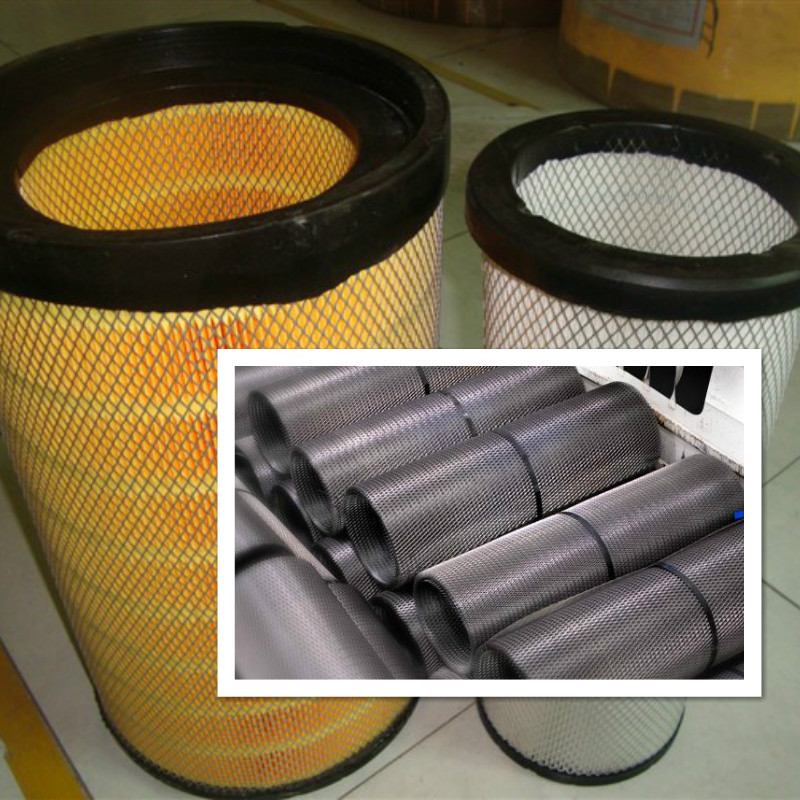

Expanded Metal Mesh That Actually Helps Filters Breathe

If you’ve ever wondered why some filter packs seem to hold their shape under real airflow (and some collapse at the first sneeze), a lot of it comes down to the support layer. That’s where Expanded Metal Mesh For Air Filters earns its keep—quietly, reliably, and frankly, indispensably.

What’s trending (and why it matters)

Three big shifts are reshaping filter backers: higher efficiency media (ISO 16890), tighter energy targets, and rougher duty cycles in industrial plants. In practice, many customers say they need stiffer mesh with lower pressure drop. It seems simple, but balancing stiffness, open area, and corrosion resistance is the whole game.

Core specs at a glance

| Parameter | Typical Range | Notes (real-world use may vary) |

| Thickness | 0.2–6 mm | Custom to support pleat depth and frame. |

| Strand thickness | 0.5–8 mm | Heavier strands = higher rigidity. |

| SWD / LWD | SWD ≈ 2.5–100 mm; LWD ≈ 4.5–200 mm | Cell size drives airflow and support. |

| Surface | Galvanized / Powder coated | Coating picked by corrosion class. |

| Open area | ≈ 60–80% | Lower ΔP, better dust loading. |

Origin: Second Buliding and Studying No21 shiji street, Handan, Hebei, China. To be honest, the supply chain here is deeply specialized in metal working, and it shows in consistency lot-to-lot.

Process flow (how it’s built)

- Material: low-carbon steel, aluminum, or stainless (304/316 for harsh duty).

- Slitting and expanding: per ASTM E2016; tuned SWD/LWD for target open area.

- Flattening or raised finish: depends on pleat spacing and contact with media.

- Cut-to-size and edging: burr control to protect media fibers.

- Coating: galvanizing or powder coat; corrosion testing per ISO 9227 (NSS).

- QC: dimensional checks, tensile test, airflow/ΔP check on fixture, edge sharpness.

Applications

HVAC pleated panels, HEPA prefilter cages, turbine intakes, spray booth exhaust, compressor rooms, and food/beverage prefilters. In fact, Expanded Metal Mesh For Air Filters is often used as the upstream guard and downstream pleat support simultaneously.

Why this mesh works

- Rigid support under high face velocity—less pleat sag, longer media life.

- High open area keeps pressure drop in check.

- Reliable coatings for wet, coastal, or slightly acidic environments.

- Easy to form and spot-weld into frames without distortion.

Vendor comparison (quick reality check)

| Criteria | Handan Manufacturer | Generic Broker | Notes |

| SWD/LWD tolerance | ±0.5 mm typical | ±1–2 mm | Tighter fit reduces media snag. |

| Coating durability | 240–480 h NSS | 120–240 h | Project dependent. |

| Lead time | 10–18 days | 20–35 days | Rush available. |

Case study: paint booth upgrade

A mid-size auto refinisher swapped in Expanded Metal Mesh For Air Filters with 70% open area, flattened pattern, powder coat. Result: initial pressure drop dropped by ≈18 Pa at 2.5 m/s and pleat deformation complaints went to zero. Service life extended ~22% before replacement—confirmed by their maintenance logs. Not flashy, but profitable.

Testing, certifications, and data points

- Mechanical and dimensional: ASTM E2016 compliance.

- Filter performance context: ISO 16890 and ASHRAE 52.2 frameworks for ΔP check.

- Corrosion: ISO 9227 (NSS) 240–480 h typical, coating-dependent.

- Environmental: RoHS and REACH statements available; ISO 9001 factory QA.

- Typical numbers: tensile strength ≈ 240–380 MPa (low-carbon steel); bend cycles >100 without strand fracture; edge burr

Customization tips

For high-velocity HVAC, pick 65–75% open area and galvanized finish. For coastal or washdown, powder coat or stainless. For deep pleats, consider raised mesh downstream and flattened upstream. And, I guess this is obvious, but always validate ΔP at operating face velocity—bench numbers can mislead.

Service life and maintenance

Mesh typically outlasts the media by years; expect 3–10 years depending on corrosion class and handling. Inspect edges during change-outs—most damage happens then.

Ready to spec? Share target SWD/LWD, open area, finish, sheet size, and packaging. It saves a dozen emails.

References

- ISO 16890: Air filters for general ventilation. https://www.iso.org/standard/71938.html

- ASHRAE 52.2-2017: Method of Testing General Ventilation Air-Cleaning Devices. https://www.ashrae.org

- ASTM E2016: Standard Specification for Industrial Expanded Metal. https://www.astm.org/e2016

- ISO 9227: Corrosion tests in artificial atmospheres — Salt spray tests. https://www.iso.org/standard/63543.html

- RoHS Directive 2011/65/EU and REACH Regulation EC 1907/2006. https://ec.europa.eu/environment

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog