Understanding Synthetic Filter Media: A Core Component in Advanced Filtration

In today’s industrialized landscape, efficient and reliable air filtration is paramount for maintaining air quality, protecting sensitive equipment, and ensuring occupational health and safety. At the heart of many high-performance filtration systems lies synthetic filter media. This advanced material, engineered from specialized synthetic fibers, offers superior performance characteristics compared to traditional media, making it indispensable across a vast array of B2B applications. From HVAC systems to cleanroom environments and industrial processing, its role in capturing particulate matter, aerosols, and even micro-organisms is critical.

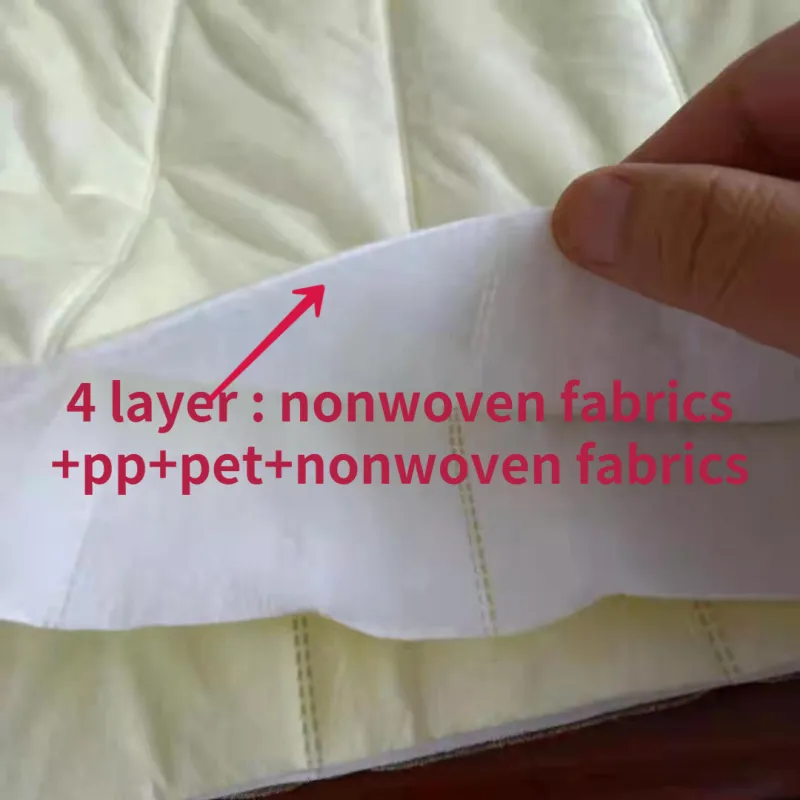

The evolution of filtration technology has been significantly driven by advancements in material science. Traditional filter media often faced limitations in terms of efficiency, dust holding capacity, and resistance to environmental factors. Synthetic alternatives, typically made from polymers like polypropylene, polyester, and acrylic, overcome these challenges by offering engineered fiber structures, hydrophobic properties, and superior mechanical strength. This allows for the development of filters with extended service life, lower pressure drop, and enhanced filtration efficiency, directly translating to energy savings and reduced operational costs for businesses.

Manufacturing Process: Engineering Precision in Synthetic Filter Media Production

The production of synthetic filter media is a sophisticated multi-stage process, demanding precision engineering and rigorous quality control to achieve optimal performance. Unlike simple woven fabrics, these media are often nonwoven structures meticulously designed to maximize surface area and create a tortuous path for particulate capture.

Key Materials

- Polypropylene (PP): Widely used for its excellent chemical resistance, hydrophobic nature, and high filtration efficiency, particularly in meltblown processes.

- Polyester (PET): Offers superior tensile strength, thermal stability, and good resistance to moisture and most chemicals, often used in spunbond or needle-punched constructions.

- Bicomponent Fibers: These fibers feature a core-sheath or side-by-side structure, allowing for thermal bonding at lower temperatures while maintaining structural integrity.

- Specialty Polymers: Including acrylics or PTFE for applications requiring extreme chemical resistance or specific thermal properties.

Manufacturing Processes

The primary methods for creating the nonwoven structure include:

- Meltblown Process: Polymer pellets are melted and extruded through fine dies into high-velocity hot air streams, forming extremely fine, entangled fibers. This creates a dense web with high surface area, ideal for capturing sub-micron particles. Many synthetic air filter media benefit from this process.

- Spunbond Process: Molten polymer is extruded through spinnerets to form continuous filaments, which are then laid randomly on a conveyor belt. These filaments are subsequently bonded, often thermally or mechanically, to create a strong, porous fabric.

- Needle-Punching: While less common for fine filtration media, this mechanical bonding process uses barbed needles to entangle fibers, creating a dense, robust felt.

- Layering and Lamination: Often, different nonwoven layers (e.g., meltblown for efficiency, spunbond for strength) are combined through lamination or calendering to achieve specific performance profiles. This creates composite media with tailored properties, enhancing the performance of synthetic air filter media rolls.

- Electrostatic Charging: Many synthetic media undergo an electrostatic charging process (e.g., corona discharge) post-production. This enhances particle capture efficiency without significantly increasing pressure drop, by attracting oppositely charged particles.

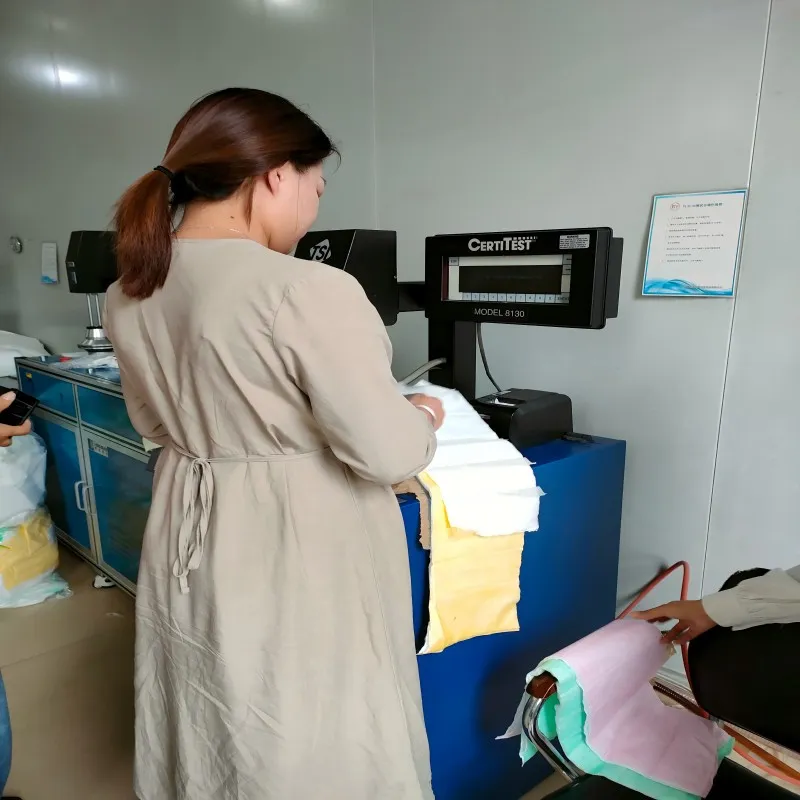

Quality Control and Testing Standards

Throughout the manufacturing process, strict adherence to international standards ensures product reliability and performance:

- ISO 9001: Certifies the quality management system for consistent product delivery.

- ISO 16890: The global standard for evaluating air filter elements for general ventilation, classifying filters based on their ability to capture different particle sizes (e.g., ePM1, ePM2.5, ePM10).

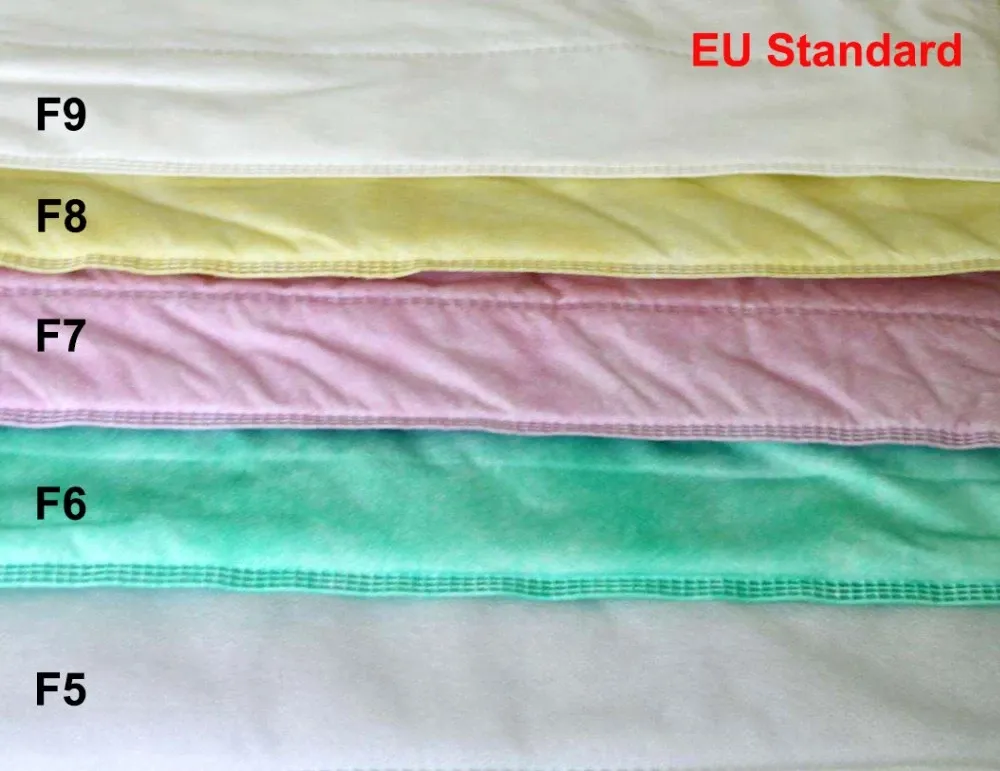

- EN 779: The older European standard for general ventilation filters (F5-F9 grades), still referenced but largely superseded by ISO 16890.

- ASHRAE 52.2: American standard for measuring the performance of air-cleaning devices, using MERV (Minimum Efficiency Reporting Value) ratings.

- Material Composition Analysis: Using techniques like FTIR spectroscopy to verify polymer types and ensure material purity.

- Physical Properties Testing: Including tensile strength, thickness, basis weight, and permeability.

These rigorous processes and testing protocols guarantee that each roll of synthetic filter roll meets the highest industry benchmarks for efficiency, durability, and safety.

Industry Trends and Market Dynamics

The market for synthetic filter media is characterized by continuous innovation driven by increasingly stringent air quality regulations, a heightened focus on energy efficiency, and growing health awareness. Key trends include:

- Higher Efficiency Requirements: A consistent push towards finer particle capture (ePM1 and ePM2.5) to combat the adverse effects of ultrafine particulate matter on human health. This drives demand for advanced meltblown and composite media.

- Sustainability: Increasing interest in media made from recycled content or materials that allow for easier disposal or recycling at end-of-life. Efforts are also focused on developing media with lower pressure drop to reduce energy consumption.

- Antimicrobial and Antiviral Properties: Growing demand for filters incorporating additives or surface treatments to inhibit the growth of bacteria, fungi, and viruses, especially in healthcare and public spaces.

- Smart Filters: Integration of sensors into filter media to monitor dust loading, pressure drop, and remaining service life, enabling predictive maintenance and optimized filter replacement schedules.

- Customization and Specialization: A move away from one-size-fits-all solutions towards highly customized media tailored for specific applications, environmental conditions, and performance metrics.

The global air filtration market is projected to grow significantly, with synthetic media poised to capture a larger share due to its superior performance and adaptability. This growth is particularly evident in regions with rapid industrialization and increasing awareness of indoor air quality.

Technical Specifications and Performance Metrics

The effectiveness of synthetic air filter media is quantified by a range of technical specifications that are critical for engineers and procurement specialists to consider. These parameters define the media’s ability to filter, its durability, and its operational efficiency.

Key Performance Parameters:

- Filtration Efficiency: Measured by ISO 16890 (ePM1, ePM2.5, ePM10) or ASHRAE 52.2 (MERV rating), indicating the percentage of various particle sizes captured.

- Initial Pressure Drop: The resistance to airflow across clean media, a critical factor for energy consumption. Lower pressure drop translates to energy saving.

- Dust Holding Capacity (DHC): The amount of dust a filter can hold before reaching its terminal pressure drop or a specified maximum resistance, directly correlating to service life.

- Basis Weight (g/m²): Indicates the mass of the media per unit area, often correlating with thickness and structural integrity.

- Air Permeability (m³/m²/min @ 200 Pa): The volume of air that can pass through a given area of media under specific pressure conditions, indicating openness of the structure.

- Tensile Strength (N/5cm): Measures the media’s resistance to breaking under tension, crucial for filter durability, especially in applications like synthetic filter roll manufacturing.

- Temperature and Chemical Resistance: Ability to withstand specific operating temperatures and exposure to various chemicals without degradation.

Example Product Specification Table: Synthetic Pocket Filter Media

| Parameter | Value/Range | Test Standard |

|---|---|---|

| Material Composition | Polypropylene/Polyester Bi-component fibers | Internal QC |

| Filter Class (ISO 16890) | ePM1 60% – 85% (F7-F9 equivalent) | ISO 16890-1:2016 |

| Filter Class (ASHRAE 52.2) | MERV 13 – MERV 16 | ASHRAE 52.2-2017 |

| Initial Pressure Drop (at 0.25 m/s) | 30-60 Pa | ISO 16890-3:2017 |

| Dust Holding Capacity | >350 g/m² | ISO 16890-3:2017 |

| Basis Weight | 150-250 g/m² | EN 29073-1 |

| Thickness | 3.0-5.0 mm | ASTM D1777 |

| Max. Operating Temperature | 80°C (176°F) | Manufacturer’s Specification |

| Fire Rating | Class F1 (DIN 53438) | DIN 53438-3 |

Application Scenarios and Target Industries

The versatility and high performance of synthetic filter media make it suitable for a broad spectrum of industries where air quality control is critical. Its robust properties allow it to excel in demanding environments.

Target Industries:

- HVAC & General Ventilation: Used in commercial buildings, data centers, hospitals, and schools to maintain healthy indoor air quality and protect HVAC equipment. This is where synthetic air filter media rolls are frequently converted into finished filters.

- Automotive Manufacturing: Essential for paint booths and assembly areas to prevent particulate contamination, ensuring high-quality finishes and protecting sensitive machinery.

- Pharmaceutical & Healthcare: Critical in cleanrooms, laboratories, and operating theaters for sterile environments, preventing airborne contaminants that could compromise product integrity or patient health.

- Food & Beverage Processing: Ensures hygiene and prevents contamination of food products by filtering air in processing, packaging, and storage areas.

- Electronics Manufacturing: Protects delicate components from microscopic dust particles that can cause defects during production.

- Industrial Facilities (Petrochemical, Metallurgy): Used in processes requiring clean air intake, dust collection systems, and exhaust filtration to meet environmental regulations and protect worker health, offering advantages like corrosion resistance against certain industrial fumes.

- Water Supply & Drainage (Air Stripping/Aeration): While primarily air filtration, media can be adapted for air handling systems used in water treatment to prevent atmospheric contaminants from entering water processing.

Advantages in Typical Application Scenarios:

- Energy Saving: Lower initial pressure drop and slower pressure build-up compared to traditional media means less energy consumed by fans, reducing operational costs significantly.

- Extended Service Life: High dust holding capacity translates to longer intervals between filter changes, reducing maintenance labor and waste.

- Corrosion Resistance: Synthetic polymers are inherently resistant to moisture and many common industrial chemicals, making them suitable for environments where fibrous glass or natural fibers might degrade.

- Consistent Performance: The uniform fiber structure and electrostatic charge (if applied) ensure stable filtration efficiency throughout the filter’s lifespan, even under varying load conditions.

- Moisture Resistance: Hydrophobic properties prevent moisture absorption, which can lead to microbial growth and decreased efficiency in cellulosic or glass media. This is especially beneficial for synthetic air filter media in humid climates.

Technical Advantages Over Traditional Media

The adoption of synthetic filter media stems from its clear technical superiority over conventional filtration materials, particularly in demanding B2B environments. These advantages directly contribute to improved system performance, reduced operating costs, and enhanced environmental compliance.

Key Differentiators:

- Superior Filtration Efficiency: Synthetic fibers can be engineered to be much finer and more uniformly distributed than natural fibers or glass, creating a dense yet open structure that traps a higher percentage of sub-micron particles. Electrostatic charging further enhances this.

- Lower Pressure Drop: Despite higher efficiency, advanced synthetic media are designed to have optimized fiber packing and loft, minimizing airflow resistance. This translates to substantial energy savings for fan systems over the filter’s lifetime.

- Higher Dust Holding Capacity: The structured depth loading capability of synthetic media, especially multi-layered designs, allows them to accumulate significantly more dust before clogging, extending filter service life by 2-3 times compared to some traditional media.

- Hydrophobic Properties: Synthetic polymers like polypropylene are naturally water-repellent. This prevents moisture absorption, which can lead to bacterial and fungal growth, media degradation, and a rapid increase in pressure drop in humid conditions.

- Mechanical Strength and Durability: Synthetic fibers offer superior tensile strength and resistance to shedding. This ensures the filter maintains its integrity, preventing fiber migration into the clean air stream, which is crucial for applications sensitive to contamination.

- Chemical Resistance: Many synthetic materials are highly resistant to acids, bases, and common industrial solvents, making them suitable for diverse industrial exhaust and intake applications where traditional media would quickly corrode.

- Incinerability: Polypropylene and polyester media can often be incinerated safely for disposal, reducing landfill waste volume, a notable advantage over glass fiber filters which can be hazardous.

Comparative Performance Table: Synthetic vs. Glass Fiber Media

| Feature | Synthetic Filter Media (e.g., PP/PET) | Glass Fiber Filter Media |

|---|---|---|

| Fiber Shedding | Minimal to None | Prone to shedding (can contaminate downstream) |

| Moisture Resistance | Excellent (hydrophobic, resists microbial growth) | Poor (absorbs moisture, susceptible to growth) |

| Dust Holding Capacity | High (depth loading structure) | Moderate (surface loading tends to clog faster) |

| Energy Consumption | Lower (due to lower pressure drop) | Higher (due to higher pressure drop) |

| Disposal | Easier (incinerable, non-fibrogenic) | More difficult (fibrogenic, requires special handling) |

| Puncture/Tear Resistance | Good to Excellent | Fair to Poor (brittle) |

Vendor Comparison: Choosing the Right Partner for Synthetic Filter Media

Selecting the right supplier for synthetic filter media is a strategic decision that impacts the performance, cost-efficiency, and reliability of an entire filtration system. When evaluating vendors, several critical factors must be considered beyond just price.

Key Evaluation Criteria:

- Technical Expertise & R&D Capabilities: A leading vendor should demonstrate deep understanding of fiber science, filtration mechanics, and ongoing investment in research and development to produce cutting-edge synthetic air filter media. Look for patents, published research, and a clear product roadmap.

- Product Range & Customization: The ability to offer a diverse portfolio of media types (e.g., meltblown, spunbond, composite, electrostatically charged) and the flexibility to provide customized solutions for unique application requirements.

- Quality Assurance & Certifications: Adherence to international standards like ISO 9001 for quality management and ISO 16890/ASHRAE 52.2 for performance testing. Evidence of independent third-party verification is a strong indicator of reliability.

- Supply Chain Reliability: A robust supply chain ensures consistent material availability, predictable lead times, and the ability to scale production to meet fluctuating demand for synthetic filter roll.

- Customer Support & Technical Service: Comprehensive pre-sales consultation, technical support during implementation, and responsive after-sales service are crucial for long-term partnership.

- Environmental & Sustainability Practices: Vendors committed to sustainable manufacturing, waste reduction, and energy efficiency can align with corporate environmental goals.

- Pricing & Value Proposition: While not the sole factor, a competitive pricing structure coupled with superior product performance and support offers the best overall value.

Our company prides itself on over 15 years of specialization in advanced filtration media. We hold ISO 9001 and ISO 14001 certifications, underscoring our commitment to quality and environmental management. Our media are rigorously tested to ISO 16890 and ASHRAE 52.2 standards, with detailed test data available upon request. We partner with numerous industrial leaders in HVAC, automotive, and pharmaceutical sectors, a testament to our authoritative standing and trustworthiness in the market.

Customized Solutions for Unique Filtration Challenges

Standard synthetic filter media often provides excellent performance, but specific industrial processes or environmental conditions may demand highly tailored solutions. We specialize in developing customized filtration media to address the most intricate challenges faced by our B2B clients.

Our Customization Process:

- Detailed Needs Assessment: Our technical team collaborates closely with clients to understand specific application parameters, including target efficiency, airflow rates, particulate size distribution, chemical exposure, temperature, humidity, and desired service life.

- Material & Structure Optimization: Based on the assessment, we select optimal polymer blends (e.g., specific PP/PET ratios, specialty polymers), adjust fiber diameters, and design multi-layered structures (e.g., graded density) to achieve the required performance balance.

- Additives & Treatments: We can integrate specific additives for enhanced properties, such as antimicrobial agents, flame retardants, or antistatic treatments, directly into the media during manufacturing.

- Prototyping & Testing: Custom media prototypes are manufactured and rigorously tested in our in-house laboratory to ensure they meet all specified criteria, including performance under simulated operational conditions.

- Scalable Production: Once validated, the customized synthetic filter roll design is seamlessly transitioned to full-scale production, maintaining consistent quality and performance across all batches.

Examples of customization include media with enhanced resistance to specific corrosive gases for chemical plants, ultra-low pressure drop media for energy-critical data centers, or media with integrated indicators for filter saturation. This bespoke approach ensures maximum operational efficiency and protection for your critical assets.

Application Case Studies: Synthetic Filter Media in Action

Real-world applications underscore the tangible benefits of deploying high-quality synthetic filter media. These case studies highlight improved performance, cost savings, and enhanced compliance.

Case Study 1: Large-Scale Commercial HVAC System Upgrade

Client: Major office building complex (250,000 sq ft) in a highly polluted urban area.

Challenge: Existing fiberglass panel filters (MERV 8) were insufficient for indoor air quality (IAQ) demands, leading to frequent complaints of dust and allergens. High pressure drop also resulted in excessive energy consumption and filter changes every 3 months.

Solution: Replaced existing filters with high-efficiency synthetic pocket filters utilizing advanced synthetic air filter media (ISO ePM1 70% / MERV 13 equivalent). The hydrophobic properties of the media also addressed moisture issues in the humid mechanical rooms.

Results:

- Improved IAQ: 65% reduction in indoor particulate matter (PM2.5) levels, validated by air quality monitoring.

- Energy Savings: Initial pressure drop reduced by 15%, leading to an estimated 12% reduction in HVAC fan energy consumption.

- Extended Service Life: Filter change intervals extended from 3 to 9 months due to significantly higher dust holding capacity, reducing maintenance costs by 60%.

- Customer Feedback: Tenants reported noticeable improvement in air freshness and a significant decrease in allergy symptoms.

Case Study 2: Precision Manufacturing Cleanroom

Client: Electronics component manufacturer requiring ISO Class 7 cleanroom standards.

Challenge: Previous pre-filters (low-grade synthetic) were shedding fibers and not adequately protecting the expensive HEPA filters downstream, leading to premature HEPA filter replacement and product contamination risks.

Solution: Implemented a multi-stage filtration system using a high-efficiency synthetic filter roll (pre-filter, ISO ePM2.5 75% / MERV 14) that demonstrated zero fiber shedding and superior pre-filtration efficiency.

Results:

- Enhanced Cleanroom Integrity: Maintained consistent ISO Class 7 conditions with reduced particle counts.

- Cost Reduction: Extended the lifespan of HEPA filters by 40%, significantly reducing replacement costs for the most expensive filtration stage.

- Reduced Defects: Noted a 15% decrease in product defects attributed to airborne particulate contamination.

- Operational Reliability: Stable pressure drop profile over the filter’s life ensured consistent airflow and reduced stress on air handling units.

Commitment to Trustworthiness: FAQ, Lead Time, Warranty & Support

Building and maintaining trust with our B2B partners is foundational to our operations. We ensure transparency in our processes, products, and commitments.

Frequently Asked Questions (FAQ)

- Q: What is the typical service life of your synthetic filter media?

A: Service life varies significantly based on application, particulate loading, and airflow. However, our media is engineered for extended durability, often lasting 2-3 times longer than traditional options, translating to 6-12 months in typical HVAC applications.

- Q: Are your synthetic media fire-resistant?

A: Many of our synthetic filter media products are manufactured with inherent flame-retardant properties and tested to standards such as DIN 53438 (Class F1). Specific certifications are available per product line.

- Q: Can your synthetic air filter media rolls be customized for specific dimensions or filtration classes?

A: Absolutely. We offer extensive customization options for width, length, basis weight, and filtration efficiency. Please contact our technical sales team to discuss your specific requirements.

- Q: How does your media contribute to energy savings?

A: Our advanced fiber structures are designed for low initial pressure drop and efficient dust loading, which reduces the energy required by fans to move air through the filter, leading to significant operational energy savings.

Lead Time and Fulfillment

Our standard lead time for stock synthetic filter roll products is typically 2-4 weeks, depending on order volume and specific requirements. For custom orders, lead times will be provided after detailed specifications are confirmed and may range from 4-8 weeks, including prototyping and testing phases. We maintain robust inventory levels and efficient logistics to ensure timely delivery globally.

Warranty Commitments

All our synthetic filter media products are backed by a comprehensive warranty against manufacturing defects and material integrity for a period of 12 months from the date of purchase, or until the filter reaches its recommended terminal pressure drop, whichever comes first. This warranty reflects our confidence in our product quality and adherence to strict production standards.

Customer Support and After-Sales Service

Our commitment extends beyond delivery. We provide dedicated technical support, including assistance with product selection, installation guidance, and troubleshooting. Our experienced engineers are available for remote consultations and on-site visits where necessary to ensure optimal performance of our filtration media in your systems. For any inquiries, our support team can be reached via phone at [Insert Phone Number] or email at [Insert Email Address].

Conclusion

Synthetic filter media stands as a cornerstone of modern, high-performance air filtration. Its engineered properties, superior efficiency, extended service life, and resistance to environmental factors offer unparalleled advantages for B2B applications across diverse industries. By choosing advanced synthetic media, businesses can achieve optimal air quality, significant energy savings, reduced maintenance costs, and enhanced operational reliability, all while meeting stringent regulatory demands. Partnering with an expert vendor who understands these technical nuances and offers comprehensive support ensures that your investment in filtration technology delivers maximum return and long-term value.

References

- International Organization for Standardization. ISO 16890-1:2016, “Air filters for general ventilation – Part 1: Technical specifications, requirements and classification system based on particulate matter efficiency (ePM).”

- American Society of Heating, Refrigerating and Air-Conditioning Engineers. ANSI/ASHRAE Standard 52.2-2017, “Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size.”

- Nonwovens Industry Magazine. “Nonwovens in Filtration: A Market Overview.” [Accessed from industry-specific publications, e.g., nonwovens-industry.com]

- European Committee for Standardization. EN 779:2012, “Particulate air filters for general ventilation – Determination of the filtration performance.”

- Filters Material Official Website. “Synthetic Pocket Filter Media.” filtersmaterial.com/synthetic-pocket-filter-media.html

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog