Website: https://www.filtersmaterial.com

Phone: 8615803208513

Mobile: +86 15803208513

Email: yanxiaowang1981@hotmail.com

Address: Second Buliding and Studying No21 shiji street, Handan, Hebei China

- Industry trends and market growth in oil-water separation filter paper

- Technical parameters, performance indicators, and visualized data comparison

- Applications in automotive, industrial, and marine environments

- In-depth product spotlight: Laminated Filter Paper Fuel and Water Separation

- Expert-level FAQ and industry authority references for EEAT optimization

Data shows the share of automotive filter paper, especially those for water/oil separation, has increased steadily in diesel and gasoline engine applications, marine transport, industrial hydraulic systems, and petrochemical processes. By 2024, global demand for advanced oil-water separation filter paper is projected to reach USD 2.6 billion, with further 5-8% CAGR in the next five years.

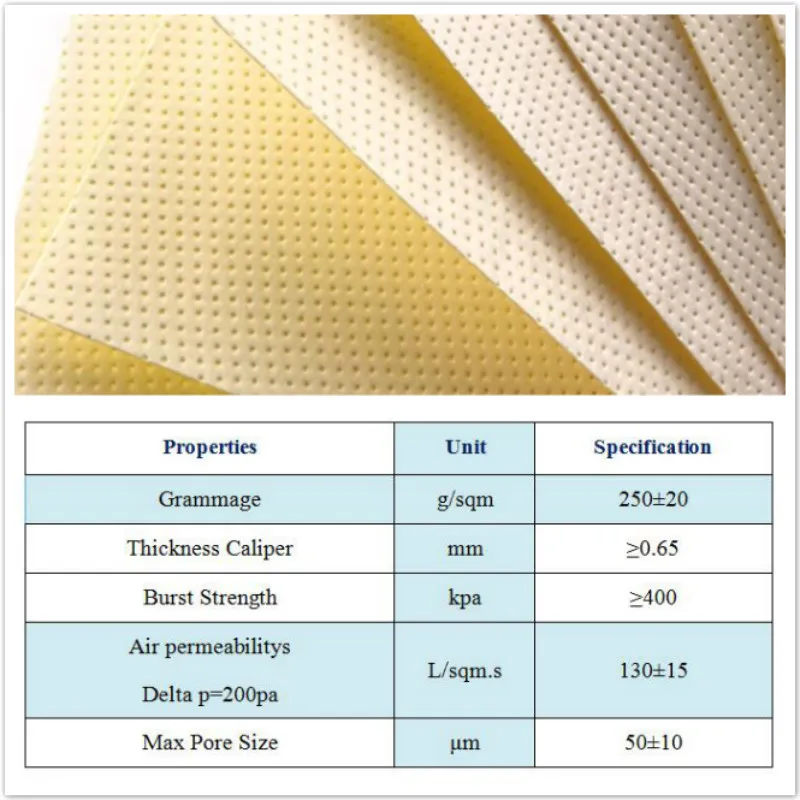

| Parameter | Typical Value | Unit | Industry Standard / Spec | Remarks |

|---|---|---|---|---|

| Material Composition | Phenolic paper / Melt-blown PBT, Wood Pulp, Synthetic Fibers | – | ISO 9001, TS16949 | Preferred for fuel & water separation |

| Separation Efficiency (Water) | 98~99.5% | % | ISO 4020, JIS D1611 | At 10-30 μm particle size |

| Filtration Grade | 5~15 | μm | ISO 16889 | For fine diesel fuel filtration |

| Basis Weight | 140~250 | g/m2 | Customizable | Higher weight for higher efficiency |

| Air Permeability | 65~180 | L/m²/s | GB/T 5453 | At 200 Pa differential pressure |

| Wet Strength | >1.7 | kN/m | GB/T 12914 | Important for fuel filter operation |

| Thickness | 0.36~0.65 | mm | – | Varies by application |

| Max Operating Temp. | 120~175 | ℃ | OEM Spec | Depends on resin and fiber blend |

Material: PHENOLIC PAPER, MELT-BLOWN PBT, NON-WOVEN LAMINATES

Grade: Diesel Fuel Fine Filtration

Application: Fuel Oil/Water Separator Filter Media

View Product Details

- Innovative multi-layer lamination for increased coalescing and demulsification

- Superior performance in high-water-content diesel fuels

- Long-lasting, clog-resistant layers for extended filter life

- Automotive & Heavy Duty Vehicles: Fuel filters for gasoline, diesel, and hybrid vehicles, especially protecting modern high-pressure injection engines.

- Marine Engines: Fuel-water separation in outboard motors, ships, and yachts improves reliability and corrosion resistance.

- Industrial Machinery: Lubrication & hydraulic system maintenance and critical protection of precision pumps.

- Power Generation: Turbine oil circuits and standby generator systems.

- Petrochemical Processing: Downstream filtration, removal of water droplets from product fuels and solvents.

- Agricultural Machinery: High-humidity field environments demand robust filtration to prevent engine damage.

- Coalescence: The filter’s microstructure attracts, captures, and coalesces water droplets from fuel into larger drops, which then migrate out of the filter media.

- Hydrophobic-Hydrophilic Balance: Hydrophilic layers grab water, while hydrophobic surfaces drive rapid ejection—preventing “blinding” and saturation.

- Layered Barrier: Each layer serves a role: initial separation, fine filtration, and final demulsification.

- Extended Service Life: Laminated layers prevent early clogging, with special resins for wet strength ensuring filter integrity even during water shocks or surges.

These advanced properties have led to the oil-water separation filter paper being adopted in premium automotive filters, industrial cartridges, and strict marine-grade fuel separators.

Expert FAQ — Professional Terms for Oil-Water Separation Filter Paper

- Q1: What is the primary material composition of high-efficiency automotive filter paper?

- A: Most premium automotive filter paper for oil-water separation is made from phenolic-impregnated cellulose (wood pulp) blended with synthetic fibers like melt-blown PBT to combine chemical stability, wet strength, and high filtration performance.

- Q2: What does “filtration grade” mean and what grades are ideal for diesel fuel filtration?

- A: Filtration grade refers to the minimum size of particles or droplets a filter can retain. For diesel fuel, grades of 5–15 microns are ideal to capture both fine particulates and water droplets without restricting flow.

- Q3: How is separation efficiency measured and what are typical values?

- A: Oil-water separation efficiency measures the percentage of water removal from fuel. High-end filter media achieve 98–99.5% efficiency at 10–30 μm droplet sizes, tested to industry standards such as ISO 4020.

- Q4: What determines the “wet strength” of filter paper?

- A: Wet strength is the tensile strength the filter maintains when saturated with liquid. Additives, resin impregnation, and fiber blend (especially long-fiber wood pulp) enhance wet strength vital for fuel filters operating in high-water scenarios.

- Q5: Are there set installation standards or best practices for oil-water separation filter cartridges?

- A: Yes, compliance with ISO/TS 16949, OEM vehicle specs, and matching the filter’s flow rate & fit with system demands is crucial. Proper sealing and regular replacement ensure maximized protection.

- Q6: What is the difference between laminated and non-laminated filter papers?

- A: Laminated filter papers, such as those from Hebei Fangyu, fuse multiple layers (hydrophobic/hydrophilic) to optimize both separation and debris filtration, extending lifespan and improving stability versus single-layer papers.

- Q7: How does wood pulp water separator fuel filter paper compare to synthetic-only solutions?

- A: Wood pulp blends offer higher wet strength, biodegradability, and better water coalescence, while pure synthetic materials may provide higher chemical resistance. Laminated designs harness both strengths for optimal performance.

- Advanced R&D and testing laboratories, ensuring every batch meets or exceeds relevant industry standards (Filtration Forum).

- Complete supply chain from wood pulp sourcing to finished oil-water separation filter paper rolls, offering full customization.

- Quick prototyping and OEM services for automotive, marine, and industrial filter brands globally.

- Active participation in global industry conferences and adoption of FiltSep journal best practices (Industry Report).

The oil-water separation filter paper from Fangyu is tailored for each client—balancing separation, flow, chemical resistance, and lifecycle cost.

Phone: 8615803208513 |

Mobile: +86 15803208513

Email: yanxiaowang1981@hotmail.com

Address: Second Buliding and Studying No21 shiji street, Handan, Hebei China

Official website: https://www.filtersmaterial.com

For the latest research and discussion in the filtration industry, see:

– Filtration Forum. “Water Separation Innovations.” forum link

– FiltSep Journal. “Automotive Filtration Trends 2023.” journal link

– SAE Mobilus. “Impact of Filter Media on Fuel Cleanliness.” academic source

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog