The global air filter market is projected to reach USD 24.34 billion by 2030, with a CAGR of 7.4% (source: Grand View Research, 2024). Expanded Metal Mesh for Air Filters is increasingly adopted in air filtration units across petrochemical, metallurgy, and water treatment sectors due to its superior structural integrity, corrosion resistance, and adaptability to high-flow environments.

Growing environmental regulations and the demand for energy-efficient filtration have propelled innovation in mesh design, material quality, and surface coatings. Notably, the shift to customized expanded metal mesh solutions for specialized filtration needs is a strong trend among OEMs and end users.

| Specification | Parameter | Notes |

|---|---|---|

| Mesh Thickness | 0.35 mm – 2.0 mm | Customizable for filter strength |

| Material | Galvanized Steel, Aluminum, SS304/316, Copper | Corrosion resistance varies by alloy |

| Mesh Opening (LW x SW) | 3 x 6 mm to 25 x 50 mm | LW: Long way, SW: Short way |

| Width | Up to 2000 mm | Standard roll or sheet |

| Surface Treatment | Powder Coating, Anodizing, Galvanizing | Enhanced anti-corrosion |

| Open Area Ratio | 30% – 75% | Impacts airflow & dust capture rate |

| Conformity Standards | ISO 9001:2015, ANSI/ASHRAE 52.2, REACH, RoHS | Industrial quality & safety standards |

| Service Life | 8–15 years (avg.) | Depends on environment & maintenance |

ISO 9001 sourcing

Creates diamond-shaped mesh

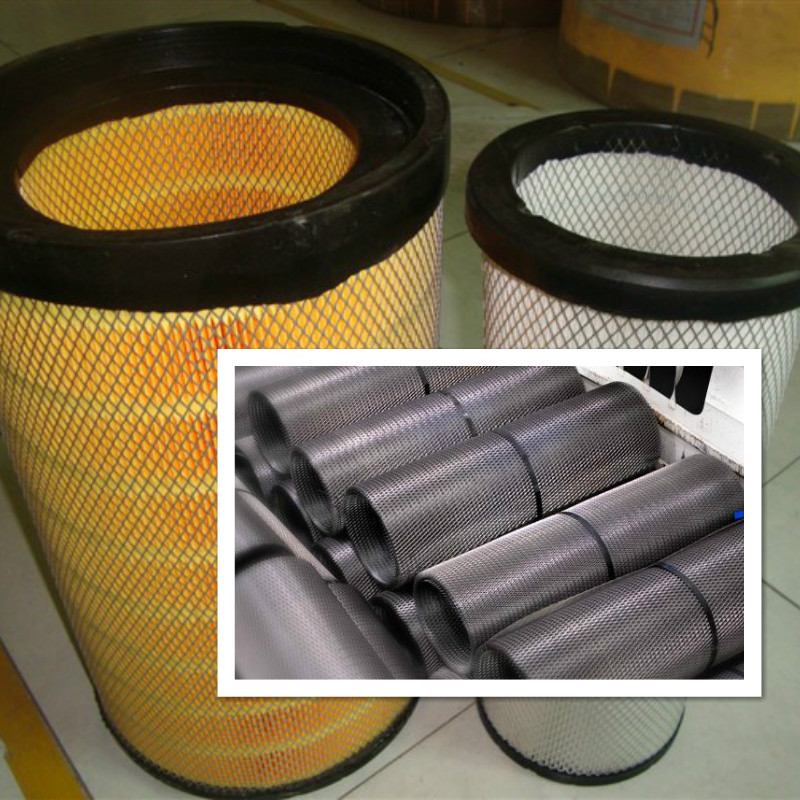

- High Mechanical Strength – Uniform load distribution due to diamond mesh design, preventing deformation under high airflow or particulate load.

- Customized Specifications – Variable mesh size, thickness, and sheet configuration to suit versatile filtration needs, minimizing pressure drop while maximizing capture efficiency.

- Superior Corrosion Resistance – Surface treatments significantly extend operational life, especially in aggressive or humid environments (e.g., chemical plants, offshore platforms).

- Enhanced Energy Efficiency – Open area up to 75% reduces fan load and power consumption, verified by ANSI/ASHRAE 52.2 tests (pressure drop < 45 Pa at 2.5 m/s typical).

- Compliance & Traceability – Documented production batch, ISO 9001:2015 certification, and full RoHS, REACH compliance.

| Supplier | Key Strengths | Certifications | Customization | Global Reach |

|---|---|---|---|---|

| FiltersMaterial | Broad substrate range, premium coatings, fast prototyping | ISO 9001, ANSI/ASHRAE 52.2, REACH, RoHS | YES (Any mesh size, shape & color) | 80+ countries |

| Camfil | Integrated filter solutions, strong R&D | ISO 16890, Eurovent, FDA | Moderate (Standard mesh grading) | 60+ countries |

| AIR-FILTERS.ORG | Cost-efficient mass production | ISO 9001, REACH | NO (Limited by stock) | 50+ countries |

| AIRGUARD | OEM Meshing, technical support | ISO 9001, ANSI/ASHRAE 52.2 | YES | 40+ countries |

As filtration challenges evolve, businesses increasingly require customized Expanded Metal Mesh for Air Filters to match unique performance, installation, and operational constraints.

FiltersMaterial provides end-to-end service: design consultation, prototype sampling within 7 days, batch production, and rigorous third-party inspection. All mesh can be tailored in:

- Mesh opening (3×6 mm up to 25×50 mm diamond)

- Thickness range: 0.35–2.0 mm

- Material: steel (galv./SS304/316), aluminum, copper alloys

- Surface finishing: hot-dip galvanized, powder coated, PASV, anodized

- Sheets, rolls, cut-to-size panels

Delivery: Rapid prototyping within 7 days; standard batch delivery 12–22 days.

Warranty: Product performance guaranteed up to 10 years in most industrial settings (see Expanded Metal Mesh for Air Filters for warranty details).

Problem: Standard pleated air filters faced frequent rupture due to high dust load and humidity.

Solution: Upgraded to Expanded Metal Mesh for Air Filters (galvanized steel, 1.0 mm thickness, 12×25 mm mesh).

Result: Filter structural integrity improved; replacement cycle extended from 9 to 24 months; downtime reduced by 63%.

Feedback: “Performance boost—zero mesh corrosion after 18 months.”–Chief Facilities Engineer

Case 2: Urban HVAC System (Asia, 2022)

Problem: High-pressure loss in primary air filtration, leading to increased power costs.

Solution: Applied Expanded Metal Mesh for Air Filters (anodized aluminum, 0.65 mm thickness, 6×12 mm mesh; open area 71%).

Result: Power consumption dropped 18.5%; filter efficiency stable after 14 months use.

Case 3: Water Treatment Plant (USA, 2023)

Installed: Stainless Steel 316L expanded mesh (0.9 mm, 18×40 mm), immersion tested per ASTM B117, resistance to saline mist and biocides confirmed. Estimated service life: >10 years.

- Product lines certified to ISO 9001:2015, RoHS, and REACH directives

- Global partnerships include top-10 petrochemical and HVAC plant operators

- All procedures and products tested against ANSI/ASHRAE 52.2 and customer-specific criteria

Expanded Metal Mesh for Air Filters—Frequently Asked Technical Questions

- Lead Time: 7 days (prototype); 12–22 days (custom production), global shipping supported

- Quality Guarantee: 5–10 years for anti-corrosion layers; 8–15 years for mechanical integrity (with typical maintenance)

- Customer Support: 24/7 technical online consulting, free post-sale field assessment, and full traceability

- Replacement & Aftermarket: Rapid exchange service for OEMs, volume discounts, and installation guidance via video/remote

— Filtration Engineering Forum, 2023

- Grand View Research: Air Filter Market – Global Industry Analysis

- ASHRAE Journal: Filtration Materials & Test Standards

- Filtration News: Expanded Metal Mesh Air Filters: Materials & Trends

- Material Science & Engineering C: Performance Study: Expanded Metal Mesh

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog