Advanced Filtration Solutions: The Strategic Importance of Melt Blown Filter Media

In the demanding landscape of industrial and commercial filtration, the choice of filter media is a critical determinant of system performance, operational efficiency, and overall cost-effectiveness. Among the most versatile and high-performing materials in this sector is melt blown filter media. This sophisticated nonwoven fabric, characterized by its intricate network of microfibers, provides exceptional filtration capabilities, making it indispensable across a spectrum of air and liquid purification applications where stringent contamination control is non-negotiable.

This comprehensive article delves into the foundational aspects and advanced applications of melt blown filtration. We will explore its detailed manufacturing process, crucial technical specifications, expansive application scenarios, and the inherent advantages that position it as a premier choice for B2B decision-makers and engineers. Furthermore, we will address contemporary industry trends, provide guidance on vendor evaluation, highlight the flexibility of customized solutions, and present compelling real-world case studies to underscore its profound industrial impact.

Industry Trends and Market Dynamics for Meltblown Filter Materials

The global market for melt blown filter media is experiencing robust expansion, propelled by an confluence of factors including heightened global awareness of air and water quality, increasingly stringent environmental regulations, and the relentless growth of industries that demand high-performance filtration. Key trends currently shaping this dynamic market landscape include:

- Escalating Demand for Ultra-High Efficiency: There is a continuous technological imperative driving the development of filter media capable of capturing ever-smaller particulate matter with superior efficiency. This is particularly critical in specialized applications such as cleanrooms, pharmaceutical manufacturing, and advanced HVAC systems, fostering innovation in fiber morphology and electrostatic charge enhancement techniques.

- Sustainability and Eco-Consciousness: An increasing emphasis on environmentally responsible solutions is prompting research and development into sustainable polymers, biodegradable alternatives, and filter media engineered for extended service life to minimize waste generation and environmental footprint.

- Advanced Composite Media Development: A significant trend involves the integration of meltblown layers with various other synthetic nonwovens, such as spunbond for structural reinforcement or activated carbon for chemical adsorption. This results in sophisticated composite filter media, exemplified by products like “Meltblown And Synthetic Composite Filter Media,” offering multi-functional benefits including improved mechanical strength, enhanced chemical resistance, and superior dust holding capacity.

- Integration of Smart Filtration Technologies: The emergence of smart filtration systems incorporating sensors for real-time performance monitoring, predictive maintenance analytics, and intelligent operational optimization is transforming the filtration sector, further increasing the value and necessity of high-quality meltblown components.

- Dominance of Asia-Pacific Market: The Asia-Pacific region continues to be a primary growth engine, driven by rapid industrialization, urbanization, a burgeoning middle class, and rising health consciousness, all contributing to an escalating demand for both air and liquid filtration solutions.

These overarching trends underscore a highly dynamic market where technological agility, robust research and development, and a keen responsiveness to evolving environmental and industrial mandates are paramount for success among melt blown filter manufacturers.

The Advanced Manufacturing Process of Melt Blown Filter Media

The production of high-performance meltblown filter material is a testament to precision engineering, utilizing a thermoplastic extrusion process to generate exceptionally fine microfibers. While polypropylene (PP) remains the primary polymer due to its excellent processability and cost-efficiency, other polymers like polyethylene terephthalate (PET) or polybutylene terephthalate (PBT) are employed for specialized applications requiring enhanced thermal or chemical resistance. The resultant unique fibrous structure—characterized by randomly oriented, self-bonded fibers—is the fundamental basis for meltblown media’s superior filtration capabilities.

Detailed Process Flow:

1. Polymer Resin Preparation

High-quality polymer pellets are meticulously selected based on the desired end-product specifications, including crucial parameters like melt flow rate and molecular weight. These prepared pellets are then precisely metered into the extruder’s feeding system.

2. Extrusion and Melting

Within the extruder, the polymer pellets are heated to their molten state and homogenized. This viscous melt is then uniformly pushed through a specialized die head, which features an array of hundreds or thousands of precision-machined orifices, forming continuous molten polymer filaments.

3. Meltblowing (Fiber Attenuation)

Upon exiting the die orifices, the nascent molten filaments are immediately subjected to converging high-velocity, heated air streams. This powerful air flow rapidly attenuates and stretches the fibers to extremely fine diameters, typically ranging from 1 to 5 micrometers, while they are still in a semi-molten, pliable state.

4. Fiber Collection and Web Formation

The attenuated, cooled fibers are then pneumatically blown onto a continuously moving collection screen or conveyor belt. Here, they randomly intertwine and, due to residual heat, thermally self-bond at their crossover points, forming a cohesive, nonwoven web. This web constitutes the base meltblown filter material.

5. Post-Treatment and Composite Lamination

For “Meltblown And Synthetic Composite Filter Media,” the meltblown web often undergoes further processing. This typically involves combining it with other functional layers, such as spunbond for enhanced mechanical strength, activated carbon for odor and volatile organic compound (VOC) removal, or specialized barrier coatings. Lamination is achieved through thermal bonding, ultrasonic welding, or other precise methods.

6. Winding, Slitting, and Quality Assurance

The final engineered filter media is meticulously wound onto master rolls. These rolls undergo comprehensive quality inspections, including basis weight, thickness, air permeability, and filtration efficiency testing, before being precisely slit into specified widths and lengths for diverse client applications.

Throughout this rigorous manufacturing process, stringent quality control measures are implemented, adhering to international testing standards:

- ISO 2942: Determination of fabrication integrity and first bubble point for liquid filter elements.

- ISO 16890: A global air filter test standard that assesses filtration efficiency for specific particulate matter sizes (e.g., PM1, PM2.5, PM10), critical for evaluating air quality.

- ASTM F2100: Standard specification for performance of materials used in medical face masks, crucial for healthcare applications.

- ASTM D5034: Standard test method for breaking strength and elongation of textile fabrics (grab test), ensuring mechanical integrity.

The typical service life of meltblown media is highly variable, influenced by factors such as particle loading, airflow rates, and environmental conditions. It generally spans from 3 months in heavy industrial applications to over 2 years in less demanding settings. This media inherently offers significant energy savings due to its ability to maintain low pressure drops while achieving superior filtration efficiency, coupled with excellent corrosion resistance stemming from the chemical inertness of polymers like polypropylene.

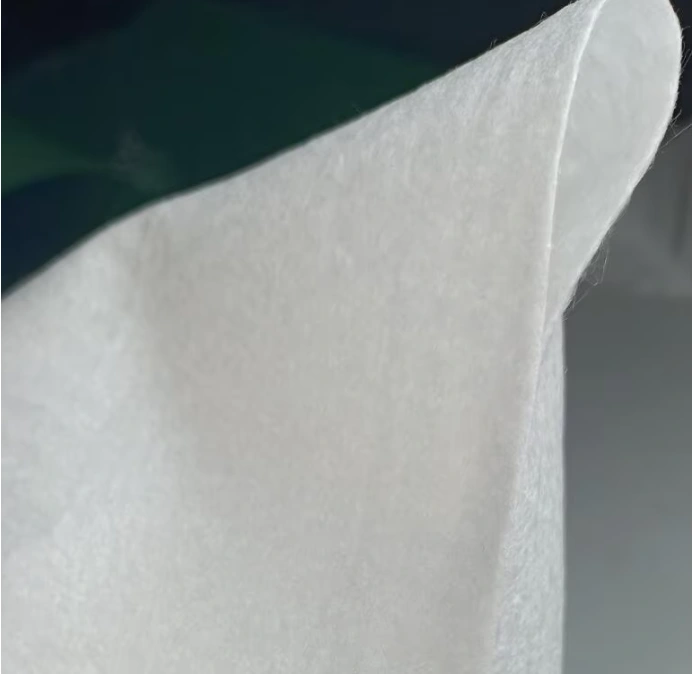

Figure 1: Microscopic view illustrating the intricate fiber structure of melt blown filter media.

Technical Specifications and Performance Parameters

The efficacy and suitability of meltblown media are quantitatively defined by a series of critical technical parameters. A thorough understanding of these specifications is fundamental for engineers and procurement specialists to select the most appropriate media for specific operational requirements.

Key Performance Indicators (KPIs) for Meltblown Filter Media:

Note: Specific values for these parameters are highly dependent on the polymer type, precise manufacturing parameters, and the intended application of the meltblown filter material.

Distinct Advantages and Operational Benefits of Melt Blown Filter Media

The unique structural and material properties of meltblown media translate into a compelling array of operational advantages across diverse industrial and commercial filtration applications.

- Superior Filtration Efficiency: The extremely fine fiber diameter and the dense, tortuous, and randomly oriented web structure of meltblown media create an highly effective barrier against particulate matter. This enables the capture of sub-micron particles (ranging from 0.3 to 10 µm) through a combination of mechanical interception, impaction, diffusion, and often, electrostatic attraction. This capability is paramount for achieving HEPA or ULPA air purity levels.

- Optimized Low Pressure Drop: Despite its high filtration efficiency, advanced meltblown designs are engineered to maintain a remarkably low initial pressure drop. This characteristic directly translates into significantly reduced energy consumption for system fans and pumps, leading to substantial operational cost savings over the filter’s operational lifespan.

- High Dust Holding Capacity (DHC): The inherently high porosity and intricate void network within meltblown media provide an expansive internal volume for particulate accumulation. This allows for a significant dust loading before the filter reaches its terminal pressure drop, consequently extending the filter’s service life and reducing the frequency of costly replacements and associated labor.

- Robust Chemical Resistance: Polypropylene, the most common polymer used in meltblown production, exhibits excellent resistance to a broad spectrum of acids, bases, and many organic solvents. This inherent chemical inertness makes meltblown media highly suitable for use in aggressive chemical environments, particularly prevalent in petrochemical, chemical processing, and industrial wastewater treatment applications.

- Hydrophobicity and Oleophobicity Options: Many meltblown materials can be engineered or treated to impart hydrophobic (water-repellent) or oleophobic (oil-repellent) properties. This is a critical advantage in applications involving moisture-laden air streams, mist elimination, or the separation of oil from water.

- Exceptional Versatility and Customization: The meltblowing manufacturing process offers precise control over key parameters such as fiber diameter, basis weight, and overall media density. This flexibility enables the creation of highly customized media tailored to specific particle size removal targets, flow rates, and pressure drop requirements. Furthermore, the development of composite structures, such as “Meltblown And Synthetic Composite Filter Media,” significantly expands this versatility by combining the high efficiency of meltblown with the structural integrity or additional functionalities of other layers.

- Thermal Stability: Depending on the base polymer selected, meltblown media can withstand a variety of operational temperatures. Polypropylene-based media typically performs reliably up to 80-90°C, while other polymers can offer even higher thermal resistance for specialized high-temperature industrial processes.

These intrinsic advantages collectively position meltblown media as a preferred and often indispensable choice for critical filtration tasks where uncompromising performance, long-term durability, and optimized cost-efficiency are paramount for operational success.

Diverse Application Scenarios Across Key Industries

The exceptional versatility and high performance characteristics of meltblown filter material make it an indispensable component across a broad spectrum of industrial and commercial sectors. Its ability to provide fine particle filtration in both air and liquid streams allows it to address critical needs in various demanding environments.

- HVAC and Advanced Air Purification Systems: Meltblown media forms the core filtration layer in commercial, industrial, and residential HVAC systems, as well as in standalone air purifiers and automotive cabin air filters. It efficiently captures airborne contaminants such as allergens, dust, pollen, fine particulate matter (PM2.5, PM10), bacteria, and viruses. This is crucial for maintaining superior indoor air quality and protecting sensitive equipment from environmental particulate.

- Medical and Healthcare Sector: Extensively utilized in critical medical applications including surgical face masks (meeting N95/KN95 standards), respirators, surgical drapes, isolation gowns, and sterilization wraps. It provides an effective barrier against airborne microorganisms and fluid penetration, essential for infection control and patient safety. The “Meltblown And Synthetic Composite Filter Media” is particularly valued here for its enhanced barrier properties and structural integrity.

- Water and Wastewater Treatment: Employed in various stages of liquid filtration, including pre-filtration, cartridge filters for membrane protection, and sediment removal. It ensures the production of clean process water for industrial use, safeguards sensitive downstream equipment, and aids in meeting stringent discharge regulations.

- Oil & Gas and Petrochemical Industries: Critical for removing contaminants from fuels, lubricants, hydraulic oils, and process chemicals. This application protects high-value machinery from wear and corrosion, ensures product purity, and maintains the integrity of complex chemical processes. Its inherent chemical and corrosion resistance is a significant advantage in these harsh operational environments.

- Food and Beverage Processing: Utilized in clarification processes, sterile air filtration for packaging lines, and water purification systems to meet rigorous hygiene and quality assurance standards. It prevents microbial contamination and ensures product consistency.

- Electronics and Controlled Cleanroom Environments: An integral component of HEPA and ULPA filters, meltblown media is vital for maintaining ultra-clean air conditions in semiconductor manufacturing, precision electronics assembly, and pharmaceutical production. It effectively prevents particulate contamination that could compromise delicate products and processes.

Figure 2: Meltblown media integrated into an automotive cabin air filter, highlighting its application in personal vehicle air purification.

Vendor Comparison: Strategic Selection of Melt Blown Filter Manufacturers

The strategic selection of a reliable partner from the many melt blown filter manufacturers is a pivotal decision for any organization. It directly impacts product quality, supply chain resilience, and the level of technical support available. Below is a structured comparison framework to assist decision-makers in their evaluation process:

Key Criteria for Comprehensive Vendor Evaluation:

A strategic partnership with a reputable and experienced manufacturer ensures access to cutting-edge technology, consistent quality, and responsive technical support, all of which are paramount for optimizing your critical filtration systems and achieving sustained operational excellence.

Customized Melt Blown Filter Media Solutions

Acknowledging that the complexities of industrial filtration often demand unique solutions, leading melt blown filter manufacturers provide extensive customization capabilities. This flexibility is a critical factor in optimizing filtration performance for highly specialized applications and achieving specific operational goals.

Customization options can encompass a wide array of parameters, allowing for precise engineering of the filter media:

- Adjusted Basis Weight and Thickness: These properties can be precisely engineered to control the media’s density, directly influencing both its filtration efficiency and its dust holding capacity. Thicker media can significantly enhance DHC, while denser configurations can improve initial filtration efficiency.

- Optimized Fiber Diameter and Pore Size Distribution: Fine-tuning the meltblowing process allows for meticulous control over the average fiber diameter, which in turn dictates the mean flow pore size. This enables the production of media with specific filtration ratings, critical for capturing precise ranges of particulate matter, from fine dust to specific bacterial sizes.

- Electrostatic Charging Enhancements: The application of a controlled electrostatic charge to the meltblown fibers can dramatically enhance filtration efficiency for sub-micron particles without a proportional increase in pressure drop. This is a common and highly effective customization for advanced air filtration applications.

- Sophisticated Composite Layering: The development of “Meltblown And Synthetic Composite Filter Media” involves strategically laminating meltblown layers with complementary materials. Examples include spunbond for structural rigidity, activated carbon for the adsorption of odors and volatile organic compounds (VOCs), or specialized glass fiber layers for high-temperature resistance, allowing for multi-functional media designs.

- Specialized Surface Coatings and Treatments: Specific surface treatments can impart enhanced functionalities such as hydrophobicity (water-repellency), oleophobicity (oil-repellency), antimicrobial properties, or flame-retardancy. These treatments are vital for optimizing media performance in particularly challenging environmental conditions.

- Tailored Roll Dimensions and Precision Slitting: Media can be supplied in custom roll widths and specific lengths, ensuring seamless integration into client manufacturing processes, minimizing material waste, and optimizing conversion efficiency for filter manufacturers.

Engaging in close collaboration with a manufacturer’s dedicated R&D team empowers clients to develop bespoke filtration solutions that precisely align with their unique operational parameters and performance targets. This tailored approach often leads to significantly superior filtration outcomes and confers a distinct competitive advantage in their respective markets.

Application Case Studies: Quantifiable Impact of Meltblown Filter Media

Case Study 1: Elevated Air Purity in a Semiconductor Fabrication Plant

A major semiconductor manufacturer encountered persistent challenges in maintaining the ultra-low particulate counts required for ISO Class 5 cleanroom environments. Existing filtration systems were struggling with sub-micron particle removal, leading to unacceptably high defect rates on sensitive microchips.

- Solution: The facility upgraded its HEPA filters to incorporate advanced ULPA-grade “Meltblown And Synthetic Composite Filter Media.” This media, specifically designed for ultra-fine particle capture and with enhanced structural stability, was integrated into their recirculating air systems.

- Results: Post-implementation, the cleanroom consistently maintained ISO Class 5 air quality, with particle counts (0.1µm to 0.5µm) reduced by over 99.999%. This led to a dramatic 40% reduction in manufacturing defect rates directly attributable to particulate contamination, resulting in significant yield improvements and millions in annual savings.

Case Study 2: Optimized Filtration in a Large-Scale Petrochemical Processing Facility

A petrochemical plant specializing in polymer production faced issues with catalyst contamination in their process streams, leading to reduced product quality and frequent downtime for system cleaning. Their existing filtration media exhibited insufficient chemical resistance and premature clogging.

- Solution: Implemented specialized meltblown filter material cartridges, manufactured from a chemically resistant polymer (e.g., PBT) and optimized for high-viscosity fluid filtration. These cartridges offered a precise 1-micron absolute rating and superior resistance to the aggressive organic solvents in the process stream.

- Results: Catalyst contamination was virtually eliminated, leading to a 20% improvement in final polymer product purity. Filter service life increased by 75% compared to previous media, significantly reducing maintenance intervals and operational costs by approximately 12% annually, along with a 15% reduction in unplanned downtime.

Case Study 3: Enhanced Efficiency and Longevity in Industrial Paint Booth Ventilation

An automotive paint shop struggled with high filter replacement costs and inconsistent air quality in its spray booths, directly impacting paint finish quality and worker safety. Conventional filters quickly loaded with paint overspray and fine particulate.

- Solution: Installed two-stage filtration systems featuring robust, high-DHC meltblown media for pre-filtration, followed by a finer meltblown layer. The media was designed with a graduated density structure to maximize dust holding capacity for paint particulate while maintaining low pressure drop.

- Results: The overall filter life was extended by an impressive 110%, drastically reducing procurement and labor costs associated with filter changes. Air quality within the booths improved, leading to a 10% reduction in paint finish defects and enhanced compliance with OSHA air quality standards for respirable particulates.

Figure 3: A pleated filter cartridge showcasing the integration of Meltblown And Synthetic Composite Filter Media for optimized performance.

Trustworthiness, Warranty, and Dedicated Customer Support

As a recognized leader in advanced filtration materials, our commitment extends far beyond the mere supply of Meltblown And Synthetic Composite Filter Media. We are dedicated to building enduring, trustworthy partnerships underpinned by transparency, quality assurance, and unparalleled customer service.

- Authoritative Certifications and Industry Recognition: Our state-of-the-art manufacturing facilities and comprehensive product lines rigorously adhere to, and often exceed, stringent international quality management standards, including ISO 9001:2015. Where pertinent, our products are engineered to comply with FDA food contact regulations, REACH, and RoHS directives, demonstrating our unwavering commitment to safety, environmental stewardship, and ethical sourcing. Our active participation in industry associations and strategic collaborations with leading research institutions further solidify our authoritative standing in the field of advanced filtration.

- Decades of Specialized Expertise: With over two decades of focused specialization in the development and production of advanced filtration materials, our team of highly skilled material scientists, process engineers, and application specialists possesses unparalleled expertise. This extensive experience enables us to consistently innovate and optimize meltblown filter material for even the most complex and demanding industrial applications.

- Comprehensive Warranty Commitments: We stand unequivocally behind the superior quality and specified performance of our filtration products. All our meltblown filter media is backed by a robust standard warranty against manufacturing defects and guarantees that critical performance parameters will be met under normal operating conditions. Detailed warranty terms and conditions are transparently provided with each product quotation and can be further tailored to accommodate specific requirements for long-term supply agreements.

- Efficient Lead Time and Reliable Fulfillment: We leverage substantial production capacities and a highly optimized global supply chain to ensure efficient and reliable order fulfillment. Typical lead times for our standard product offerings generally range from 2 to 4 weeks. For urgent requirements, expedited production and shipping options are available. Custom-engineered solutions may necessitate a slightly longer lead time, which is always clearly communicated and agreed upon during the initial project consultation phase. Our strategic inventory management of raw materials and finished goods ensures high service levels and minimizes potential disruptions.

- Dedicated and Responsive Customer Support: Our team of expert customer support representatives and technical specialists is available to assist you Monday through Friday, from 9:00 AM to 5:00 PM (GMT+8), via multiple communication channels including phone, email, and live chat. We provide comprehensive technical assistance, detailed product selection guidance, proactive troubleshooting support, and responsive post-sales service to ensure your complete satisfaction and the optimal performance of your filtration systems.

Frequently Asked Questions (FAQ) about Melt Blown Filter Media

Q1: What is the fundamental definition and primary characteristic of meltblown filter material?

A1: Meltblown filter material is a specialized nonwoven fabric manufactured by extruding molten polymer through a multi-orifice die into high-velocity streams of hot air. This process attenuates the polymer into extremely fine microfibers, which are then collected on a screen to form a dense, randomly oriented, and self-bonded filtration web. Its primary characteristic is an exceptionally small pore size and a high surface area-to-volume ratio, making it highly effective for fine particle capture.

Q2: How does Meltblown And Synthetic Composite Filter Media offer superior performance compared to pure meltblown media?

A2: While pure meltblown excels in its intrinsic filtration efficiency, “Meltblown And Synthetic Composite Filter Media” leverages a synergistic design. It combines the high-efficiency meltblown layer with other synthetic materials (e.g., spunbond for structural rigidity, activated carbon for chemical adsorption) through lamination. This composite structure provides enhanced mechanical strength, greater pleatability, superior dust holding capacity, and sometimes additional functionalities like odor removal, all while maintaining or even improving the meltblown layer’s core filtration efficiency.

Q3: What range of filtration efficiency levels can be practically achieved with meltblown media for industrial applications?

A3: Meltblown media is highly adaptable and can achieve a broad spectrum of filtration efficiencies. For general HVAC applications, it commonly provides MERV 11 to MERV 17 ratings. For more critical requirements, electrostatically charged or highly optimized meltblown media can achieve HEPA (H13/H14, typically >99.97% retention at 0.3µm) and even ULPA (>99.999% retention at 0.12µm) levels, making it suitable for cleanroom and medical applications.

Q4: Is it feasible to clean and reuse meltblown filters to extend their service life?

A4: Generally, standard meltblown filter media is engineered for single-use applications and is designed to be replaced once its dust holding capacity is exhausted or the pressure drop becomes excessive. Attempting to clean these filters, particularly through washing or aggressive agitation, can irrevocably compromise the delicate fiber structure and, if present, any electrostatic charge, thereby significantly degrading filtration efficiency. While some highly robust composite filters incorporating meltblown layers might permit limited cleaning under specific protocols, this is typically not recommended for the meltblown component itself.

Q5: Which polymers are most commonly utilized in the production of meltblown media, and why?

A5: The most prevalent polymer employed in meltblown filter media production is polypropylene (PP). This is primarily due to its excellent processability characteristics, inherent chemical resistance to a wide range of substances, and its cost-effectiveness, making it a highly versatile choice. For specialized applications demanding higher temperature resistance, unique mechanical properties, or specific chemical compatibility, other polymers such as polyethylene terephthalate (PET), polybutylene terephthalate (PBT), and certain polyamides may also be utilized.

Conclusion: The Indispensable Role of Melt Blown Filter Media

The burgeoning demand for high-performance filtration solutions continues to escalate across virtually every industrial and commercial sector globally. At the vanguard of this evolution stands meltblown filter media. Its unique micro-fiber structure, coupled with the inherent capability for advanced composite layering, provides an unparalleled combination of high filtration efficiency, exceptional dust holding capacity, and profound versatility. Whether addressing critical air purification requirements in sensitive healthcare environments, ensuring process integrity in demanding petrochemical operations, or enhancing overall air quality in commercial and residential spaces, meltblown technology consistently delivers robust, cost-effective, and energy-efficient solutions.

By developing a deep understanding of the intricate manufacturing processes, key technical parameters, and expansive application potential of this advanced material, industries can strategically leverage the full power of Meltblown And Synthetic Composite Filter Media. This enables them to not only meet but often exceed stringent regulatory requirements, significantly reduce operational expenditures, and effectively safeguard both valuable personnel and sensitive equipment. Cultivating a strong partnership with experienced and reputable melt blown filter manufacturers who are committed to continuous innovation and uncompromising quality assurance is paramount for unlocking these myriad benefits and achieving sustained success in the complex world of industrial filtration.

Authoritative References

- “Meltblown Nonwovens: A Review of the Manufacturing Process, Properties, and Applications.” ScienceDirect.

- “Handbook of Nonwovens.” Woodhead Publishing.

- “ISO 16890 – Air filters for general ventilation.” International Organization for Standardization.

- “ASTM F2100 – Standard Specification for Performance of Materials Used in Medical Face Masks.” ASTM International.

- “Filtration and Separation Magazine.” Elsevier B.V.

- “Textile Research Journal.” SAGE Publications.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog