The Critical Role of Advanced Filtration in Modern Finishing Environments

In industrial painting and finishing operations, achieving a flawless surface finish is paramount. This objective hinges significantly on maintaining an ultra-clean air environment within the spray booth. A cornerstone of this environmental control is the sophisticated design and deployment of high-performance spray booth ceiling filters. These filters are engineered not merely to capture airborne particulates but to deliver a laminar airflow that is free from contaminants, thereby preventing defects such as fisheyes, craters, and dust inclusions on painted surfaces. Their technical excellence directly impacts product quality, operational efficiency, and overall profitability in sectors requiring pristine finishes.

The selection and implementation of the correct filtration media are crucial for optimal performance, extended filter life, and reduced maintenance costs. Our focus encompasses the intricate details of their design, manufacturing, application, and the significant advantages they offer to B2B clients.

Industry Trends and Market Dynamics in Air Filtration

The market for industrial air filtration, particularly for specialized applications like paint booths, is experiencing dynamic shifts driven by several key trends. Increasing regulatory scrutiny over VOC (Volatile Organic Compound) emissions and particulate matter (PM) necessitates more efficient and compliant filtration solutions. Furthermore, the global drive towards sustainability is pushing manufacturers to develop filters with longer service lives, reduced energy consumption (lower pressure drop), and materials that are more environmentally friendly.

Technological advancements include the integration of progressive density filter media, which optimizes dust holding capacity and extends operational intervals. The demand for higher filtration efficiencies, such as those meeting EN 779 F7 standards or ISO 16890 ePM1 > 70%, is rising as industries strive for zero-defect production. Moreover, the prevalence of smart manufacturing and Industry 4.0 paradigms encourages the adoption of filtration systems that offer real-time monitoring and predictive maintenance capabilities, further enhancing efficiency and reliability. The automotive sector, aerospace, and general industrial finishing remain primary drivers, with a growing emphasis on high-quality paint booth ceiling filters that ensure the integrity of critical surface coatings.

The Advanced Manufacturing Process of Spray Booth Ceiling Filters

The production of high-performance spray booth ceiling filters involves a meticulous multi-stage process designed to achieve specific filtration characteristics, durability, and operational consistency. Unlike typical industrial components involving casting or CNC machining, these filters are primarily manufactured through advanced textile and synthetic fiber processing.

Process Flow Overview:

- Material Selection: High-quality, continuous, progressive-density synthetic fibers (typically polyester or polypropylene) are chosen for their resilience, chemical inertness, and ability to be thermo-bonded. Materials are selected to be silicone-free to prevent paint defects.

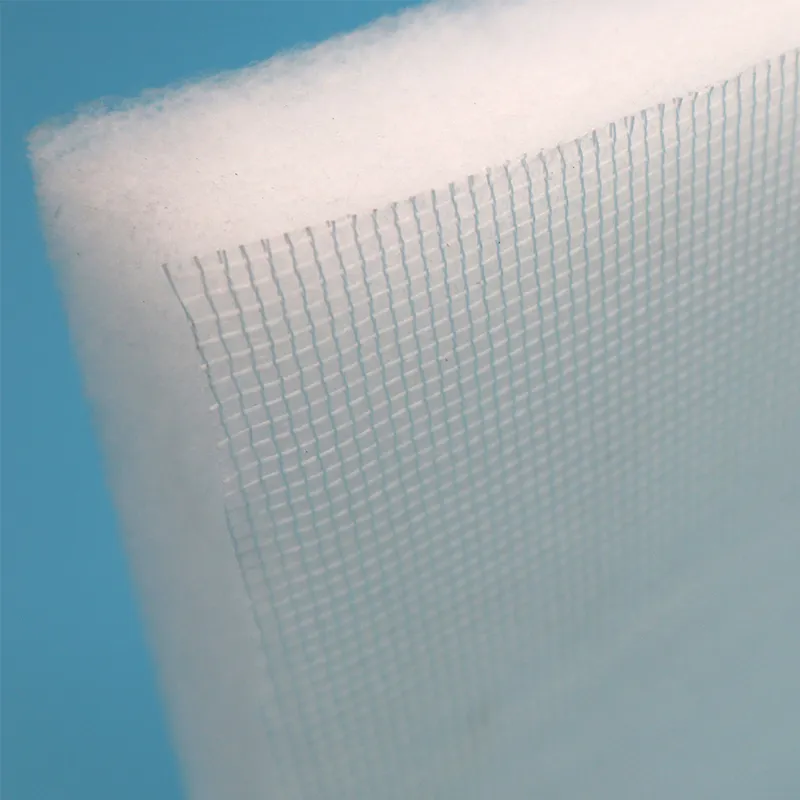

- Fiber Blending and Layering: Fibers are blended and mechanically carded into multiple layers, forming a graduated density structure. This structure ensures that larger particles are captured in the coarser upstream layers, while progressively finer particles are arrested in the denser downstream layers, maximizing dust holding capacity and minimizing pressure drop.

- Thermal Bonding: The layered fiber mat undergoes a thermal bonding process. Heat is applied to partially melt and fuse the synthetic fibers, creating a robust, self-supporting filter medium with consistent porosity and structural integrity. This prevents fiber migration, which could contaminate the paint finish.

- Tackifier Impregnation: The bonded filter media is uniformly impregnated with a specialized, non-migrating adhesive (tackifier). This non-drying resin enhances particle capture efficiency by creating a sticky surface that securely holds captured dust and paint overspray, even during high airflow rates.

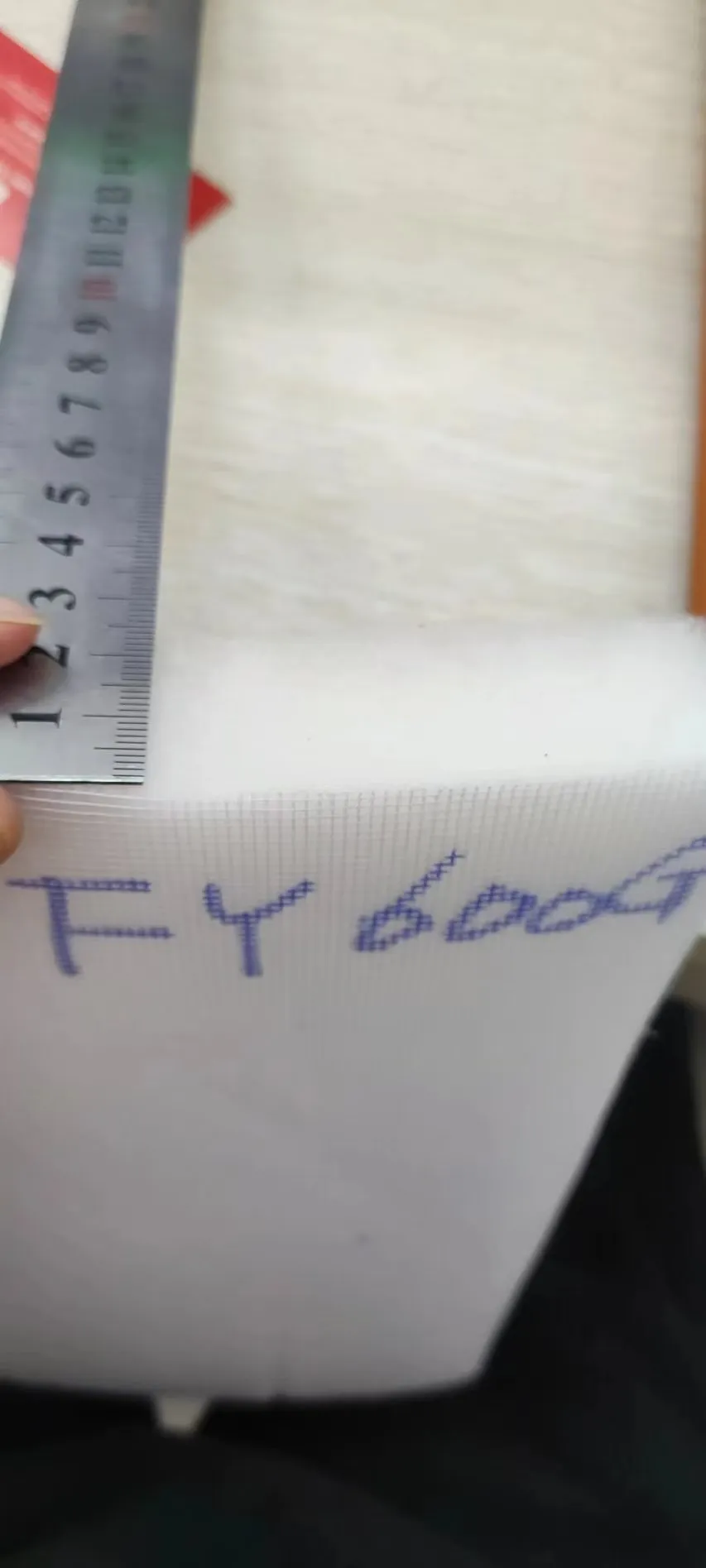

- Scrim Backing Application: A reinforcing scrim backing (often a synthetic mesh or net) is applied to the downstream side of the filter media. This scrim provides additional structural stability, prevents filter sag under load, and ensures an even air distribution pattern across the entire filter surface, which is critical for laminar flow.

- Precision Cutting and Finishing: The finished filter media is precisely cut into standard dimensions (e.g., rolls or panels) using automated cutting equipment to ensure exact fits for various spray booth configurations. Edges are often sealed to prevent bypass.

- Quality Control and Testing: Each batch undergoes rigorous testing against international standards such as EN 779:2012 (for classification like F5, F7) and ISO 16890 (for ePM classification). Tests include initial pressure drop, final pressure drop, dust holding capacity, arrestance, and fractional efficiency. Material integrity and tackifier consistency are also verified.

Target Industries and Advantages:

- Target Industries: Automotive OEM manufacturing, automotive refinishing, aerospace finishing, industrial coating facilities, furniture production, and general metal fabrication requiring high-quality paint application.

- Key Advantages:

- Energy Saving: Optimized progressive density design results in lower initial pressure drop, reducing the energy consumption of HVAC systems and fans, aligning with ISO 50001 energy management principles.

- Superior Particulate Retention: The tackified media and graduated structure effectively capture sub-micron particles, ensuring a particle-free environment crucial for Class A finishes.

- Extended Service Life: High dust holding capacity postpones filter change-outs, minimizing downtime and labor costs.

- Consistent Finish Quality: Prevents paint defects caused by airborne contaminants, leading to fewer reworks and higher customer satisfaction.

- Corrosion Resistance: Materials are designed to be chemically inert and resistant to common paint solvents and chemicals, maintaining integrity in harsh booth environments.

Technical Specifications and Performance Parameters

The performance of spray booth ceiling filters is defined by a range of critical technical parameters that directly impact their effectiveness and suitability for various industrial applications. These parameters are rigorously tested according to international standards to ensure consistent quality and reliable operation.

| Parameter | Description | Typical Value (F5/EU5) | Typical Value (F7/EU7) |

|---|---|---|---|

| Filtration Class (EN 779:2012) | Classification based on average arrestance for synthetic dust. | F5 (Arrestance >95%) | F7 (Average Efficiency >80% for 0.4 µm) |

| Filtration Class (ISO 16890) | New global standard for particulate matter efficiency. | ePM10 > 60% | ePM1 > 70% |

| Initial Pressure Drop | Resistance to airflow at rated capacity when new. | 15-30 Pa | 25-45 Pa |

| Recommended Final Pressure Drop | Pressure drop at which filter replacement is advised. | 250 Pa | 450 Pa |

| Rated Airflow Capacity | Volume of air processed per unit time (e.g., m³/h per m²). | 4000-5000 m³/h/m² | 3000-4000 m³/h/m² |

| Dust Holding Capacity | Total amount of dust a filter can hold before reaching final pressure drop. | 400-600 g/m² | 350-500 g/m² |

| Material Composition | High-performance, progressive density synthetic fibers. | Non-woven Polyester, Tackified | Non-woven Polyester, Tackified |

| Temperature Resistance | Maximum continuous operating temperature. | Up to 80°C (176°F) | Up to 80°C (176°F) |

| Thickness (Nominal) | Physical thickness of the filter media. | 20-25 mm | 22-28 mm |

Note: Specific values may vary based on product design and manufacturer. Consult product datasheets for precise specifications.

Diverse Application Scenarios for Spray Booth Ceiling Filters

The versatility and critical importance of high-quality filtration make paint booth ceiling filters indispensable across a wide array of industrial sectors where precision finishing is a prerequisite. These filters are the final stage of air intake filtration, directly impacting the quality of the painted surface.

- Automotive OEM Manufacturing: In the production lines of leading automotive manufacturers, these filters are crucial for ensuring a perfect, blemish-free finish on vehicle bodies. The stringent quality standards in this industry demand filtration systems capable of removing even microscopic particles that could compromise paint adhesion or aesthetics.

- Automotive Refinishing and Collision Repair: Independent body shops and service centers rely on these filters to achieve factory-like finishes during vehicle repair. Contaminant-free air prevents costly reworks and ensures customer satisfaction, maintaining the vehicle’s aesthetic and resale value.

- Aerospace Industry: For aircraft components, particularly those requiring specialized coatings for corrosion resistance or stealth capabilities, the air quality in paint booths must be impeccable. Spray booth ceiling filters ensure that no particulate matter interferes with these critical applications, adhering to strict aerospace material and process specifications.

- Industrial Coating Facilities: Manufacturers of machinery, heavy equipment, electronics enclosures, and architectural elements depend on these filters for high-quality, durable coatings. The filters protect against environmental dust, enhancing the longevity and appearance of industrial products.

- Furniture Manufacturing: High-end furniture makers, especially those dealing with lacquers, varnishes, and specialized finishes, utilize ceiling filters to prevent dust from settling on freshly coated surfaces, ensuring a smooth, premium finish.

- Plastic and Composite Product Finishing: Industries producing plastic injection molded parts or composite structures for various applications (e.g., medical devices, consumer electronics) require clean environments to apply protective or decorative coatings without defects.

Technical Advantages of Our Spray Booth Ceiling Filters

Our advanced spray booth ceiling filters are designed with a host of technical advantages that translate directly into superior operational performance and cost-effectiveness for our B2B clients:

- Progressive Density Structure: Engineered with layers of varying fiber densities, our filters capture larger particles on the upstream side and progressively finer particles deeper within the media. This design maximizes dust holding capacity, extends filter service life, and maintains a low, stable pressure drop, which is vital for consistent laminar airflow and energy efficiency.

- Optimized Tackifier Impregnation: Each filter media is uniformly saturated with a high-performance, non-migrating tackifier adhesive. This specialized resin actively captures and retains airborne particulates, including microscopic dust and overspray, preventing them from shedding and contaminating the finished product. The tackifier remains stable even under varied temperature and humidity conditions.

- Integrated Scrim Backing: A durable synthetic scrim is thermally bonded to the clean air side of the filter. This scrim provides superior structural integrity, preventing media sag or collapse under high airflow or dust loading. It also helps to uniformly distribute air, ensuring even airflow across the entire ceiling plenum.

- Exceptional Particle Retention: Our filters consistently achieve high filtration efficiencies, typically meeting or exceeding EN 779 F5/F7 or ISO 16890 ePM10 > 60% and ePM1 > 70% standards. This ensures the removal of critical paint-damaging particulates down to sub-micron sizes.

- Low Initial Pressure Drop: The engineered media design provides minimal resistance to airflow when new. This reduces the workload on the spray booth’s fan system, leading to significant energy savings and lower operational costs throughout the filter’s lifespan.

- Silicone-Free Composition: All materials used in our filters are rigorously tested and certified as silicone-free. This is critical in paint applications where silicone contamination can lead to severe paint adhesion issues and surface defects like “fisheyes.”

- High Temperature Resistance: Capable of operating effectively in temperatures up to 80°C, our filters are suitable for booths with heated curing cycles, maintaining their integrity and filtration efficiency under challenging thermal conditions.

- Eco-Friendly Disposal Options: While primarily synthetic, efforts are made in product design to minimize environmental impact where possible, and we provide guidance on responsible disposal methods.

Vendor Comparison: Evaluating Spray Booth Ceiling Filter Providers

Choosing the right supplier for paint booth ceiling filters is a strategic decision that impacts operational efficiency, product quality, and long-term costs. While many vendors offer filtration products, key differentiators exist in product quality, technical support, and customization capabilities. This comparison highlights factors critical for B2B decision-makers.

| Feature/Criteria | Our Offering | Standard Market Offering | Budget-Tier Offering |

|---|---|---|---|

| Filtration Standard Compliance | EN 779:2012 (F5, F7), ISO 16890 certified (ePM10, ePM1) | EN 779:2012 (F5) or older standards | Basic arrestance rating, often non-certified |

| Media Composition | High-grade progressive density synthetic fibers, silicone-free | Synthetic fibers, may not be progressive density or silicone-free | Mixed fibers, inconsistent density, potential silicone content |

| Tackifier Presence/Quality | Uniformly impregnated, non-migrating, high-performance tackifier | Basic tackifier, potentially uneven application or migration | Often untreated or minimal tackifier |

| Structural Integrity (Scrim Backing) | Integrated, thermally bonded scrim for superior stability | Basic scrim or none, prone to sagging | No scrim, high risk of collapse |

| Service Life / Dust Holding Capacity | Extended service life due to high DHC (400-600 g/m²) | Moderate service life (200-400 g/m²) | Short service life (<200 g/m²) |

| Customization Options | Extensive: custom sizes, specific filtration grades, special materials | Limited standard sizes, few grade options | Only off-the-shelf, no customization |

| Technical Support & Expertise | Dedicated engineering support, application guidance, testing data | Basic product information, general support | Minimal or no technical support |

Our commitment to advanced materials, rigorous manufacturing, and adherence to international standards positions us as a premium provider for clients who prioritize uncompromising finish quality and long-term operational value from their filtration systems.

Customized Solutions for Unique Filtration Challenges

Recognizing that no two industrial painting operations are identical, we specialize in providing tailored filtration solutions. Our engineering team collaborates closely with clients to develop custom paint booth ceiling filters that precisely meet their unique operational demands, environmental conditions, and regulatory compliance requirements.

- Non-Standard Dimensions: We offer filters cut to exact specifications, accommodating spray booths of unusual sizes or designs, ensuring a perfect fit and preventing air bypass.

- Specialized Filtration Grades: Beyond standard F5/F7 (EU5/EU7) classifications, we can engineer media for higher efficiencies (e.g., F8, F9) or specific particle size removal, crucial for ultra-sensitive applications in aerospace or medical device coating.

- Advanced Material Compositions: For environments with unique chemical exposures or temperature extremes, we can integrate specialized synthetic fibers, fire-retardant treatments, or anti-static properties into the filter media.

- Optimized Tackifier Formulations: Custom tackifier options are available for specific paint types (e.g., water-based, solvent-based) or particularly challenging particulate types, ensuring optimal adhesion without compromising paint finish.

- Integrated Frame Solutions: We can supply filters pre-mounted in various frame types (e.g., metal, cardboard) for quick installation and compatibility with existing filter housings, streamlining maintenance.

Application Case Studies

Our commitment to tailored solutions is demonstrated through successful deployments:

Case Study 1: Automotive Refinish Shop – Defect Reduction

A large automotive collision repair chain faced persistent issues with paint defects, particularly dust inclusions and minor surface imperfections, leading to a 15% rework rate. Upon consultation, we identified their existing spray booth ceiling filters were of an inconsistent quality and outdated filtration class (EU3/G3 equivalent).

- Solution: We custom-engineered and supplied our F7 (EU7) progressive density filters with enhanced tackifier and a robust scrim backing, cut precisely to their booth specifications.

- Outcome: Within three months, the client reported a dramatic 80% reduction in paint defects attributable to airborne particulates. This led to a 12% decrease in overall rework costs and a significant improvement in customer satisfaction scores, translating to an estimated annual saving of $75,000 across their facilities.

Case Study 2: Aerospace Component Manufacturer – Extended Service Life

An aerospace components manufacturer, applying highly specialized coatings, required frequent filter changes (every 2-3 weeks) due to rapid pressure drop increases, causing significant operational downtime and maintenance expenses. Their existing filters had limited dust holding capacity.

- Solution: We provided a custom version of our F7 filter media, optimized for higher dust holding capacity (600 g/m² vs. 350 g/m²) while maintaining the required ePM1 filtration efficiency, specifically designed to handle the fine, sticky overspray from their specialty paints.

- Outcome: The client experienced a 100% increase in filter service life, extending change-out intervals to 4-6 weeks. This reduced maintenance labor by 50% and decreased annual filter consumption by 40%, resulting in substantial savings and improved production continuity for their critical operations.

Frequently Asked Questions (FAQ)

Q1: How often should spray booth ceiling filters be replaced?

A1: Replacement frequency depends on several factors, including paint volume, type of paint, booth utilization, and ambient air quality. Generally, filters should be replaced when the pressure drop across the filter reaches the manufacturer’s recommended final pressure drop (e.g., 250 Pa for F5) or when paint finish quality begins to degrade. Regular monitoring of pressure gauges is recommended, typically every 2-4 weeks for active booths, but for some facilities, it could be monthly or quarterly.

Q2: What is the significance of the tackifier in ceiling filters?

A2: The tackifier (an adhesive coating) is crucial for enhancing filtration efficiency. It provides a sticky surface that captures and securely retains fine dust and overspray particles that might otherwise pass through the filter media. This prevents particle re-entrainment into the clean airflow, which could lead to paint defects. Our tackifiers are non-migrating, ensuring no adhesive particles transfer to the painted surface.

Q3: Are your filters silicone-free? Why is this important?

A3: Yes, all our paint booth ceiling filters are certified silicone-free. Silicone contamination, even in trace amounts, can severely impact paint adhesion and cause surface imperfections such as “fisheyes” or craters on freshly painted surfaces. Ensuring filters are silicone-free is a critical requirement for high-quality paint finishing processes, particularly in the automotive and aerospace industries.

Q4: What is your typical lead time for orders?

A4: For standard dimensions and common filtration grades, our typical lead time is 5-10 business days from order confirmation. For customized solutions or large-volume orders, lead times may vary and will be communicated clearly during the quotation process. We maintain robust inventory levels of raw materials to expedite production.

Q5: What warranty do you offer on your filters?

A5: We stand by the quality of our products. Our filters are warranted to be free from defects in material and workmanship for a period of 12 months from the date of purchase, assuming proper storage, installation, and operation within specified parameters. This warranty covers manufacturing defects but does not cover normal wear and tear or damage resulting from improper use.

Q6: How do I get technical support or place an order?

A6: Our dedicated customer support team and technical experts are available to assist you. You can reach us via phone at [Insert Phone Number], email at [Insert Email Address], or through the contact form on our website. For specific application advice or to request a quote for spray booth ceiling filters, please provide details of your current setup and requirements.

Authoritative References and Quality Assurance

Our commitment to quality, performance, and customer trust is underpinned by robust internal processes and adherence to international standards. Our manufacturing facilities are ISO 9001:2015 certified, ensuring consistent quality management systems across all operations. Our filters are rigorously tested and certified to comply with leading global filtration standards, including EN 779:2012 for efficiency classification (e.g., F5, F7) and ISO 16890, the new global standard for measuring filter performance against specific particulate matter fractions (ePM1, ePM2.5, ePM10).

We collaborate with reputable third-party testing laboratories to validate our product claims and ensure unbiased performance data. Our extensive experience, accumulated over [X] years in the industry, and long-standing relationships with leading industrial clients across automotive, aerospace, and general finishing sectors attest to our authoritative standing in the specialized air filtration market. We provide comprehensive test reports and technical documentation to support our product specifications.

Citations

- ASHRAE Standard 52.2-2017: Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size.

- European Standard EN 779:2012: Particulate air filters for general ventilation – Determination of the filtration performance.

- ISO 16890:2016: Air filters for general ventilation – Part 1: Technical specifications, requirements and classification system based upon particulate matter efficiency (ePM).

- Environmental Protection Agency (EPA) – Paint Spray Booth Technology Center.

- Journal of Coatings Technology and Research, Volume 17, Issue 5, October 2020: “Impact of Air Filtration Systems on Automotive Paint Finish Quality.”

- ISO 9001:2015: Quality management systems – Requirements.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog