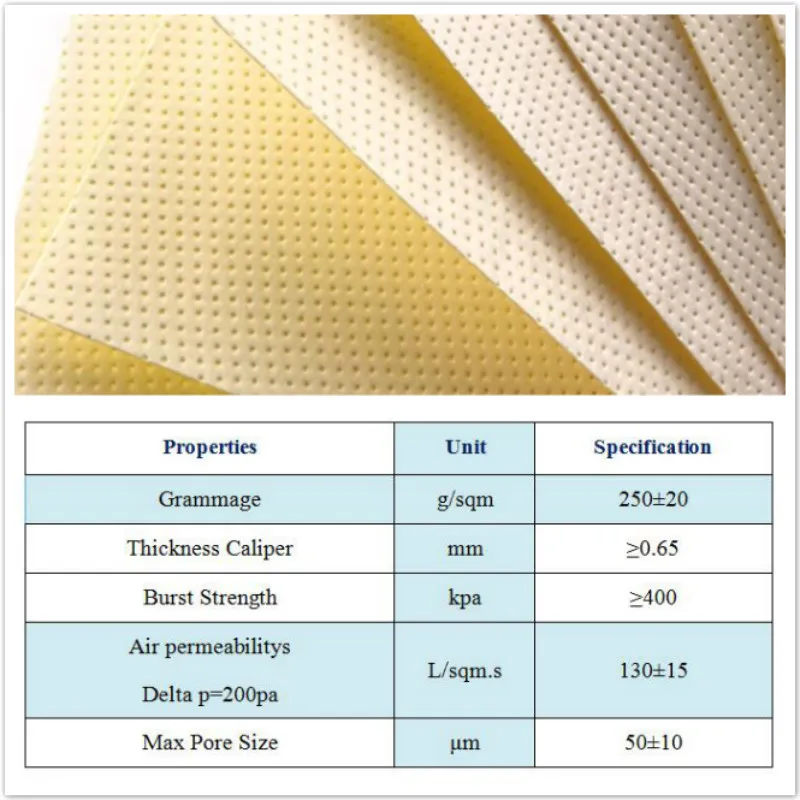

In fuel handling and engine protection, laminated oil-water separation filter paper plays a critical role by coalescing and shedding water from diesel, gasoline, and kerosene streams before they reach sensitive components. Hebei Fangyu Filters Material Technology Co,. Ltd. engineers wood pulp water separator fuel filter paper by combining high-purity cellulose with performance resins and functional surface treatments to drive fast coalescence, high wet strength, and low pressure drop. Typical options include basis weights of 90–220 g/m², thicknesses of 0.30–0.80 mm, controlled pore structures in the ~5–30 μm range, and Frazier air permeabilities tailored to OEM targets. Multi-layer constructions pair hydrophilic coalescing layers with hydrophobic release layers to accelerate droplet growth and drainage. These materials are designed to align with common validation methodologies (e.g., SAE J1488, ISO 16332) while maintaining consistent pleatability and dimensional stability for efficient element production. As a reliable manufacturer in Industrial filter paper manufacturing, Hebei Fangyu offers roll widths, core types, and resin systems customized to B2B program requirements.

Benefits & Use Cases of oil-water separation filter paper,automotive filter paper,wood pulp water separator fuel filter paper,wood pulp filter paper in Industrial filter paper manufacturing

From automotive filter paper for on-engine fuel-water separators to bulk storage and transfer filtration, Fangyu’s wood pulp filter paper solutions support OEMs, tier suppliers, and aftermarket brands. Key applications include diesel engines (on-road/off-road), marine fuel polishing, gensets, construction equipment, and fuel dispensing cabinets. Competitive advantages center on reliable water removal in ULSD and biodiesel blends, high wet burst strength for pleated geometries, uniform resin impregnation for predictable permeability, and coatings that enhance water release while resisting emulsions. Manufacturers benefit from tight caliper control for precise corrugation, consistent resin cure for stable pleat pack formation, and low variation across rolls that reduces scrap during converting. Hebei Fangyu’s technical team collaborates on specification setting—matching grammage, porosity, and surface energy to target separation efficiency and differential pressure curves—helping accelerate validation and shorten time-to-market for new filter element designs.

Cost, Maintenance & User Experience

Total cost of ownership in filtration is driven by service interval length, energy use (pressure drop), and reliability. By selecting the right oil-water separation filter paper, buyers can lower changeout frequency, protect injectors and pumps from corrosion and cavitation, and minimize warranty exposure. Fangyu’s laminated constructions are built for durability under cyclic wetting, maintaining structural integrity in high-flow, high-vibration conditions. For converters, consistent roll-to-roll properties improve line speed and reduce setup waste—translating into tangible savings. End users typically monitor elements via differential pressure; when paired with properly specified coalescing/release layers, customers often observe steadier ΔP rise and predictable maintenance windows, reducing unplanned downtime. Practical tips: store wood pulp water separator fuel filter paper at 20–25°C and 45–55% RH, precondition before pleating, and follow OEM guidelines for housing drain intervals to keep separated water from re-entraining. The outcome is a cleaner fuel system, fewer call-backs, and a clearer ROI path for B2B decision makers.

Sustainability & Market Trends in Special Equipment Manufacturing Industry

Environmental protection equipment is evolving alongside cleaner fuel mandates, biodiesel adoption, and stricter engine emission standards (e.g., Euro/China VI and marine rules). These trends raise the bar for water separation performance as modern fuels can form stable emulsions. Industrial filter paper manufacturing is responding with renewable-fiber content, solvent-conscious impregnation strategies, and designs that extend filter life to reduce waste. Hebei Fangyu Filters Material Technology Co,. Ltd. prioritizes efficient material utilization, consistent quality to limit scrap, and collaborative engineering that right-sizes specifications—avoiding over-engineering that increases resource use. For B2B buyers, this means access to automotive filter paper and wood pulp filter paper options that support sustainability goals without compromising throughput or protection. As the sector grows, expect greater emphasis on traceable supply chains, safer chemistries, and performance verified against recognized test methods to ensure compliance and long-term resilience.

Conclusion on oil-water separation filter paper,automotive filter paper,wood pulp water separator fuel filter paper,wood pulp filter paper from Hebei Fangyu Filters Material Technology Co,. Ltd.

For organizations in the Special Equipment Manufacturing Industry, high-efficiency oil-water separation filter paper is essential to safeguard engines, extend service intervals, and meet environmental objectives. Hebei Fangyu’s automotive filter paper and wood pulp water separator fuel filter paper deliver dependable coalescence, robust wet strength, and converter-friendly consistency—backed by responsive technical support. Ready to optimize your next filter program? Contact us: email: sales@filtersmaterial.com. Visit our website: https://www.filtersmaterial.com. Explore the product page here: laminated filter paper for fuel and water separation.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog