Official Website

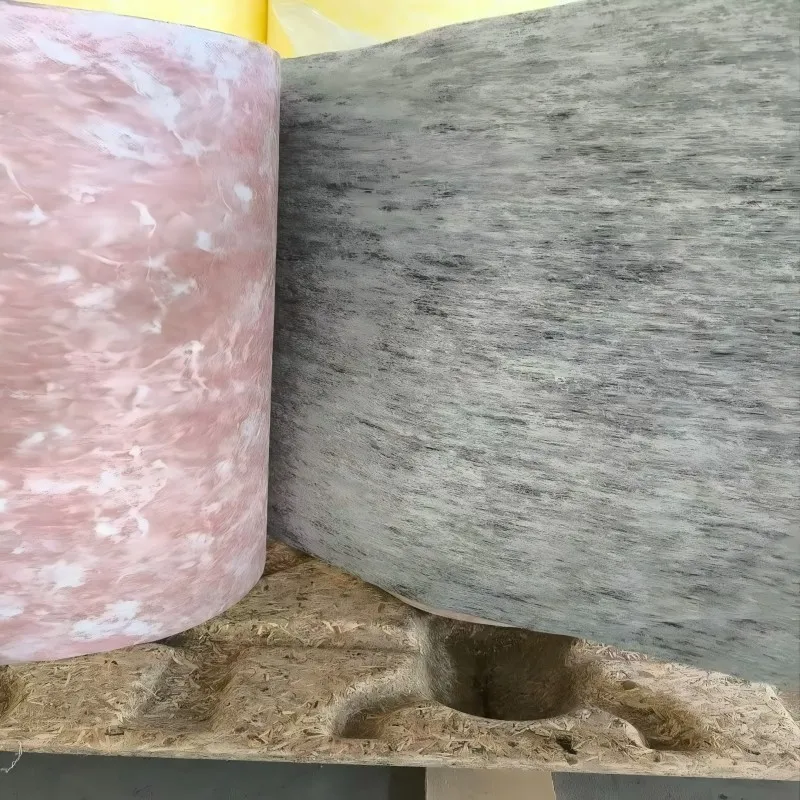

Fiberglass Pocket Filter Media – Product Overview

| Product Name | Fiberglass Pocket Filter Media |

|---|---|

| Technical | Laminated composites, Stitched sewing |

| Media | Ultra fiberglass fiber media |

| Filter Efficiency | F5, F6, F7, F8, F9 (According to EN779) |

| Main Features | Low Resistance, High Efficiency |

| Typical Application | Bag Filters, Panel Filters |

| More Info |

Fiberglass Pocket Filter Media Detailed Page |

Industry Overview: Fiberglass Filter Media

Fiberglass filter media stands at the forefront of modern air filtration technology, being utilized worldwide in HVAC, industrial, commercial, and cleanroom environments. As concerns regarding indoor air quality and particulate contamination grow, the demand for effective and durable filtration solutions such as fiberglass filter media, fiberglass air filter media, and fiberglass filter media rolls has notably increased.

According to leading industry forums and journals such as National Air Filtration Association and Air Filtration News, fiberglass filter media remains central in facilities that require high particulate holding capacity, moisture resistance, and consistent performance over extended service intervals.

Industry Trends

- Shift toward higher MERV-rated fiberglass filter media for enhanced air quality.

- Increased use in pharmaceutical, semiconductor, and food processing sectors.

- Integration of composite technology, such as added carbon layers for odor removal.

- Advances in roll manufacturing for easier large-scale deployment (fiberglass filter media rolls).

- Growing regulations around workplace and cleanroom air quality standards (EN779:2012, ISO16890).

Technical Parameters Comparison Table for Fiberglass Filter Media

| Type | Thickness (mm) | Weight (g/m²) | Initial Resistance (Pa) | Efficiency (EN779) | Max Temp (°C) | Humidity Resistance |

|---|---|---|---|---|---|---|

| Fiberglass Filter Media Rolls | 15-28 | 120-260 | 30-60 | F5-F9 | 250 | ≤100% |

| Fiberglass Air Filter Media | 20-25 | 140-210 | 35-58 | F6-F8 | 250 | ≤100% |

| Fiberglass Filter Material | 12-38 | 90-300 | 28-72 | F5-F9 | 250 | ≤100% |

Application Scenarios of Fiberglass Filter Media

- Commercial HVAC Systems: Office blocks, shopping malls, airports — for particulate, pollen, and fine dust removal.

- Industrial Ventilation: Manufacturing units, paint booths, and sensitive assembly lines, where high particulate holding capacity is critical.

- Cleanrooms: Pharmaceutical, microelectronics, labs — minimizing contamination in ultra-sensitive environments.

- Food & Beverage Industry: Facilities needing both particle and odor/organic vapor filtration.

- Healthcare: Hospitals, clinics for infection control and maintaining air hygiene.

- Pre-filtration: Used as a primary barrier in multi-stage air filtration systems.

Technology Insights: Fiberglass Pocket Filter Media Technical Data Visualization

- Technical Construction: Laminated composite, stitched layers for structural integrity and stable filtration performance.

- Media: Ultra-fine fiberglass fibers maximize microparticle filtration and resistance to chemicals & heat.

- Efficiency: Options from F5 to F9 per EN779, meeting MERV 8-15.

- Pressure Drop: Maintains low initial resistance (30-65 Pa at rated airflow).

- Temperature/Resilience: Up to 250°C, maintains filtration under high humidity.

- Compatible Systems: Bag filters, V-cell, panel filters across varied industry applications.

Advantages of Fiberglass Filter Media Rolls

- Ease of Customization: Allows cutting-to-size for local filter manufacturing and OEM applications.

- Lower Shipping & Storage Costs: Bulk rolls minimize logistic footprint compared to pre-cut panels.

- Consistent Quality: Controlled manufacturing produces uniform fiber alignment and pore structure.

- Long Service Intervals: High dust-holding capacity extends filter life, reducing maintenance frequency.

- Eco-Friendly: Non-toxic, recyclable, with minimal outgassing or VOC emissions.

Expert Q&A: Fiberglass Filter Media Key Technical Terms

Why Choose Hebei Fangyu Filters Material Technology Co,. Ltd. for Fiberglass Filter Media?

- Direct Manufacturer: 12 years of experience, advanced facilities, and in-house R&D.

- Certified Quality: All products meet EN779:2012, ISO16890, CE, SGS & RoHS standards.

- Global Shipping: Door-to-door shipping to over 60 countries, timely delivery.

- Customization: Rolls, panels, and OEM options for global filter producers.

- Technical Support: Expert engineers for filtration design, selection, and troubleshooting.

- One-Stop Service: Bulk orders, samples, after-sales service. Contact us for your fiberglass filter media needs!

References & Industry Sources

-

National Air Filtration Association, “Fiberglass Filtration Media Properties and Applications”

– Read more - Camfil, “EN779 vs ISO16890” – Read more

-

Air Filtration News, “The Impacts of Fiberglass Media in HVAC Filter Performance”

– Read more -

Composites World, “Recycling fiberglass: Novel options available”

– Read more -

Filtration+Separation Journal, “Advances in Glass Fiber Filter Media”

– Read more

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog