Field Notes on Fiberglass Pocket Filter Media: what actually matters in 2025

If you’re speccing HVAC upgrades, Fiberglass Filter Media keeps popping up—partly because it balances low resistance with steady capture efficiency, and partly because supply chains for synthetics have been bumpy. From my latest visits to Handan and a couple of paint plants, it’s clear the sweet spot right now is laminated composites with stitched seams and stable F7–F9 performance.

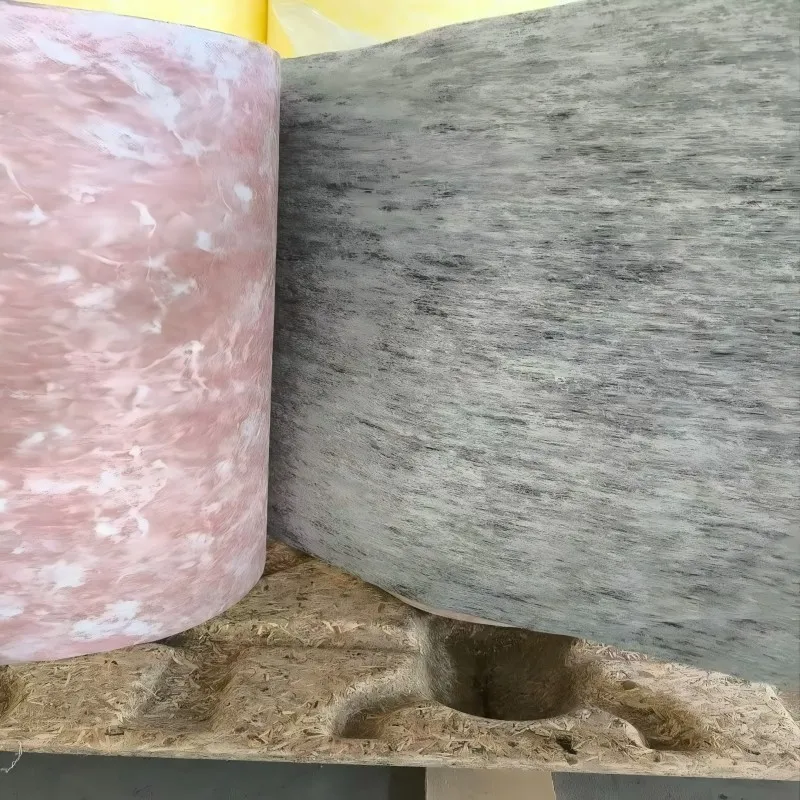

This particular media—“Fiberglass Pocket Filter Media,” made in Second Buliding and Studying No21 shiji street, Handan, Hebei China—uses ultra fiberglass fibers in a laminated stack, then a stitched sewing process to keep pleat geometry honest under load. Features are simple: low resistance, high efficiency, sane pricing. Many customers say it “just works,” which, to be honest, is what you need in bag and panel filters.

Industry pulse and where it’s used

Trends: tighter IAQ targets (ISO 16890), more data logging, and a nudge toward MERV 13+ in commercial buildings. You’ll see Fiberglass Filter Media in hospitals, pharma auxiliaries, food packaging, battery plants, and especially automotive paint booths where temperature and overspray demand stable media.

How it’s made (short version)

- Materials: ultra fiberglass fiber web, support scrim, optional activated carbon interlayer.

- Methods: carding/airlay → lamination → precision stitching for pocket integrity → heat setting.

- Testing: ISO 16890 (ePM1/ePM2.5), ASHRAE 52.2 (MERV), pressure drop @ 2.5 m/s, dust holding.

- Service life: around 3–12 months; paint booths and dusty sites trend shorter. Real-world use may vary.

- Industries: HVAC in commercial buildings, clean auxiliaries, paint lines, electronics prefilters.

Product specifications

| Parameter | Typical value (≈) |

|---|---|

| Efficiency class | F5–F9 (ISO 16890 ≈ ePM2.5 50–85%); custom up to MERV 15 available |

| Initial ΔP @ 2.5 m/s | 70–140 Pa |

| Final ΔP (recommended) | 300–450 Pa |

| Dust holding capacity | 250–450 g/m² |

| Basis weight / thickness | 120–260 g/m²; 6–18 mm |

| Temperature limit | ≤ 120°C continuous |

| Fire performance | UL 900 Class 2 / DIN 53438-F1 options |

| Formats | Rolls (0.6–2.0 m width), custom cut for pockets/panels |

Where it shines

- Bag filters in AHUs where low energy is a priority.

- Panel prefilters upstream of HEPA in labs (keeps HEPA cleaner, longer).

- Paint booths: stable geometry, consistent overspray capture.

Vendor snapshot (what buyers compare)

| Vendor | Lead time | Customization | Certs |

|---|---|---|---|

| Specialist manufacturer (Hebei) | 10–18 days | Widths, basis weight, carbon layer | ISO 9001, UL 900 (option) |

| General HVAC supplier | 2–4 weeks | Limited SKUs | Basic COA |

| Low-cost importer | Variable | Minimal | Mixed documentation |

Customization, QA, and real test data

Typical F7 build I observed tested at ePM2.5 ≈ 75% ±5%, initial ΔP 95 Pa @ 2.5 m/s, dust holding ≈ 350 g/m² under ISO A2 dust. Certificates include ISO 9001 factory QA and, on request, UL 900 Class 2. Ask for an ISO 16890 report plus ASHRAE 52.2 MERV mapping; it saves back-and-forth later.

Mini case notes

- Hospital upgrade, MERV 13 target: swapped to Fiberglass Filter Media F7 pockets; coil ΔP dropped ≈ 12% and HEPA changeouts stretched by a quarter.

- Auto paint line: F8 with carbon layer; odor peaks reduced, and booth downtime shrank—operators said “less sagging” under heat.

Customer feedback is consistent: low resistance out of the box, predictable loading curve, and less variability batch-to-batch than some synthetics. Surprisingly, installers love the stitched seams more than they’ll admit—it keeps pocket shape during rush installs.

Origin: Second Buliding and Studying No21 shiji street, Handan, Hebei China. For specs, quotes, or COAs, reference Fiberglass Filter Media “Pocket” series and note your target class (F5–F9) and face velocity.

Authoritative citations

- ISO 16890-1/2/3/4: Air filters for general ventilation (particulate matter measurement and classification).

- ASHRAE Standard 52.2-2017 (or latest): Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size.

- EN 779:2012 (historical reference; superseded by ISO 16890) — classification of air filters.

- UL 900: Standard for Air Filter Units; DIN 53438 (F1) for fire behavior of filter media.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog