Navigating the Market for High-Performance Activated Carbon Filters

In today’s industrial landscape, stringent environmental regulations, growing public health concerns, and the relentless pursuit of operational efficiency are driving an unprecedented demand for advanced purification solutions. Among these, activated carbon filters stand out as a cornerstone technology for effectively removing a vast array of contaminants from water, air, and process streams. This comprehensive guide delves into the specifics of finding a premium activated carbon filter for sale, exploring the technical intricacies, application versatility, and crucial vendor considerations that B2B decision-makers and engineers require. The market for activated carbon filter media is expanding rapidly, fueled by innovations in material science and a global push for cleaner industrial practices. Understanding the nuances of these critical components, especially sophisticated products like our Activated Carbon Composite Filter Media, is essential for optimizing purification processes across diverse sectors.

Industry trends indicate a shift towards highly specialized and composite filter media, offering enhanced adsorption capabilities, extended service life, and reduced operational footprints. With increasing awareness about micropollutants, volatile organic compounds (VOCs), and emerging contaminants, the reliance on robust activated carbon water filter media and air purification solutions has never been more critical. Procurement professionals are seeking not just products, but holistic solutions from reputable activated carbon filter suppliers who can provide tailored advice and guaranteed performance.

The Advanced Science Behind Activated Carbon Filters

Activated carbon’s unparalleled purification capability stems from its highly porous structure, which provides an immense surface area for adsorption. This intricate network of micropores, mesopores, and macropores allows it to physically trap molecules (physical adsorption) and, in some cases, chemically react with them (chemical adsorption or chemisorption). The primary mechanism is van der Waals forces, drawing organic molecules into the carbon’s pores.

Key parameters defining activated carbon performance include its Iodine Number (indicating micropore content and activity), BET Surface Area (total surface area, typically 500-1500 m²/g), and pore size distribution. Specialized carbon filter media can be impregnated with chemicals to enhance removal of specific contaminants, such as hydrogen sulfide or ammonia, through catalytic oxidation. This level of technical understanding is vital when evaluating an activated carbon filter for sale, ensuring it aligns with the specific contaminant profile and operational demands.

Manufacturing Process: From Raw Material to Advanced Composite Media

The production of high-performance Activated Carbon Composite Filter Media is a meticulous multi-stage process, ensuring optimal pore structure, mechanical strength, and contaminant removal efficiency.

- Raw Material Selection: The foundation of any quality activated carbon is its precursor material. Common sources include coconut shell, bituminous coal, lignite, wood, and peat. Coconut shell activated carbon is favored for water treatment due to its high microporosity, while coal-based carbon offers good macroporosity, suitable for larger organic molecules. Our composite media carefully selects materials based on targeted application performance.

- Carbonization (Pyrolysis): The chosen raw material undergoes pyrolysis in an inert atmosphere at temperatures between 600-900°C. This process removes non-carbon elements (volatiles) and creates the initial porous carbon structure. The material becomes char, rich in fixed carbon.

-

Activation: This is the most critical step, expanding the pore structure and increasing surface area.

- Steam Activation (Physical Activation): The carbonized material is exposed to steam at high temperatures (700-1100°C). The steam acts as an oxidizing agent, selectively gasifying carbon atoms, enlarging pores, and creating new ones. This method is common for high-quality granular activated carbon.

- Chemical Activation: The raw material is impregnated with a chemical agent (e.g., phosphoric acid, zinc chloride) before carbonization. This agent promotes dehydration and prevents the formation of tar, leading to a highly porous carbon upon heating. This process often yields powdered activated carbon (PAC) with specific pore characteristics.

- Impregnation (Optional): For specialized applications requiring enhanced removal of specific contaminants (e.g., ammonia, hydrogen sulfide, mercury), the activated carbon is impregnated with catalytic agents like potassium iodide, metal oxides, or acids.

- Granulation/Shaping: The activated carbon is processed into various forms – granular (GAC), powdered (PAC), extruded (pellets), or cloth – to suit different filter designs and application requirements. Our composite media involves precise shaping and sizing for optimal flow and filtration efficiency.

- Composite Formation & Binding: For “Activated Carbon Composite Filter Media,” the activated carbon particles are carefully combined with a high-performance polymer matrix and other filter layers. This process involves advanced binding techniques, often including casting or molding, to create a durable, integrated filter structure that maximizes contact time and minimizes bypass.

- Quality Control & Testing: Throughout the entire manufacturing chain, rigorous testing is conducted. This includes evaluating parameters like iodine number, BET surface area, bulk density, ash content, pH, and adsorption kinetics. Products are tested against international standards such as ISO 9001, ASTM (e.g., ASTM D2866 for total ash content), and ANSI standards to ensure consistent quality and performance. Our filter elements are also subjected to pressure drop tests, structural integrity assessments, and service life simulations.

The typical service life of an activated carbon filter varies significantly based on contaminant loading, flow rates, and the specific application, ranging from a few months to several years. In target industries like petrochemicals, metallurgy, and water supply & drainage, these filters are engineered for high-volume, continuous operation, demonstrating advantages in energy saving through optimized flow dynamics and superior corrosion resistance due to robust composite construction.

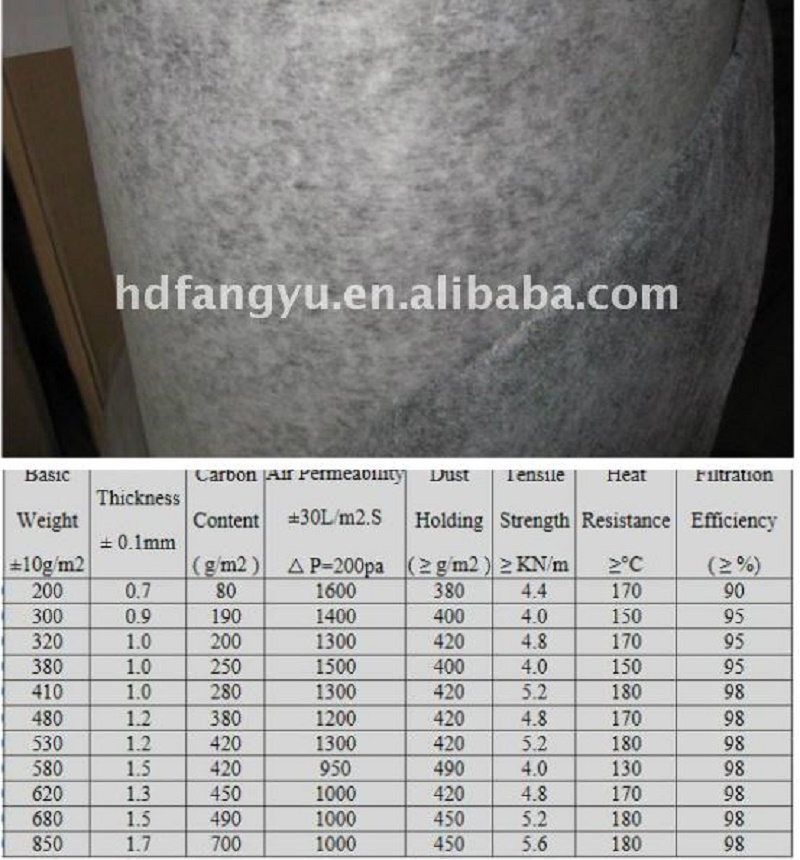

Technical Specifications & Performance Data: Activated Carbon Composite Filter Media

Selecting the right activated carbon filter for sale requires a detailed understanding of its technical specifications. Our Activated Carbon Composite Filter Media is engineered to provide superior performance across a range of critical parameters, ensuring efficient and reliable purification.

| Parameter | Unit | Value/Range | Test Method/Standard |

|---|---|---|---|

| Iodine Number | mg/g | ≥ 1000 | ASTM D4607 / ISO 13197 |

| BET Surface Area | m²/g | ≥ 1100 | ASTM D6556 |

| CTC Adsorption | % (w/w) | ≥ 55 | ASTM D3467 |

| Bulk Density | g/cm³ | 0.45 – 0.55 | ASTM D2854 |

| Ash Content | % (w/w) | ≤ 5.0 | ASTM D2866 |

| Hardness/Abrasion No. | % | ≥ 95 | ASTM D3802 |

| pH (aqueous extract) | – | 6.0 – 8.0 | ASTM D3838 |

| Particle Size Distribution | Mesh (Avg.) | Available in various grades (e.g., 8×30, 12×40) | ASTM D2862 |

| Moisture Content | % (w/w) | ≤ 5.0 | ASTM D2867 |

These specifications are crucial for engineers to predict the performance and longevity of the filter in specific applications. Our Activated Carbon Composite Filter Media is designed to meet or exceed these benchmarks, ensuring consistent and reliable purification outcomes.

Diverse Application Scenarios Across Key Industries

The versatility of activated carbon filters makes them indispensable across a multitude of industrial sectors. Our Activated Carbon Composite Filter Media is designed to excel in challenging environments, offering significant advantages such as energy saving, corrosion resistance, and high efficiency.

-

Water Treatment & Purification:

- Municipal Water Treatment: Removal of chlorine, chloramines, taste, odor, and organic contaminants from drinking water.

- Industrial Wastewater Treatment: Adsorption of dyes, phenols, heavy metals, and persistent organic pollutants from effluent streams.

- Ultrapure Water Production: Polishing step to remove trace organics that could foul membranes or interfere with semiconductor manufacturing.

-

Air Purification & Gas Phase Applications:

- HVAC Systems: Removal of odors, VOCs, and other airborne contaminants in commercial and industrial buildings.

- Industrial Emission Control: Adsorption of sulfur compounds, nitrogen oxides, mercaptans, and other harmful gases from industrial stacks.

- Solvent Recovery: Capturing valuable organic solvents from air streams in printing, painting, and chemical manufacturing.

-

Food & Beverage Industry:

- Decolorization: Removal of undesirable colors from sugar syrups, edible oils, and fruit juices.

- Taste & Odor Improvement: Enhancing the sensory quality of various liquid food products.

-

Chemical & Pharmaceutical Manufacturing:

- Catalyst Support: Activated carbon can act as a substrate for various catalysts in chemical reactions.

- Product Purification: Removal of impurities, by-products, and decolorization in fine chemical and pharmaceutical synthesis.

-

Oil & Gas Industry:

- Glycol Purification: Removing hydrocarbons and degradation products from glycol used in natural gas dehydration.

- Amine Sweetening: Filtration of contaminants from amine solutions used to remove H2S and CO2 from gas streams.

These scenarios highlight why businesses consistently seek a reliable activated carbon filter for sale, recognizing its essential role in maintaining product quality, environmental compliance, and worker safety.

Unrivaled Technical Advantages of Our Activated Carbon Composite Filter Media

Our Activated Carbon Composite Filter Media is not merely a filter; it’s a meticulously engineered solution designed to deliver superior performance and long-term value.

- Superior Adsorption Capacity: Leveraging premium raw materials and optimized activation processes, our media exhibits exceptionally high Iodine and BET surface areas. This translates to a significantly greater capacity for adsorbing organic contaminants, enabling longer operational cycles and fewer change-outs compared to conventional carbon filter media.

- Broad Spectrum Contaminant Removal: The carefully controlled pore size distribution within our composite media ensures effective removal of a wide range of molecular sizes, from small chlorinated byproducts to larger complex organic molecules and even certain dissolved metals. This versatility reduces the need for multiple filtration stages.

- Enhanced Longevity & Cost-Effectiveness: The composite structure provides robust mechanical integrity, minimizing attrition and channeling. This contributes to a prolonged service life, reducing maintenance frequency and overall operational expenditure. The high adsorption capacity also delays breakthrough, further extending filter life.

- Optimized Flow Dynamics: Our composite media is designed for minimal pressure drop, even at high flow rates. This “energy saving” aspect reduces the power consumption of pumps and fans, leading to significant operational cost savings over the filter’s lifetime, without compromising filtration efficiency.

- Corrosion Resistance & Chemical Stability: The binder materials and overall construction of our composite filters are chosen for their excellent resistance to a broad range of industrial chemicals, pH fluctuations, and high temperatures, ensuring reliable performance in harsh industrial environments and contributing to the filter’s “corrosion resistance.”

- Consistency and Reliability: Manufactured under strict quality controls and certified to ISO standards, each batch of our Activated Carbon Composite Filter Media delivers consistent performance, crucial for sensitive applications and regulatory compliance.

Vendor Selection & Comparison Criteria for Activated Carbon Filter Suppliers

Choosing the right activated carbon filter suppliers is as crucial as selecting the right product. A reliable vendor offers more than just filters; they provide expertise, support, and a commitment to long-term performance. When searching for an activated carbon filter for sale, consider the following:

- Technical Expertise & R&D: Does the supplier demonstrate deep knowledge of activated carbon science, adsorption kinetics, and application engineering? Look for evidence of ongoing research and development in new media formulations and filter technologies.

- Quality Certifications & Compliance: Verify certifications like ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and specific product-related certifications (e.g., NSF/ANSI standards for drinking water components if applicable).

- Customization Capabilities: Can they offer tailored solutions to meet unique process requirements, including different media types, sizes, or impregnated carbons?

- Reliability & Lead Times: A strong supply chain and efficient logistics are critical for timely delivery and avoiding operational disruptions. Inquire about typical lead times and inventory management.

- After-Sales Support & Technical Services: This includes technical assistance, troubleshooting, performance monitoring, and guidance on filter change-out schedules.

- Sustainability Practices: A commitment to environmentally responsible sourcing and manufacturing.

To further illustrate the options available, consider a comparison of common activated carbon forms:

| Feature | Granular Activated Carbon (GAC) | Powdered Activated Carbon (PAC) | Extruded Activated Carbon (EAC) | Composite Media (e.g., FiltersMaterial’s) |

|---|---|---|---|---|

| Form | Irregularly shaped particles (0.2-5 mm) | Fine powder (<0.18 mm) | Cylindrical pellets (0.8-5 mm) | Integrated structure, often pleated or block |

| Application | Fixed beds, continuous flow (water treatment) | Batch processes, dosing (emergency spill, taste/odor) | Gas phase adsorption, solvent recovery | Liquid & gas filtration, high flow, robust use |

| Pressure Drop | Moderate | High (if not handled properly) | Low | Very Low (optimized design) |

| Mechanical Strength | Good | Poor (dusting) | Excellent | Excellent (due to binding/matrix) |

| Adsorption Kinetics | Good (diffusion limited) | Very Fast | Good | Optimized for efficiency |

| Cost Effectiveness | High | Low (per batch) | High (specialized) | Excellent (long life, high performance) |

Tailored Excellence: Customized Activated Carbon Filter Solutions

Off-the-shelf solutions rarely meet the precise demands of complex industrial processes. As a leading provider, we specialize in delivering customized activated carbon filter for sale solutions, meticulously engineered to address specific contaminant profiles, flow rates, pressure tolerances, and regeneration requirements. Our collaborative approach involves:

- Detailed Needs Assessment: Understanding the precise nature of the contaminant, concentration levels, desired effluent quality, operating temperature, pressure, and flow dynamics.

- Media Selection & Blending: Advising on the optimal activated carbon base (e.g., coconut, coal, wood), its form (granular, extruded), and, if necessary, impregnating it with specific chemicals to target particular pollutants (e.g., impregnated carbon for H2S removal).

- Filter Design & Configuration: Developing bespoke filter geometries, housing materials, and internal structures to optimize contact time, minimize pressure drop, and ensure mechanical durability. This can include specialized composite designs for unique applications.

- Prototyping & Testing: Creating and rigorously testing prototypes under simulated operating conditions to validate performance before full-scale deployment.

- System Integration Support: Providing guidance and technical assistance for seamless integration of customized filters into existing or new purification systems.

This bespoke service ensures that clients receive not just a product, but a precision-engineered solution that maximizes efficiency, reduces operational costs, and guarantees compliance with the most stringent standards.

Real-World Application Case Studies

Our expertise is demonstrated through successful deployments across challenging industrial environments. Here are a few examples of how our Activated Carbon Composite Filter Media delivers tangible results:

-

Case Study 1: Municipal Water Treatment Plant Upgrade

Challenge: A major municipal water utility faced increasing levels of taste- and odor-causing compounds (geosmin, MIB) and disinfection by-products (THMs) in its raw water source, leading to public complaints and compliance issues. Their existing GAC beds were reaching breakthrough too quickly.

Solution: We supplied specialized Activated Carbon Composite Filter Media cartridges, designed for enhanced adsorption kinetics and higher capacity. The composite structure allowed for a higher packing density of activated carbon and reduced channeling.

Result: The plant achieved consistent removal of taste and odor compounds below detection limits, extended filter service life by 30%, and maintained THM levels well within regulatory limits, leading to improved public trust and reduced operational costs from less frequent media replacement. -

Case Study 2: Industrial Wastewater Decolorization in Textile Mill

Challenge: A textile manufacturing facility struggled with highly colored wastewater, containing complex organic dyes, which inhibited biological treatment and prevented discharge compliance.

Solution: We implemented a custom-designed system utilizing our Activated Carbon Composite Filter Media, specifically formulated with a blend of activated carbons optimized for dye adsorption. The filter units were engineered to handle fluctuating flow rates and high organic loads.

Result: The treatment system effectively removed over 95% of color and significantly reduced COD (Chemical Oxygen Demand) from the wastewater, enabling the facility to meet strict discharge regulations and avoid substantial fines. The composite media’s robustness ensured reliable operation in a corrosive environment. -

Case Study 3: Solvent Vapor Recovery in Pharmaceutical Production

Challenge: A pharmaceutical plant needed to recover valuable solvent vapors (e.g., ethanol, acetone) from exhaust air streams to reduce emissions and minimize solvent losses. Traditional systems had high pressure drop and frequent regeneration cycles.

Solution: Our engineering team designed a recovery system incorporating bespoke Activated Carbon Composite Filter Media units. These units featured a low-pressure drop design combined with highly active carbon for efficient solvent adsorption.

Result: The system achieved an average solvent recovery efficiency of over 90%, significantly reducing both operational costs and environmental emissions. The composite media’s stable performance contributed to less frequent regeneration, improving energy saving and overall system uptime.

Ensuring Trust and Support: Our Commitment to Clients

At FiltersMaterial, our commitment extends beyond delivering a superior activated carbon filter for sale. We build lasting partnerships based on trust, transparency, and unwavering support.

- Authoritative Certifications: We are proud to operate under ISO 9001:2015 certified quality management systems, ensuring that every product, including our Activated Carbon Composite Filter Media, meets the highest international standards for quality and consistency. Our products regularly undergo third-party testing to validate performance claims.

- Warranty Commitments: All our Activated Carbon Composite Filter Media products come with a comprehensive warranty against manufacturing defects and for guaranteed performance under specified operating conditions. Details are provided with each quotation and order.

- Lead Time & Fulfillment: With strategically located manufacturing and distribution centers, we offer competitive lead times. Standard products are often available for immediate dispatch, while custom solutions typically follow a clearly communicated production schedule, ranging from 4-8 weeks depending on complexity. Our logistics team ensures efficient and reliable global delivery.

- Dedicated Customer Support: Our team of experienced technical engineers is available to provide pre-sales consultation, system design assistance, installation guidance, and post-sales troubleshooting. We offer remote support, on-site visits, and performance monitoring services to ensure optimal filter operation throughout its lifespan. Reach us via phone, email, or our online portal.

Frequently Asked Questions (FAQ) about Activated Carbon Filters

-

Q: How do I know when my activated carbon filter needs to be replaced?

A: The most common indicator is contaminant breakthrough, where the unwanted substance (e.g., chlorine taste, odor, specific VOCs) begins to be detected in the treated effluent. Monitoring breakthrough curves, pressure drop across the filter, and a predefined service life schedule are also critical. -

Q: What is the difference between physical and chemical adsorption?

A: Physical adsorption (physisorption) involves weak intermolecular forces (van der Waals forces) between the contaminant and the carbon surface. Chemical adsorption (chemisorption) involves a chemical reaction between the contaminant and the carbon surface, often involving impregnated activated carbon, leading to stronger bonds. -

Q: Can activated carbon filters remove all contaminants?

A: No. While highly effective against organic compounds, chlorine, and some heavy metals, activated carbon is generally ineffective at removing dissolved inorganics like sodium, nitrates, or hard water minerals. It also has limited capacity for very small molecules like ammonia unless specifically impregnated. -

Q: What factors influence the service life of an activated carbon filter?

A: Key factors include the type and concentration of contaminants, flow rate, temperature, pH, competing adsorbates, and the quality and type of activated carbon filter media itself (e.g., Iodine Number, surface area). -

Q: Are activated carbon filters environmentally friendly?

A: Yes, in many aspects. The raw materials (e.g., coconut shells) can be renewable. Spent activated carbon can often be reactivated through thermal regeneration, extending its lifecycle and reducing waste. Our composite media is designed for longevity, further reducing environmental impact.

Conclusion

The search for an optimal activated carbon filter for sale is a critical decision for any industrial operation committed to purity, efficiency, and environmental responsibility. Our Activated Carbon Composite Filter Media embodies the pinnacle of filtration technology, offering unparalleled performance through meticulous manufacturing, rigorous testing, and a deep understanding of diverse application demands. Partnering with a supplier that provides not just products, but comprehensive expertise, customization, and unwavering support, ensures that your filtration challenges are met with robust, cost-effective, and sustainable solutions.

References

- Marsh, H., & Rodriguez-Reinoso, F. (2006). Activated Carbon. Elsevier.

- American Society for Testing and Materials (ASTM) International Standards for Activated Carbon.

- International Organization for Standardization (ISO) Standards for Quality Management and Environmental Management.

- United States Environmental Protection Agency (U.S. EPA) Publications on Water and Air Purification Technologies.

- Crittenden, J. C., Hand, D. W., Arora, H., & Thacker, K. (1987). Design of multiple-adsorber systems. Journal of Environmental Engineering, 113(4), 494-510.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog