The Critical Role of Paint Stop Filter Media in Industrial Finishing

In high-stakes industrial finishing environments, the integrity of the paint application process is paramount. Effective filtration is not merely a regulatory requirement but a fundamental aspect of achieving superior product quality, ensuring worker safety, and optimizing operational efficiency. At the core of this filtration infrastructure lies advanced paint stop filter media. These specialized filter elements are engineered to capture overspray particles and prevent their recirculation, thereby maintaining a pristine painting environment and protecting downstream equipment. This detailed exploration delves into the technical intricacies, application benefits, and strategic importance of these essential components for B2B stakeholders.

Industry Trends and Market Dynamics

The global industrial finishing market is experiencing significant evolution, driven by stringent environmental regulations, increasing demand for high-quality finishes, and a push towards greater operational efficiency. Key trends influencing the adoption and development of advanced paint arrestor solutions include:

- Environmental Compliance: Stricter VOC (Volatile Organic Compound) emission standards and particulate matter limits necessitate filter media with higher capture efficiency and longer service life, reducing waste and environmental impact.

- Performance Demands: Industries such as automotive, aerospace, and high-end consumer goods require flawless finishes. This drives demand for filters that prevent paint defects like fisheyes and orange peel by meticulously removing overspray.

- Automation and Robotics: The increasing adoption of automated paint lines requires consistent airflow and pressure drop characteristics from filter media to ensure robot precision and prevent system malfunctions.

- Cost-Efficiency: While initial investment is a factor, the long-term cost benefits of extended filter life, reduced maintenance, and fewer reworks due to contamination are increasingly prioritized by businesses.

Analysts project a steady growth in the paint booth filter market, with a CAGR of approximately 5-7% over the next five years, fueled by industrial expansion in emerging economies and continuous technological advancements in filter media. This underscores the strategic importance of selecting optimal filtration solutions.

Manufacturing Process of Paint Stop Filter Media

The production of high-performance paint stop filter media involves a sophisticated process designed to create a fibrous matrix optimized for paint overspray capture. This section details the key stages:

1. Raw Material Selection

- Fiberglass: Often used for its high heat resistance and excellent depth loading capabilities. It’s typically progressive density, meaning finer fibers are layered towards the clean air side.

- Synthetic Fibers: Polyester, polypropylene, or a blend, offering good chemical resistance, uniform fiber distribution, and the ability to be thermally bonded for structural integrity. These are common for applications requiring washable or flame-retardant properties.

- Binding Agents: Resins or thermoplastic binders are used to stabilize the fiber structure, ensuring durability and preventing fiber migration.

2. Manufacturing Processes

- Fiber Preparation: Raw fibers are opened, blended, and carded to create a uniform web. For fiberglass, this involves specific glass-drawing processes.

- Web Formation: The fibrous web is laid down in multiple layers, often using an air-laid or wet-laid process, to achieve the desired thickness and progressive density. Progressive density is crucial for paint arrestors, allowing larger particles to be captured upfront and finer particles deeper in the media, maximizing dust holding capacity and minimizing pressure drop.

- Binding and Curing: A binding agent is applied (e.g., sprayed, impregnated) and then cured through heat (e.g., oven baking) to lock the fibers in place. This gives the media its structural integrity.

- Finishing: The continuous roll of filter media is then trimmed, slit to specified widths, and rolled onto cores or cut into pads and panels. Some media may undergo additional treatments, such as tackifier application (adhesive coating to enhance particle capture) or flame-retardant treatment.

3. Quality Control and Testing Standards

Rigorous testing ensures product reliability and performance. Key standards include:

- ISO 16890 / EN 779: While primarily for HVAC filters, principles of efficiency testing (e.g., initial pressure drop, dust holding capacity) are adapted. For paint arrestors, efficiency is often measured by gravimetric arrestance against specific paint types (e.g., synthetic dust, liquid paint aerosols).

- ASTM D7242 / ASHRAE 52.2: These standards provide methodologies for testing air filter media, including pressure drop and fractional efficiency, crucial for comparing performance.

- UL 900: For flammability ratings, ensuring the media meets safety requirements in industrial environments.

4. Service Life and Target Industries

The service life of paint stop filter media is contingent on paint type, overspray volume, and airflow, typically ranging from a few days to several weeks. These filters are critical in:

- Automotive manufacturing and refinishing

- Aerospace coating facilities

- Furniture and woodworking finishing lines

- Industrial metal fabrication and protective coating

- Plastics and composites painting

Demonstrated Advantages: In these scenarios, the media’s ability to maintain consistent airflow and high capture efficiency directly translates to energy savings (reduced fan power loss due to premature clogging) and corrosion resistance (by preventing paint accumulation on ductwork and fans).

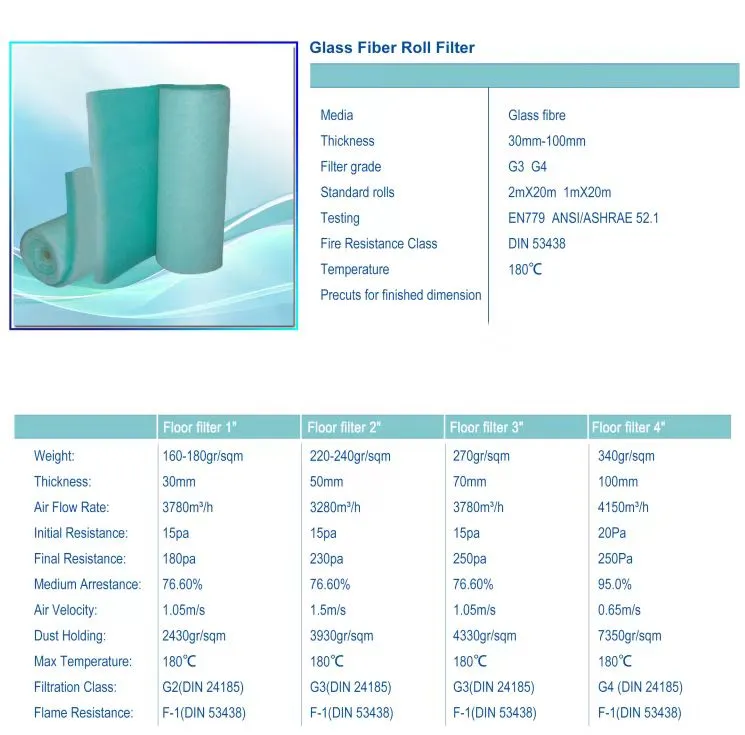

Technical Specifications and Performance Parameters

Understanding the technical specifications of paint stop filter media is crucial for optimal selection and performance in industrial applications. Key parameters include:

- Gravimetric Arrestance: The percentage of test dust (or paint overspray) captured by the filter, typically ranging from 90% to 99%.

- Initial Pressure Drop (Static Pressure): The resistance to airflow across a clean filter. Lower values indicate better energy efficiency. Measured in Pa or in. w.g.

- Dust Holding Capacity (DHC): The total amount of particulate matter a filter can hold before reaching its terminal pressure drop or requiring replacement. Measured in grams.

- Airflow Capacity: The recommended volume of air that can pass through the filter, typically in CFM (Cubic Feet per Minute) or m³/h (Cubic Meters per Hour).

- Filter Media Type: Fiberglass, synthetic (polyester, polypropylene), or a combination, often with a progressive density design.

- Tackifier/Adhesive: Some media are impregnated with a non-drying adhesive to enhance capture efficiency of fine particles.

- Thickness and Density: Affects both dust holding capacity and pressure drop.

Typical Product Specification Table: Paint Arrestor Media

| Parameter | Value/Description | Test Standard |

|---|---|---|

| Media Type | Progressive Density Fiberglass with Tackifier | Visual Inspection |

| Gravimetric Arrestance | ≥ 98.5% | ASTM D7242 |

| Initial Pressure Drop @ 100 FPM (0.5 m/s) | ≤ 0.15 in. w.g. (37 Pa) | ASHRAE 52.2 |

| Dust Holding Capacity (DHC) | ≥ 2500 g/m² | Internal Test Protocol (Simulated Paint) |

| Maximum Airflow Capacity | 300 FPM (1.5 m/s) | Manufacturer Rating |

| Flammability Rating | UL 900 Class 1 | UL 900 |

| Temperature Resistance | Up to 180°C (356°F) | Manufacturer Rating |

| Available Thicknesses | 1″ (25mm), 2″ (50mm), 2.5″ (63mm) | Product Line Data |

Versatile Application Scenarios

The adaptability and effectiveness of paint stop filter media make it indispensable across a multitude of industrial finishing operations. These filters are primarily installed in the exhaust plenum of paint spray booths to capture overspray before it can damage exhaust fans, ductwork, or escape into the environment.

- Automotive Manufacturing and Refinishing: In both OEM (Original Equipment Manufacturer) and aftermarket repair shops, filters are crucial in downdraft, cross-draft, and semi-downdraft spray booths. They ensure a contaminant-free environment for high-gloss finishes and protect expensive exhaust systems.

- Aerospace Industry: Given the stringent quality and safety requirements, aerospace coating facilities rely on highly efficient paint arrestors to manage specialized paints (e.g., anti-corrosion, stealth coatings) and protect the intricate air handling systems.

- Furniture and Wood Finishing: From large-scale furniture production lines to custom cabinetry workshops, these filters prevent wood dust and paint overspray from mixing, maintaining air quality and surface finish.

- Industrial Coating of Metals: For painting heavy machinery, industrial equipment, or structural components, robust paint arrestors are essential to handle high volumes of overspray from various industrial coatings, including epoxies and polyurethanes.

- Plastics and Composites Finishing: Delicate plastic components and advanced composite materials require a clean painting environment to avoid surface defects, making efficient filtration critical.

In each scenario, the correct selection of paint arrestor media, considering factors like paint viscosity, booth configuration, and airflow dynamics, is vital for achieving optimal operational performance and finish quality.

Technical Advantages of Advanced Paint Stop Filter Media

Modern paint stop filter media offers significant technical advantages that translate directly into operational benefits for industrial users:

- High Capture Efficiency: Advanced progressive density designs and tackified media achieve gravimetric arrestance often exceeding 98%, ensuring nearly all overspray particles are captured, preventing environmental release and equipment fouling.

- Optimized Dust Holding Capacity (DHC): Engineered fiber structures maximize the filter’s capacity to hold paint solids without excessive pressure build-up, extending service life and reducing the frequency of filter changes. This directly contributes to lower labor costs and less downtime.

- Low Initial Pressure Drop: Efficient media designs maintain minimal resistance to airflow, which reduces the energy consumption of exhaust fans and blowers, contributing to significant energy savings over time.

- Consistent Performance: High-quality filter media maintains stable capture efficiency and pressure drop characteristics throughout its service life, providing predictable operational conditions and consistent finish quality.

- Robust Construction: Resilient synthetic and fiberglass media, often reinforced, resist tearing and media migration, even under heavy paint loads, ensuring filter integrity.

- Environmental Compliance and Safety: By effectively capturing paint solids, these filters help facilities meet air quality regulations and reduce fire hazards associated with paint accumulation, especially when UL 900 rated.

- Versatility: Available in various thicknesses, densities, and with different tackifier levels, allowing customization for specific paint types (e.g., solvent-based, waterborne, high-solid) and booth configurations.

Vendor Comparison: Choosing the Right Paint Arrestor Supplier

The market for paint arrestor media is competitive, with numerous vendors offering a range of products. Selecting the right supplier and product is critical for operational success. Here’s a comparative overview of factors to consider:

Comparison Table: Advanced Paint Stop Filter Media Solutions

| Feature/Criterion | Standard Fiberglass Media | High-Performance Progressive Density Synthetic Media (e.g., from Filters Material) | Multi-Layered Tackified Media |

|---|---|---|---|

| Primary Material | Loose Fiberglass | Thermally Bonded Polyester/Polypropylene | Fiberglass or Synthetic with Adhesive |

| Gravimetric Arrestance | 85-95% | ≥ 98% | ≥ 99% |

| Initial Pressure Drop | Moderate (e.g., 0.1 in. w.g.) | Low (e.g., 0.08 in. w.g.) | Low-Moderate (e.g., 0.12 in. w.g.) |

| Dust Holding Capacity (DHC) | Good (1500-2000 g/m²) | Excellent (2500-3500 g/m²) | Superior (3000-4000 g/m²) |

| Service Life | Standard (1-2 weeks typical) | Extended (2-4 weeks typical) | Longest (3-6 weeks typical) |

| Cost-Effectiveness | Low initial, higher changeout frequency | Medium initial, lower total operating cost | Higher initial, lowest total operating cost |

| Application Suitability | General purpose, low-volume booths | High-volume, critical finish booths | Finest finishes, challenging paint types |

Beyond product specifications, consider a vendor’s commitment to quality (e.g., ISO 9001 certification), technical support, customization capabilities, and proven track record with reputable clients. Filters Material, for instance, emphasizes rigorous testing and adherence to international standards like ISO and UL to ensure reliability and superior performance for demanding B2B applications.

Customized Solutions for Unique Finishing Challenges

Recognizing that no two industrial finishing operations are exactly alike, leading manufacturers of paint stop filter media offer extensive customization options. This bespoke approach ensures optimal performance, cost-efficiency, and compliance for specific operational parameters. Customization can involve:

- Dimensions and Cut-to-Size: Filters can be tailored to exact booth dimensions, whether in roll form, pads, or panel filters, minimizing waste and ensuring a perfect fit for various spray booth models (e.g., cross-draft, downdraft, side-draft).

- Media Composition: Adjusting the blend of fiberglass and synthetic fibers, or the density and layering, to optimize for specific paint types (e.g., high-solid, waterborne, powder coating overspray) and particle sizes.

- Tackifier Levels: Varying the amount and type of adhesive impregnation to fine-tune particle capture efficiency, particularly for very fine paint mists or challenging paint formulations.

- Progressive Density Configuration: Engineering the filter media with specific fiber densities throughout its depth to maximize dust holding capacity and extend service life under unique paint load conditions.

- Frame Materials: For panel filters, offering various frame options (e.g., cardboard, metal, moisture-resistant) to suit environmental conditions within the booth.

Collaborating with experienced filter engineers allows businesses to conduct site-specific analyses, determine precise filtration requirements, and develop customized solutions that deliver measurable improvements in air quality, finish quality, and operational costs. This partnership approach reflects a commitment to client success and long-term value.

Application Case Studies: Real-World Impact

The tangible benefits of high-quality paint stop filter media are best illustrated through real-world applications. Here are examples showcasing the impact of optimized filtration solutions:

Case Study 1: Automotive OEM Reduces Downtime and Maintenance Costs

A major automotive original equipment manufacturer (OEM) faced challenges with frequent filter changeouts and high maintenance costs due to rapid clogging of their existing paint arrestor filters in a high-volume downdraft paint booth. Overspray from their new waterborne paint system was particularly problematic.

- Solution Implemented: Transitioned to a customized, multi-layered synthetic paint arrestor with a high-capacity tackifier, specifically engineered for waterborne paints and high airflow.

-

Results Achieved:

- Extended filter service life by 45%, reducing changeout frequency by nearly half.

- Decreased annual filter consumption by 30%, leading to substantial material cost savings.

- Reduced labor hours for filter maintenance by 25%.

- Improved air quality within the booth, leading to a 5% reduction in paint defects attributed to airborne contaminants.

Case Study 2: Aerospace Manufacturer Enhances Finish Quality and Compliance

An aerospace component manufacturer required exceptionally clean paint booth conditions for applying specialized coatings, while also needing to meet strict environmental emission standards for particulate matter. Their existing fiberglass filters were struggling with fine particulate capture and had inconsistent performance.

- Solution Implemented: Adopted a high-efficiency, progressive density fiberglass paint arrestor with enhanced media binding and an optimized pore structure. The filters were certified to UL 900 Class 1 for fire safety.

-

Results Achieved:

- Achieved a gravimetric arrestance of over 99%, significantly improving air quality and reducing environmental emissions.

- Maintained a consistent, low pressure drop throughout the filter’s life, ensuring stable booth airflow critical for automated painting.

- Reduced rework rates for critical components by 10%, leading to significant material and labor savings.

- Seamlessly passed environmental audits due to superior particulate capture.

Frequently Asked Questions (FAQ)

Q1: How do I select the right paint stop filter media for my specific paint booth?

A1: Selection depends on several factors: the type of paint used (solvent-based, waterborne, high-solid), the volume of overspray, airflow rates, booth dimensions, and desired finish quality. It’s best to consult with a filter specialist who can recommend media types (fiberglass, synthetic, tackified) and configurations (progressive density, multi-layer) tailored to your exact needs.

Q2: What is the typical service life of paint arrestor filters?

A2: Service life varies significantly based on paint usage, booth operating hours, and the type of media. Standard filters might last 1-2 weeks, while high-capacity, progressive density media can extend to 3-6 weeks. Monitoring pressure drop across the filter is the most reliable indicator for replacement.

Q3: Are these filters environmentally friendly or recyclable?

A3: While the captured paint solids make most paint arrestors non-recyclable in a typical sense, manufacturers are increasingly developing eco-friendly options. Some synthetic media can be incinerated with less harmful emissions, and the overall efficiency of advanced filters reduces total waste volume due to longer service life. Proper disposal should always follow local environmental regulations for hazardous waste.

Lead Time, Fulfillment, and Support

We understand the critical nature of maintaining operational continuity in industrial finishing. Our commitment extends beyond providing high-quality paint arrestor solutions to ensuring reliable logistics and comprehensive customer support.

Lead Time and Fulfillment

- Standard Orders: Typically 3-5 business days for in-stock standard sizes and media types.

- Customized Orders: Depending on complexity and material availability, custom-cut or specialized media may require 7-14 business days. Expedited options are available upon request.

- Global Logistics: We leverage a robust network of logistics partners to ensure timely and secure delivery worldwide, capable of handling both small and large-volume orders.

Warranty Commitments

All our paint stop filter media products are manufactured under strict quality control standards and come with a performance warranty, guaranteeing material integrity and adherence to specified technical parameters. Detailed warranty terms are available upon request and typically cover manufacturing defects and specified performance metrics under normal operating conditions.

Customer Support

- Technical Assistance: Our team of experienced engineers and product specialists is available to provide expert guidance on product selection, installation, and troubleshooting.

- After-Sales Service: We offer comprehensive after-sales support, including performance monitoring advice and recommendations for optimizing filter usage.

- Dedicated Account Management: B2B clients benefit from dedicated account managers who ensure seamless communication and personalized service.

Conclusion

The continuous evolution of industrial finishing processes demands equally advanced filtration solutions. High-performance paint arrestor media stands as a critical component in achieving optimal finish quality, ensuring environmental compliance, and driving operational efficiencies. By understanding the technical specifications, leveraging customized solutions, and partnering with experienced vendors, businesses can significantly enhance their painting operations, reduce costs, and maintain a competitive edge. The strategic investment in superior filtration technology is an investment in product quality, safety, and long-term sustainability.

References

- ISO 16890:2016 – Air filters for general ventilation. International Organization for Standardization.

- ASHRAE Standard 52.2-2017 – Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. ASHRAE.

- ASTM D7242 – Standard Test Method for Static Air Pressure Drop and Filtration Efficiency of Paint Spray Booth Exhaust Filters. ASTM International.

- Underwriters Laboratories Inc. (UL) Standard 900 – Air Filter Units.

- Filtration and Separation Magazine, various issues on industrial air filtration and paint booth technology.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog