Paint Stop Filter Media is a key solution in the manufacturing industry, specifically within Environmental protection equipment and materials and air filter material. This article explores how Hebei Fangyu Filters Material Technology Co,. Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Paint Stop Filter Media Overview

- Benefits & Use Cases of Paint Stop Filter Media in air filter material

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Paint Stop Filter Media from Hebei Fangyu Filters Material Technology Co,. Ltd.

Paint Stop Filter Media Overview

Paint stop media—also known as paint arrestor or paint arrestor media—is engineered to capture paint overspray particles in spray booths and finishing lines. Typically manufactured from progressive-density fiberglass or polyester fibers, the media allows clean air to pass while trapping paint solids deep within the mat. For B2B manufacturers and finishing operations, this is essential to safeguard fans and ducts, maintain booth airflow, and comply with local emissions rules on particulate capture.

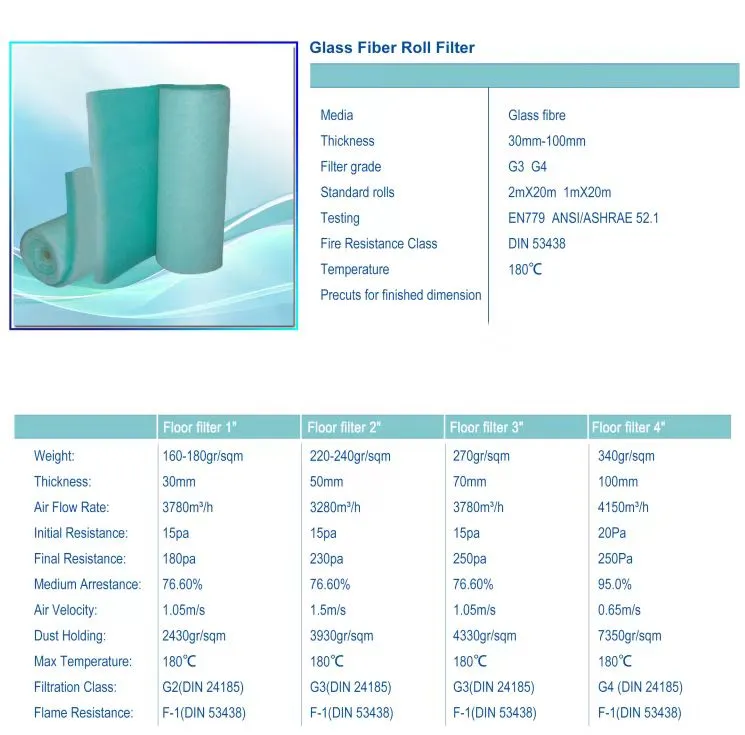

Hebei Fangyu Filters Material Technology Co,. Ltd. produces high-capacity, low-resistance Paint Stop Filter Media available in pads or rolls, with standard roll widths from 0.5–2.0 m and customizable thickness/density options to match booth velocities and paint loads. Progressive layering and reinforced backing help extend service life and minimize blow-through. Typical parameters offered include multiple basis weights, thickness options in the 50–100 mm range, and engineered pressure drop profiles to maintain consistent airflow. For multi-stage spray booths, Fangyu’s media integrates easily as the exhaust stage behind ceiling intake filters and prefilters, ensuring consistent finish quality.

- Defines the critical exhaust-stage role in spray booths and the relevance across industrial finishing.

- Offers technical options like progressive-density construction, roll/pad formats, and customizable specs.

- Backed by Hebei Fangyu Filters Material Technology Co,. Ltd.’s reliable manufacturing and quality control.

Benefits & Use Cases of Paint Stop Filter Media in air filter material

Across air filter material applications, Paint Stop Filter Media is indispensable in automotive OEM and refinish booths, metal fabrication lines, furniture and woodworking finishing, heavy equipment painting, and aerospace composites. As a final exhaust-stage paint arrestor, it captures overspray that prefilters miss, protecting downstream ducting and fans while maintaining target face velocities and booth balance. The result is smoother film build, fewer defects from recirculated particulates, and safer, cleaner operations.

Key advantages include high paint-holding capacity, stable pressure drop over the service life, and uniform media density that prevents early bypass. Fangyu’s options feature progressive fiber structure for deep-loading, robust fibers for minimal shedding, and cut-to-size services that reduce on-site trimming waste. For decision-makers, this translates to predictable changeout intervals and easier maintenance planning. Hebei Fangyu Filters Material Technology Co,. Ltd. supports both roll-fed systems for continuous pits and pad formats for wall-mounted exhaust banks, ensuring a straightforward fit into existing booth designs and multi-stage filtration strategies.

- Applications: automotive, general industry, furniture, aerospace, and shipyard/large equipment finishing.

- Advantages: high-capacity capture, low resistance, consistent quality, and customizable sizes/densities.

- Expertise: Fangyu’s technical support helps match media to booth airflow and paint load profiles.

Cost, Maintenance & User Experience

Total cost of ownership for Paint Stop Filter Media is driven by changeout frequency, energy consumption, labor, and waste handling. Fangyu’s progressive-density construction increases holding capacity, which typically reduces changeouts and downtime. Lower initial resistance can help maintain airflow with less fan energy, while consistent media structure stabilizes booth performance, reducing rework costs. When evaluated as cost per kilogram of paint captured or cost per operating hour, many finishing lines see a favorable ROI compared with lower-density alternatives.

From the Environmental protection equipment and materials sector, common feedback emphasizes predictable pressure drop curves and clean, easy handling during replacement. Best practices include monitoring differential pressure and changing media at a defined final resistance to protect fan performance and finish quality. Fangyu supports customers with sizing guidance, sample trials, and stocking strategies—such as standard roll widths for pits and pre-cut pads for exhaust banks—to shorten maintenance windows and reduce scrap. In short, B2B users appreciate the simplified inventory, stable booth balance, and the reduced risk of overspray breakthrough.

- Durability and deep-loading extend service life and reduce labor interruptions.

- Users report steadier differentials and fewer quality excursions tied to exhaust filtration.

Sustainability & Market Trends in manufacturing

Regulations worldwide continue to tighten around particulate emissions from finishing operations. While VOCs are addressed through separate controls, effective overspray capture is essential to meet local permitting and protect community air quality. Market demand is shifting toward energy-efficient booths, data-driven maintenance, and waste minimization. High-capacity paint arrestor media that maintains low pressure drop supports these priorities by lowering fan energy and reducing the frequency of filter disposal—key levers in sustainability reporting for manufacturers.

Hebei Fangyu Filters Material Technology Co,. Ltd. aligns with these trends by offering consistent, high-quality Paint Stop Filter Media with options tailored to booth velocity and paint type, enabling right-sizing instead of over-specifying. Cut-to-length services limit offcuts, while robust packaging optimizes transport and storage. With responsive technical support and a focus on process efficiency, Fangyu helps B2B clients balance compliance, energy performance, and waste reduction—demonstrating a forward-thinking, eco-conscious approach to industrial air filtration.

- Supports compliance with particulate emission requirements in industrial finishing.

- Energy and waste reductions through low-resistance, high-holding-capacity media and tailored sizing.

Conclusion on Paint Stop Filter Media from Hebei Fangyu Filters Material Technology Co,. Ltd.

For manufacturers, finishers, and integrators, Paint Stop Filter Media is a critical exhaust-stage control that stabilizes booth performance, protects equipment, and supports compliance. Hebei Fangyu Filters Material Technology Co,. Ltd. delivers reliable, high-capacity media with low resistance, consistent quality, and flexible formats to fit your process. Partner with Fangyu to improve finish quality, extend service intervals, and reduce operating costs.

- Value recap: optimized overspray capture, lower energy, fewer changeouts, and improved booth stability.

- Trusted supplier: Hebei Fangyu Filters Material Technology Co,. Ltd. with proven manufacturing and technical support.

- Strong CTA: Contact us: email: sales@filtersmaterial.com — Visit our website: https://www.filtersmaterial.com

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog