If you spend time around fuel polishing rigs or fleet maintenance shops, you hear the same thing: water is the quiet saboteur. That’s why Oil-water Separation Filter Paper has gone from niche to necessity. The unit I looked at most recently—Laminated Filter Paper Fuel and Water Separation, produced in Second Buliding and Studying No21 shiji street, Handan, Hebei China—uses a layered stack (phenolic paper + melt-blown PBT non-woven laminates) aimed at diesel fuel fine filtration and, crucially, coalescing/separation of water. To be honest, the uptick in biodiesel blends makes this more relevant than ever.

What’s driving demand

ULSD, tighter OEM injector tolerances, and cold-flow challenges, actually. Many customers say they see recurring codes tied to water-in-fuel sensors after rainy weeks. It seems that robust coalescer media is now a baseline feature for fleet fuel systems, marine bunkering, and standby gensets.

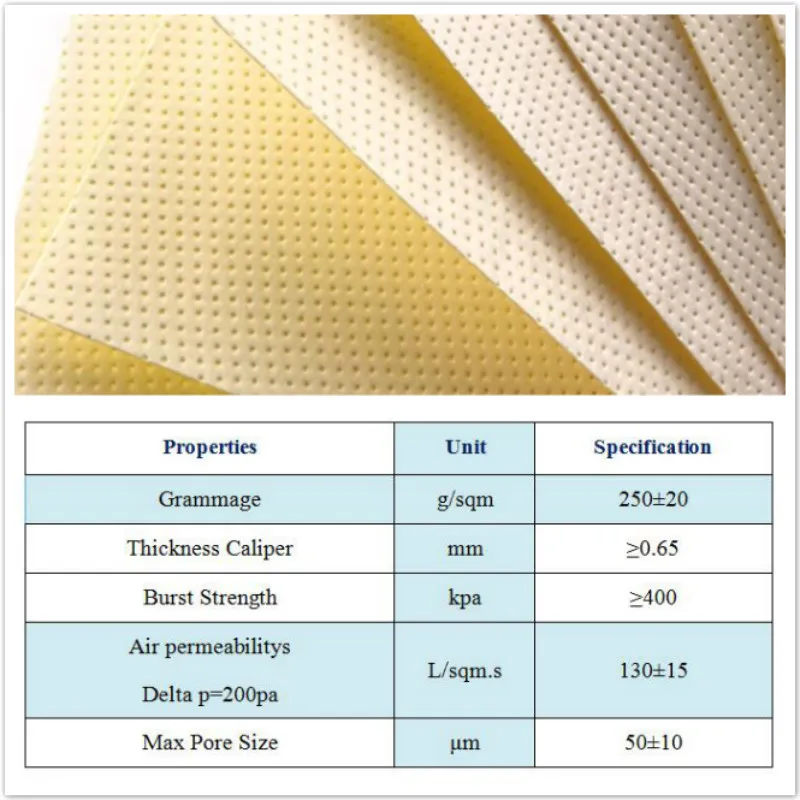

Product specifications (typical)

| Construction | Laminated phenolic-impregnated cellulose + melt-blown PBT non-woven |

| Basis weight | ≈120–200 g/m² (real-world use may vary) |

| Thickness | ≈0.5–1.2 mm |

| Mean flow pore size | ≈8–20 µm (media level) |

| Water separation (SAE J1488) | ≈95–99% free water removal in diesel, depending on fuel chemistry |

| Burst strength | ≈150–300 kPa (media test) |

| Temperature range | -20 to 120 °C (fuel duty) |

| Recommended service life | Up to 6–12 months or ΔP limit; water load dependent |

| Roll width / customization | Up to ≈1000 mm; custom caliper, resin level, and pleatability available |

How it’s made (quick process flow)

- Materials: phenolic-impregnated cellulose base; melt-blown PBT non-woven coalescer layer.

- Methods: resin impregnation → melt-blown fiber laydown → thermal lamination → calendaring → slit/rewind.

- Testing: SAE J1488 water separation; ISO 16889 multi-pass (particle efficiency); ISO 3968 ΔP; ISO 2943 fluid compatibility.

- Service life: driven by water load, fine solids, and differential pressure profile.

- Industries: diesel fleets, marine, gensets, mining, bulk storage polishing.

Where it fits and why it works

Use Oil-water Separation Filter Paper upstream of injectors (or as the coalescer in a duplex housing). Advantages include fast water drop growth, stable pleat geometry, and consistent ΔP. Surprisingly, performance swings with fuel surfactants; always validate on your actual diesel blend.

Vendor snapshot (indicative)

| Vendor | Media construction | SAE J1488 eff. (≈) | Customization | Lead time |

|---|---|---|---|---|

| Filtersmaterial (Handan, China) | Phenolic + melt-blown PBT laminate | 95–99% | Width, caliper, resin level | ≈2–4 weeks |

| Parker Hannifin (media) | Proprietary coalescer stacks | 95–99% | Application-specific | Varies |

| Ahlstrom-Munksjö | Cellulose/synthetic composites | ≈90–99% | Broad portfolio | Varies |

Tip: ask for a J1488 test curve on your actual fuel (with/without FAME and additive pack).

Customization, QA, and field notes

- Customization: pleatability tuning, hydrophobic/hydrophilic balance, and resin level optimization for cold starts.

- Certifications: ISO 9001 QMS; RoHS/REACH statements; Certificate of Analysis per lot.

- Customer feedback: “less water alarms during monsoon season”; “stable ΔP until near end-of-life.”

Mini case studies

- Marine tug fleet: swapped to Oil-water Separation Filter Paper, J1488-validated; free-water discharge dropped ≈70% and injector replacements declined over 2 quarters.

- Mine site gensets: bulk tank polishing added coalescer stage; sight-glass water bottoms fell from daily to weekly drains.

Bottom line: if diesel reliability matters, Oil-water Separation Filter Paper is not just a spec line—it’s cheap insurance against downtime.

- SAE J1488: Fuel/Water Separation Test for Diesel Fuel/Water Separators. SAE International.

- ISO 16889: Hydraulic fluid power—Filter elements—Multi-pass method for evaluation of filtration performance. ISO.

- ISO 2943: Hydraulic fluid power—Filter elements—Verification of material compatibility with fluids. ISO.

- ISO 3968: Hydraulic fluid power—Filters—Evaluation of pressure drop versus flow characteristics. ISO.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog