The Pivotal Role of Air Filter Media in Modern Industries

In today’s industrialized world, the quality of air directly impacts operational efficiency, product integrity, and human health. At the heart of effective air purification systems lies the filter media – a critical component that determines the filtration efficiency, lifespan, and overall performance of air filters. From protecting sensitive electronics in data centers to ensuring clean breathing air in medical facilities, advanced filter media solutions are indispensable. This comprehensive guide delves into the intricate world of filter media, exploring its technological evolution, diverse applications, and the rigorous standards that govern its excellence, with a specific focus on high-performance materials like Laminated Air Filter Media With Mesh.

The global air filtration market continues to expand, driven by increasing awareness of air pollution and stringent regulatory mandates. Projections indicate a market size exceeding USD 25 billion by 2027, with significant growth in segments demanding high-efficiency particulate air (HEPA) and ultra-low penetration air (ULPA) filtration. This growth underscores the critical need for innovative and reliable filter media solutions that can address complex filtration challenges across various sectors.

Understanding Laminated Air Filter Media With Mesh

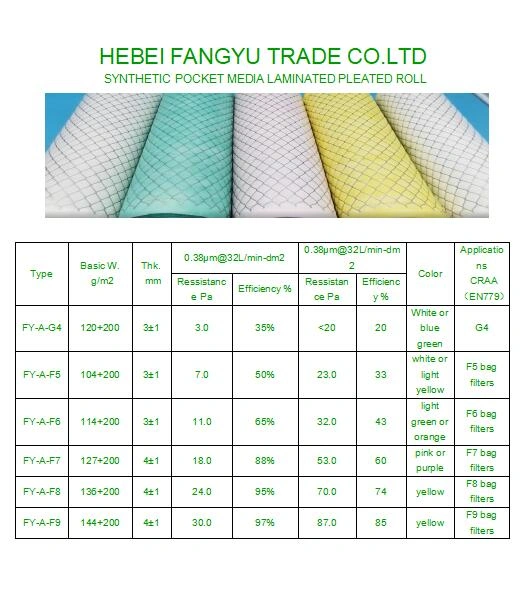

Our flagship product, Laminated Air Filter Media With Mesh, represents a leap forward in air filtration technology. This specialized media combines multiple layers of filtration material, often including a robust synthetic nonwoven fabric reinforced with an integrated mesh layer. The mesh provides structural integrity, prevents media sag, and enhances durability, particularly in high-airflow or demanding environments. This innovative design optimizes dust holding capacity and extends service life while maintaining a low pressure drop.

Typically categorized within the G3 to F9 efficiency range (according to EN 779/ISO 16890 standards), our Laminated Air Filter Media With Mesh is ideal for pre-filtration and fine filtration stages in HVAC systems, industrial ventilation, and other critical air handling units. Its synthetic composition ensures excellent resistance to moisture and microbial growth, making it a reliable choice for diverse operational climates.

Manufacturing Excellence: The Core Process of Advanced Filter Media

The production of high-quality filter media is a complex process demanding precision and adherence to strict quality controls. Unlike metal components that might undergo casting or CNC machining, filter media manufacturing involves sophisticated textile and nonwoven technologies.

Typical Manufacturing Process for Nonwoven Synthetic Filter Media:

- Raw Material Selection: High-grade synthetic fibers such as polyester, polypropylene, and occasionally specialty blends are chosen for their intrinsic filtration properties, thermal stability, and chemical resistance. For specific applications like activated carbon air filter media, activated carbon granules or fibers are integrated at this stage.

- Fiber Processing (Web Formation): Fibers are processed into a uniform web using techniques like:

- Melt-blown: Polymer is extruded through small nozzles into high-velocity hot air, forming very fine, randomly oriented fibers that create a dense web. This is crucial for hepa filter media.

- Spunbond: Continuous filaments are extruded and laid onto a conveyor belt in a random manner, then bonded.

- Wet-laid: Fibers are suspended in water and then deposited onto a screen, similar to papermaking, for very uniform media.

- Web Consolidation (Bonding): The loose fiber web is bonded to give it strength and integrity. Common methods include:

- Thermal Bonding: Fibers are heated to their softening point, allowing them to self-bond at crossover points.

- Chemical Bonding: Application of binders (adhesives) to hold the fibers together.

- Needle Punching: Mechanical interlocking of fibers using barbed needles.

- Lamination and Reinforcement: For products like Laminated Air Filter Media With Mesh, multiple layers of nonwoven media, often with different fiber densities or properties, are combined. A reinforcing mesh (typically wire or expanded metal mesh) is then laminated onto the media using heat, adhesive, or ultrasonic bonding to provide structural support and prevent tearing or deformation.

- Specialized Treatments: Depending on the application, the media may undergo treatments for flame retardancy, antimicrobial properties, water repellency, or electrostatic charging (for enhanced particulate capture).

- Slitting and Packaging: The finished filter media rolls are slit to the required widths and packaged, often in protective wrapping to prevent contamination during transport and storage.

Throughout this process, stringent quality control measures are implemented. This includes continuous monitoring of media thickness, basis weight, air permeability, and initial filtration efficiency. Final products are tested against international standards like ISO 16890, ASHRAE 52.2, and EN 1822 to ensure compliance and consistent performance. Our internal QA/QC protocols adhere strictly to ISO 9001 guidelines.

Key Technical Parameters and Industry Standards

Selecting the appropriate filter media requires a deep understanding of its technical specifications and relevant industry standards. These parameters dictate the media’s effectiveness, longevity, and suitability for specific applications.

Critical Parameters for Filter Media:

- Efficiency: Measured by the percentage of particles captured at a given size. Standards like ASHRAE 52.2 (MERV ratings), EN 779 (G, M, F classes), and EN 1822 (E, H, U classes for HEPA filter media and ULPA) provide a standardized framework for classification.

- Pressure Drop (Initial Resistance): The resistance to airflow exerted by the media, measured in Pascals (Pa) or inches of water gauge (in. w.g.). A lower pressure drop typically indicates better energy efficiency of the system.

- Dust Holding Capacity (DHC): The total mass of dust that the media can hold before reaching a specified final pressure drop or efficiency degradation. A higher DHC translates to a longer service life for the filter.

- Air Permeability: The volume of air that can pass through a unit area of media at a specified pressure difference, indicating its openness and resistance to flow.

- Media Basis Weight: The weight of the media per unit area (e.g., g/m²), often correlating with media thickness and fiber density.

- Tensile Strength: The maximum stress the media can withstand before tearing, crucial for durability, especially for pleated configurations or media reinforced with a mesh.

- Thermal Stability & Chemical Resistance: Ability of the media to withstand high temperatures or exposure to specific chemicals without degradation.

Industry Standards Overview:

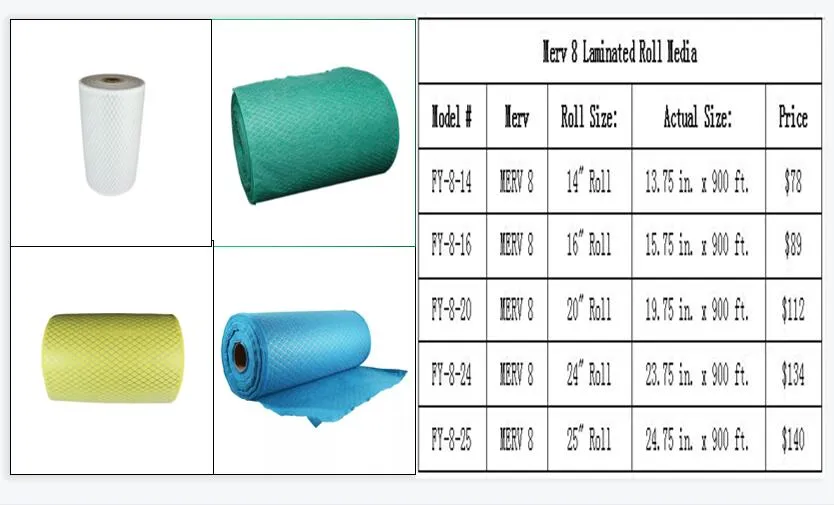

- ASHRAE 52.2 (MERV): Minimum Efficiency Reporting Value. Ranges from MERV 1 (lowest) to MERV 16+ (highest), classifying filters based on their ability to capture particles of specific sizes (0.3-10 µm). Widely used in North America.

- ISO 16890: A global standard replacing EN 779. It classifies air filters based on their ability to capture different size fractions of particulate matter (PM1, PM2.5, PM10) and coarse dust, providing a more real-world relevant efficiency assessment.

- EN 1822: Specifically for HEPA filter media and ULPA filters, classifying them by efficiency for the Most Penetrating Particle Size (MPPS), ranging from E10 to U17.

Our Laminated Air Filter Media With Mesh is rigorously tested to meet or exceed these standards, ensuring a product that delivers consistent, reliable performance. We provide detailed technical datasheets for all our products, offering full transparency on performance characteristics.

Applications Across Diverse Industries

The versatility of advanced filter media makes it indispensable across a multitude of industries, each with unique air quality requirements.

Key Application Sectors:

- HVAC Systems (Commercial & Residential): Essential for maintaining indoor air quality in offices, schools, hospitals, and homes. Our nonwoven synthetic filter media is widely used in pleated panel filters, bag filters, and rigid cell filters.

- Automotive Industry: Used in cabin air filters to protect vehicle occupants from pollen, dust, and pollutants, and in engine air intake filters to protect critical engine components from particulate contamination.

- Medical & Pharmaceutical: Critical for maintaining sterile environments in operating rooms, cleanrooms, and pharmaceutical manufacturing facilities. High-efficiency hepa filter media and ULPA media are paramount here.

- Food & Beverage: Ensuring hygiene and preventing contamination in food processing plants, especially where sensitive products are exposed to air.

- Electronics & Data Centers: Protecting sensitive electronic components from dust and airborne particles that can cause overheating and system failures.

- Industrial Filtration: From manufacturing plants (e.g., woodworking, welding fumes) to power generation facilities, industrial filter media is crucial for worker safety, equipment protection, and emission control. This includes specialized activated carbon air filter media for odor and VOC removal.

- Painting Booths: Capturing overspray and ensuring a clean painting environment, enhancing finish quality and protecting workers.

- Water Treatment & Petrochemical (Indirectly): While primarily for air, advanced filter media indirectly supports these industries by maintaining clean air in control rooms, laboratories, and sensitive equipment areas, which are vital for operational reliability and safety.

The specific advantages of our Laminated Air Filter Media With Mesh in these scenarios include enhanced structural stability, which allows for deeper pleating and higher dust holding capacity, translating to longer filter life and reduced maintenance cycles. Its low initial pressure drop also contributes to significant energy savings for the fan systems.

Advantages of Advanced Filter Media Solutions

Investing in high-quality filter media yields substantial benefits beyond mere particle capture. These advantages translate directly into operational efficiencies and cost savings for businesses.

Key Technical Advantages:

- Superior Filtration Efficiency: Modern filter media, especially those designed as hepa filter media or multi-layered synthetic media, can capture a broad spectrum of particulates, including fine dust (PM2.5, PM10), pollen, spores, and even certain aerosols.

- Extended Service Life: High dust holding capacity, often enhanced by advanced fiber configurations and structural support like mesh, means filters last longer, reducing replacement frequency and associated labor costs. Our Laminated Air Filter Media With Mesh consistently demonstrates superior DHC compared to single-layer alternatives.

- Energy Savings: A low initial and average pressure drop throughout the filter’s life directly reduces the energy consumption of HVAC fans and air handling units. This can lead to substantial operational cost savings over time. Industry studies show that a 10% reduction in static pressure can result in 15% energy savings.

- Enhanced Equipment Protection: Cleaner air entering machinery and sensitive components minimizes wear, prevents clogs, and reduces the risk of breakdowns, thereby extending equipment lifespan and decreasing maintenance expenditures.

- Improved Indoor Air Quality (IAQ): For occupied spaces, superior filtration contributes to a healthier environment, reducing respiratory issues and enhancing productivity. This is critical in commercial buildings, healthcare, and educational facilities.

- Moisture & Microbial Resistance: Nonwoven synthetic filter media inherently resist moisture absorption and microbial growth, preventing filter degradation and secondary contamination of the air stream.

- Corrosion Prevention (Indirect): By filtering corrosive particles and gases (when activated carbon is incorporated), the media protects downstream metal components from premature degradation, although direct anti-corrosion properties are related to the system’s overall design, not just the media itself.

Industry Trends and Future Outlook for Filter Media

The filter media landscape is continuously evolving, driven by global megatrends and technological advancements.

Key Trends Shaping the Filter Media Market:

- Sustainability & Eco-Friendly Materials: Growing demand for biodegradable, recyclable, or recycled filter media. Manufacturers are exploring plant-based fibers and more energy-efficient production processes.

- Miniaturization & Higher Efficiency: Development of ultra-fine fibers (e.g., nanofiber technology) for enhanced capture of sub-micron particles with minimal pressure drop, pushing the boundaries of hepa filter media and ULPA performance.

- Smart Filters & IoT Integration: Media with integrated sensors that monitor saturation levels, pressure drop, and even air quality, enabling predictive maintenance and optimized filter replacement cycles.

- Multi-functional Media: Combining particulate filtration with gas and odor adsorption (e.g., activated carbon air filter media), or antimicrobial properties, into a single media for comprehensive air purification.

- Increased Demand for Fine Particulate Filtration: Global health concerns over PM2.5 and PM1.0 are driving demand for higher efficiency media across all applications, from automotive cabin air to commercial HVAC.

- Customization & Niche Applications: A shift towards highly customized filter media solutions tailored to specific industry needs, challenging manufacturers to offer flexible production capabilities.

Our commitment to R&D ensures we stay at the forefront of these trends, continuously innovating our filter media products, including the Laminated Air Filter Media With Mesh, to meet future market demands.

Choosing the Right Filter Media: A Comparison Guide

The market offers a variety of filter media types, each with its own strengths. Understanding their differences is key to making an informed decision.

Common Filter Media Types and Their Characteristics:

| Media Type | Typical Material | Efficiency Range (ISO 16890 / ASHRAE MERV) | Key Advantages | Typical Applications |

|---|---|---|---|---|

| Fiberglass Media | Glass fibers | ePM10 (G4) to ePM1 (F9), MERV 6-16 | High efficiency, good dust loading for its type. | Industrial, commercial HVAC (older systems), HEPA filter media (with specific construction). |

| Nonwoven Synthetic Filter Media (Polypropylene/Polyester) | Polypropylene, Polyester | ePM10 (G3) to ePM1 (F9), MERV 5-16 | Moisture resistant, robust, lower pressure drop, versatile. | Modern HVAC, automotive, general industrial, pre-filtration. |

| Laminated Air Filter Media With Mesh (Our Product) | Synthetic fibers, often polyester, with integrated metal or synthetic mesh. | ePM10 (G3) to ePM1 (F9), MERV 5-16+ (depending on specific layers) | Exceptional structural integrity, high DHC, low pressure drop, durability, enhanced pleating. | High-airflow HVAC, critical industrial applications, pre-filtration for fine filters. |

| HEPA Filter Media | Borosilicate glass microfibers, synthetic blends | E10-U17 (EN 1822), MERV 17-20 | Highest efficiency for sub-micron particles, critical for sterile environments. | Cleanrooms, hospitals, pharmaceutical, electronics manufacturing. |

| Activated Carbon Air Filter Media | Nonwoven substrate impregnated with activated carbon | Primarily for molecular filtration, some particulate. | Removes odors, VOCs, harmful gases. | Laboratories, commercial kitchens, chemical plants, automotive. |

When considering filter media for sale, it’s crucial to assess not just the initial cost, but also the total cost of ownership, including energy consumption, replacement frequency, and labor. Our technical team is available to help you select the optimal media for your specific requirements.

Custom Solutions and Partnership Approach

Recognizing that every industrial application is unique, we excel in providing customized filter media solutions. Our expertise lies in collaborating closely with clients to develop media that perfectly fits their specific performance, size, and material requirements.

Our Customization Capabilities Include:

- Tailored Efficiency Levels: Adjusting fiber density and layering for precise MERV/ISO/EN classification, including options for specialized hepa filter media or higher ePM ratings.

- Varying Thickness & Basis Weight: Producing media rolls in specific thicknesses and weights to optimize pressure drop and dust holding capacity for given airflow rates.

- Specific Material Blends: Incorporating unique fiber types, activated carbon, or other additives for enhanced chemical resistance, odor adsorption, or flame retardancy.

- Integrated Mesh Options: Offering different mesh materials (e.g., galvanized steel, aluminum, plastic) and patterns for varying degrees of reinforcement in our Laminated Air Filter Media With Mesh.

- Roll Width & Length Customization: Supplying filter media for sale in precise roll dimensions to minimize waste in filter manufacturing processes.

- Special Treatments: Applying hydrophobic, oleophobic, or antimicrobial finishes as required by application.

Our engineering team works hand-in-hand with your R&D department to ensure the customized filter media not only meets but exceeds performance expectations, providing a competitive edge in your final products. We have over 15 years of experience in the filtration industry, partnering with leading filter manufacturers globally.

Real-World Applications and Case Studies

The practical impact of superior filter media is best illustrated through real-world applications.

Case Study 1: Large Commercial HVAC System Upgrade

- Challenge: A major office complex in a highly polluted urban area faced issues with high energy consumption from their HVAC system due to excessive pressure drop and frequent filter replacements (every 3 months) caused by rapid clogging of conventional G4 media.

- Solution: We supplied a customized Laminated Air Filter Media With Mesh designed for a higher dust holding capacity and optimized for lower initial pressure drop while maintaining an ePM10 (G4) efficiency. The integrated mesh provided superior support, allowing for deeper pleats.

- Result: Filter service life extended to 6-8 months, reducing filter replacement frequency by over 50%. The average pressure drop decreased by 15%, leading to an estimated 10-12% reduction in HVAC energy consumption. Client feedback highlighted significant savings in maintenance costs and improved indoor air quality.

Case Study 2: Automotive Paint Booth Filtration

- Challenge: An automotive manufacturing plant needed a robust pre-filter media for their paint booth air intake that could withstand high airflow, capture paint overspray, and resist degradation from volatile organic compounds (VOCs), while ensuring consistent air quality for a flawless finish.

- Solution: We provided a heavy-duty nonwoven synthetic filter media with a durable mesh backing, designed for high tensile strength and a specific coating to enhance paint particle capture and prevent clogging. It also featured a hydrophobic treatment.

- Result: The new media significantly improved capture efficiency, reducing contamination and rework in the paint booth. The filters maintained structural integrity even under continuous high airflow, leading to extended service intervals and higher quality finished products.

Ensuring Trust: Quality, Warranty, and Support

Our commitment to quality and customer satisfaction is paramount. We understand that for B2B decision-makers, reliability and support are as critical as product performance when sourcing filter media for sale.

Our Assurance to You:

- Certified Quality: All our filter media products, including Laminated Air Filter Media With Mesh, are manufactured under ISO 9001 certified quality management systems. We conduct rigorous in-house testing following international standards (ISO 16890, ASHRAE 52.2, EN 1822 where applicable) to ensure every roll meets our high performance benchmarks.

- Transparent Data: We provide comprehensive technical specifications and performance data for all our filter media, ensuring you have all the necessary information for informed procurement and filter design.

- Reliable Delivery: With a robust supply chain and efficient logistics, we are committed to meeting agreed-upon delivery schedules. Our typical lead time for standard filter media orders is 2-4 weeks, with expedited options available for urgent requirements.

- Performance Warranty: We stand behind the quality and performance of our filter media. Our products come with a standard warranty against manufacturing defects and for consistent performance within specified parameters under normal operating conditions. Specific warranty details are provided with each order.

- Dedicated Customer Support: Our team of technical experts and sales professionals is available to provide pre-sales consultation, assist with product selection, offer technical support during integration, and address any post-sales inquiries. We prioritize clear communication and swift resolution.

Frequently Asked Questions (FAQ) about Filter Media

Here are answers to common questions about filter media and our products:

Q: What is the primary advantage of Laminated Air Filter Media With Mesh over standard nonwoven media?

A: The integrated mesh provides significantly enhanced structural integrity, preventing media sag, tearing, and deformation, especially in high-airflow applications or when the media is deeply pleated. This leads to higher dust holding capacity, longer filter life, and more consistent performance over time compared to media without reinforcement.

Q: How does MERV rating relate to ISO 16890 and EN 1822 for filter media?

A: MERV (ASHRAE 52.2) classifies filters based on their ability to remove particles from 0.3 to 10 micrometers. ISO 16890, a newer global standard, classifies filters based on their efficiency against PM1, PM2.5, and PM10 fractions, which provides a more real-world relevant assessment. EN 1822 is specifically for HEPA filter media and ULPA filters, measuring efficiency at the Most Penetrating Particle Size (MPPS) for extremely fine particle capture. While there are conversion charts, direct comparison can be complex due to different testing methodologies.

Q: Can your filter media be used in environments with high humidity?

A: Yes, our nonwoven synthetic filter media, including the Laminated Air Filter Media With Mesh, is inherently resistant to moisture and does not degrade in humid conditions, unlike some traditional fiberglass media. This also helps prevent microbial growth on the media surface.

Q: Do you offer activated carbon air filter media?

A: Yes, we supply activated carbon air filter media designed for the adsorption of gaseous contaminants, odors, and VOCs. These are available in various forms, often integrated into a particulate filtration layer for comprehensive air purification.

Q: What is the typical lead time for custom filter media for sale orders?

A: Lead times for custom orders can vary depending on material availability, complexity, and order volume. We typically quote 4-8 weeks for new custom developments, including testing and sample approval. For repeat custom orders, lead times are significantly reduced, similar to standard products.

Conclusion: Partnering for Filtration Excellence

The selection of superior filter media is a strategic decision that directly impacts operational costs, equipment longevity, and the health and safety of personnel. Our Laminated Air Filter Media With Mesh, along with our comprehensive range of nonwoven synthetic filter media and specialized solutions like hepa filter media and activated carbon air filter media, is engineered to meet the most demanding industrial and commercial requirements. By choosing our high-performance filter media for sale, you are investing in a future of cleaner air, reduced energy consumption, and reliable system performance. We invite you to partner with us to unlock the full potential of advanced air filtration for your business.

References

- ASHRAE Standard 52.2-2017: Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size.

- ISO 16890-1:2016: Air filters for general ventilation — Part 1: Technical specifications, requirements and classification system based upon particulate matter efficiency (ePM).

- EN 1822-1:2019: High efficiency air filters (EPA, HEPA and ULPA) — Part 1: Classification, performance testing, marking.

- International Energy Agency (IEA) reports on industrial energy efficiency.

- Frost & Sullivan Market Insights: Global Air Filtration Market Forecasts.

- Air & Waste Management Association (AWMA) journals on air pollution control technologies.

- National Air Filtration Association (NAFA) Guide to Air Filtration.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog