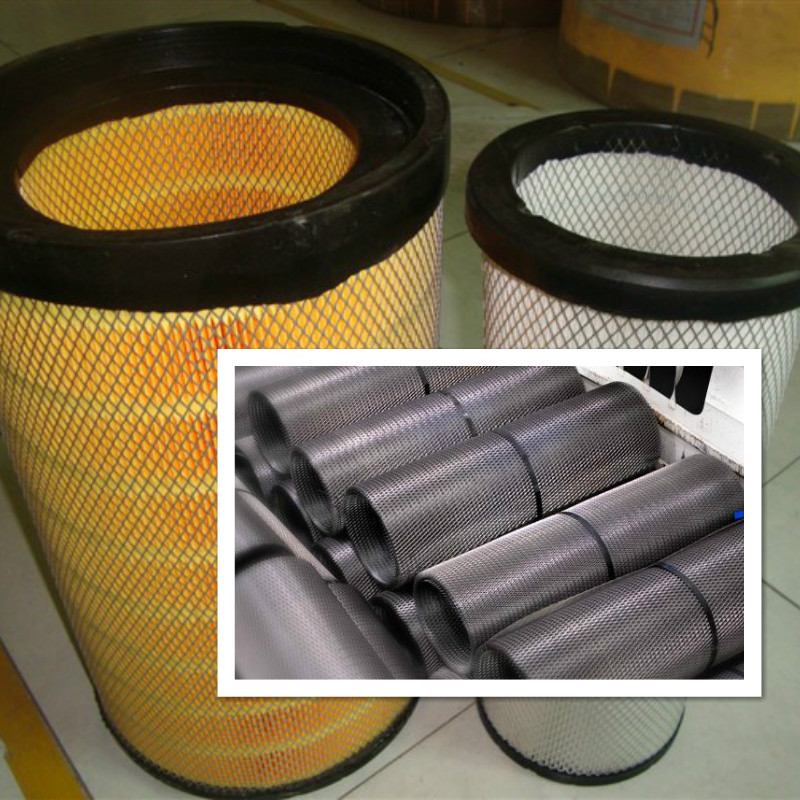

Expanded Metal Mesh for Air Filters: What Pros Are Actually Using in 2025

If you’ve been around filter frames and media guards long enough, you know the backbone isn’t glamorous—it’s the reinforcement. The first time I ran my hand across

Expanded Metal Mesh For Air Filters, I was surprised by how much rigidity you can get from a thin, cleverly slit-and-stretched sheet. It’s simple, tough, and—when specified right—quietly improves airflow and service life. Lately, demand is up in HVAC OEM, paint booths, and even battery gigafactories (yes, really).

Quick Specs (real-world use may vary)

| Thickness | ≈0.2–6 mm (custom) |

| Strand thickness | ≈0.5–8 mm |

| SWD (short way diamond) | ≈2.5–100 mm |

| LWD (long way diamond) | ≈4.5–200 mm |

| Surface treatment | Powder coated, galvanized |

| Common materials | Low-carbon steel, 304/316 SS, 3003/5052 Al |

Many customers say the sweet spot for pressure drop sits with medium diamonds (say, 10–20 mm LWD) and a light gauge—stiff enough to support pleats, open enough to breathe.

Process flow and testing (the unsexy bits that matter)

- Materials: coil-fed low-carbon steel, aluminum, or stainless.

- Method: slitting + expanding in one pass; optional flattening; then shearing to size.

- Finishing: hot-dip galvanizing (ASTM A123) or powder coat (adhesion per ASTM D3359; thickness per ASTM D7091).

- Corrosion check: salt spray ≈ 240–500 h (ASTM B117/ISO 9227), depending on finish.

- Air performance: open area typically 60–80%; added pressure drop ≈ 5–25 Pa at 2.0 m/s, mesh-dependent.

- Service life: commonly 3–7 years in HVAC; faster in coastal or acid mist environments—choose SS or heavier zinc there.

- Standards context: Used in filter assemblies tested to ISO 16890 and ASHRAE 52.2.

Where it’s used

Commercial HVAC prefilters and pleats, cleanroom pre-screens, auto paint booths, turbine inlets, compressor rooms, food & beverage makeup air, battery/EV dry rooms, and dust collector panel supports. Surprisingly versatile.

Why spec Expanded Metal Mesh For Air Filters?

– Consistent rigidity-to-weight ratio; doesn’t unravel like woven wire if cut oddly.

– High open area for airflow; edges are burr-reduced when flattened—less media damage.

– Customizable diamond geometry to tune stiffness and pressure drop.

– Coatings that actually survive damp return-air sections.

Vendor snapshot (what to look for)

| Criteria | FiltersMaterial (Manufacturer) | Typical Trader | Local Fabricator |

|---|---|---|---|

| Origin | Second Buliding and Studying No21 shiji street, Handan, Hebei China | Mixed | Local shop |

| Mesh control | In-house expansion + flattening | Depends on supplier | Good for short runs |

| Certs | ISO 9001; RoHS/REACH-compliant coatings | Varies | Varies |

| Lead time | Stable for repeats | Subject to import cycles | Fast prototypes |

Customization tips

- Match LWD/SWD to pleat pitch to avoid print-through.

- Go aluminum for weight-sensitive rooftop units; stainless for wash-down or coastal.

- Powder coat in RAL neutrals if media abrasion shows up in QA (I’ve seen it fix those nagging fiber-shed complaints).

Mini case files

– Automotive paint line: galvanized Expanded Metal Mesh For Air Filters upgraded from woven guard reduced changeouts from 3 to 6 months; ΔP at 2.5 m/s dropped ≈ 9 Pa due to higher open area.

– HVAC OEM: switched to 5052 aluminum flattened Expanded Metal Mesh For Air Filters, saving ~18% weight per panel; shipping damage claims fell noticeably (anecdotal, but echoed by two distributors).

Standards and references

- ISO 16890: Air filters for general ventilation.

- ASHRAE 52.2: Method of testing general ventilation air-cleaning devices.

- ASTM F1267: Standard Specification for Expanded Metal.

- ASTM A123/A123M: Standard for zinc (hot-dip) coatings on iron and steel.

- ASTM B117 / ISO 9227: Salt spray corrosion tests for coatings.

- ASTM D3359 & D7091: Coating adhesion and thickness measurement.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog