A Field Note on Polypropylene Filter Media for Next-Gen Mini-Pleats

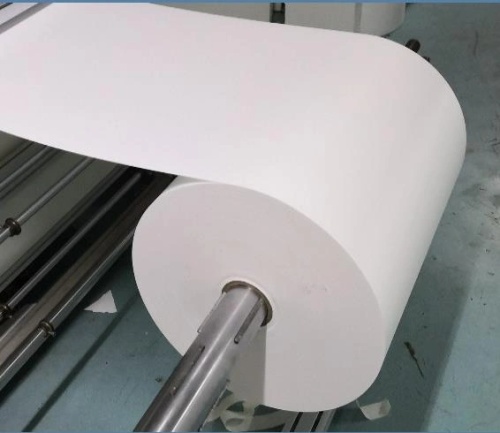

If you’ve spent time around cleanrooms or HVAC retrofits, you know the quiet hero is the media, not the metal frame. Lately I’ve been revisiting laminated composites—PP plus PET—because, to be honest, they’re punching above their weight. The Laminated Composite Filter Media from Handan, Hebei (yes, that Second Building on Shiji Street, I’ve been there) blends polypropylene fibers with PET backing to keep pleats crisp and airflow honest. Many customers say it’s easier to pleat than classic glass. I guess that’s the ultrasonic bonding talking.

Industry Trend Snapshot

Three currents define the moment: energy-efficient upgrades, glass-fiber alternatives (operators prefer skin-friendly media), and faster lead times for mini-pleated modules. In fact, specifiers are pushing for ISO 16890 labeling alongside EN 1822 for higher grades. The result: Polypropylene Filter Media in laminated form is moving from “alternative” to default in M5–H13 builds.

Technical Specs (Real-World Use May Vary)

| Raw Materials | Polypropylene (PP) meltblown + PET support layer |

| Process | Ultrasonic or hot-melt fiber adhesive lamination |

| Efficiency Range | M5–H13 (ISO ePM10/ePM2.5 up to HEPA, per EN 1822/ISO 29463) |

| Basis Weight | ≈ 80–220 g/m² |

| Thickness | ≈ 0.35–0.8 mm |

| Initial ΔP | ≈ 80–180 Pa @ 0.7 m/s (MPPS conditions differ) |

| Heat/Humidity | Up to 70–80°C; RH up to 95% (non-condensing) |

Why ops teams like it: easy pleating, stable geometry, low resistance, and—surprisingly—less media breakage during auto-pleat runs. Polypropylene Filter Media also sidesteps glass fiber handling issues.

Process Flow (How It’s Made)

- Materials: graded PP meltblown web + PET substrate rolls.

- Methods: ultrasonic bonding or hot-melt fiber adhesive; calendering for flatness.

- Mini-pleat forming: bead or continuous hot-melt separators.

- Testing: ISO 16890 for general HVAC; EN 1822/ISO 29463 for H-class; GB/T 14295 for quality; optional UL 900 for flammability.

- Service life: ≈ 6–18 months in HVAC; HEPA use tied to pressure-drop limit or particle count trending.

- Industries: electronics, healthcare, pharma, food & beverage, commercial HVAC, paint lines.

Applications and Advantages

Best suited for mini-pleated panels, V-bank HEPA/ULPA precursors, and compact air handlers where every pascal counts. Advantages: high intensity (stiffness), highest efficiency within class, and lowest resistance vs. many legacy stacks. Field techs tell me it “just pleats cleaner.”

Vendor Comparison (Quick Take)

| Vendor | Certs | MOQ | Lead Time | Customization | Price Band |

|---|---|---|---|---|---|

| Filtersmaterial (Handan, China) | ISO 9001; test to ISO 16890/EN 1822 | ≈ Low | 2–4 weeks | Width, GSM, bonding method | $ |

| Vendor B (EU) | ISO 9001/14001; EN 1822 | Medium | 3–6 weeks | Limited GSM palette | $$$ |

| Vendor C (US) | ISO 9001; UL 900 options | High | 4–8 weeks | Custom slit widths | $$ |

Customization & QA

Options: media width (≤ 1.2–1.6 m), GSM, bonding (ultrasonic vs hot-melt), hydrophobic or antistatic treatments. QA includes MPPS efficiency scans (H grades), gravimetric loading tests, and ΔP drift curves. A recent lot showed 99.95% at MPPS with ΔP ≈ 120 Pa @ 0.7 m/s—nice balance.

Mini Case: Hospital AHU Retrofit

A coastal hospital swapped aging glass-fiber prefilters for Polypropylene Filter Media mini-pleats (ePM1 and H13 finals). Result: blower power dropped ≈ 7–10%, coil fouling slowed, and techs reported fewer media fractures during maintenance. Not earth-shattering, but in tight budgets that matters.

Origin: Second Building and Studying No21 Shiji Street, Handan, Hebei, China.

Final Notes

If you need compact, low-ΔP modules with credible test data, a laminated PP+PET route is hard to ignore. Just specify standards up front and—this is key—align on MPPS testing for H-class lots.

- ISO 16890:2016 Air filters for general ventilation.

- EN 1822-1:2019 High efficiency air filters (EPA, HEPA, ULPA).

- ISO 29463 series High-efficiency filters and filter media.

- GB/T 14295-2019 Air filters—General specification.

- IEST-RP-CC001 HEPA and ULPA Filters; UL 900 (flammability), where applicable.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog