fiberglass filter media,fiberglass filter media rolls,fiberglass air filter media,fiberglass filter material is a key solution in the Environmental Protection Industry industry, specifically within Environmental protection equipment and materials and air filter material. This article explores how Hebei Fangyu Filters Material Technology Co,. Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- fiberglass filter media,fiberglass filter media rolls,fiberglass air filter media,fiberglass filter material Overview

- Benefits & Use Cases of fiberglass filter media,fiberglass filter media rolls,fiberglass air filter media,fiberglass filter material in air filter material

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Environmental Protection Industry

- Conclusion on fiberglass filter media,fiberglass filter media rolls,fiberglass air filter media,fiberglass filter material from Hebei Fangyu Filters Material Technology Co,. Ltd.

fiberglass filter media,fiberglass filter media rolls,fiberglass air filter media,fiberglass filter material Overview

In high-demand HVAC and industrial ventilation systems, fiberglass filter media delivers dependable, mechanical particle capture that remains stable across humidity, temperature swings, and long service intervals. As a lofted, progressively dense mat of fine glass fibers bonded with a durable resin system, fiberglass air filter media is engineered to achieve consistent efficiency and low pressure drop in pocket/bag filters, pleats, and specialty panels. Offered as fiberglass filter media rolls for quick converting, it supports scalable production for OEMs and filter assemblers.

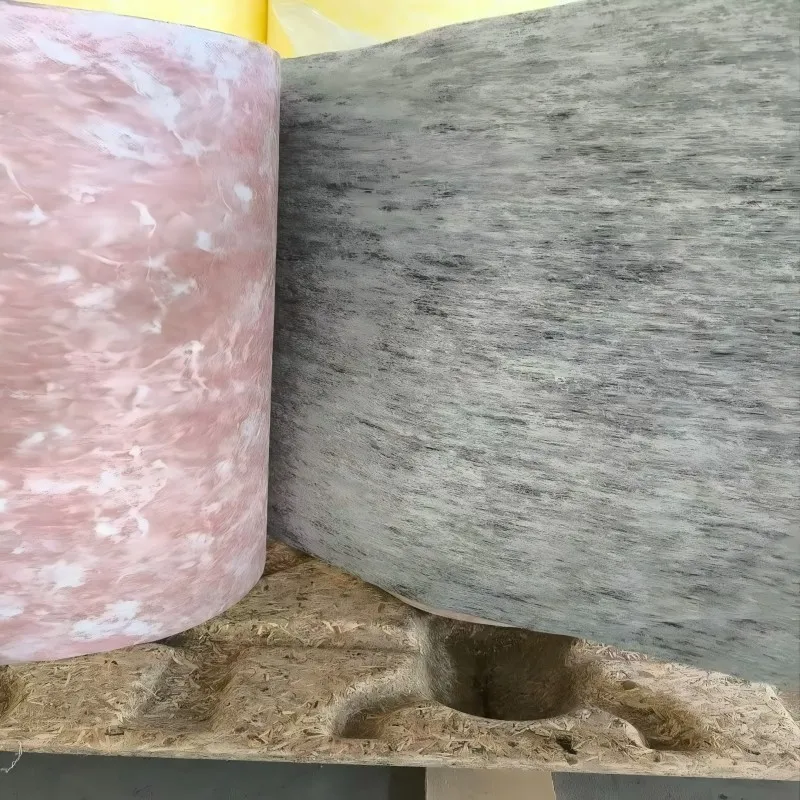

Hebei Fangyu Filters Material Technology Co,. Ltd. manufactures fiberglass filter material with controlled fiber diameter distribution, reinforced scrim options, and uniform basis weight for repeatable performance. Typical efficiency targets align with common HVAC frameworks (e.g., MERV levels in many markets), and color-coded variants help QA teams visually manage grades on the line. Rolls can be supplied in custom widths and lengths to minimize trim waste and maximize throughput. In-house quality testing and traceability programs help ensure each lot meets agreed specifications for resistance, dust holding capacity, and structural integrity—key criteria for B2B buyers who require predictable lifecycle costs and reliable air quality outcomes.

Benefits & Use Cases of fiberglass filter media,fiberglass filter media rolls,fiberglass air filter media,fiberglass filter material in air filter material

For air filter material applications, fiberglass filter media shines in pocket/bag filters used in commercial buildings, industrial ventilation, cleanroom make-up air, automotive paint booths, and turbine/compressor intake prefiltration. Because fiberglass relies on mechanical filtration rather than electrostatic charge, performance remains stable as filters load—supporting consistent capture of fine particles (such as PM2.5) over the full service life. The media’s resilient loft and progressive density construction deliver high dust holding capacity, delaying the rise to final pressure drop and extending changeout intervals.

Hebei Fangyu’s fiberglass filter media rolls are optimized for converting on sewing and ultrasonic lines, with reinforced scrim options for robust pocket formation and dimensional stability in high-airflow housings. Competitive advantages include:

- Stable efficiency across humidity and temperature compared to many electret synthetics

- Low, predictable initial resistance for energy-efficient operation

- Excellent dust holding capacity that supports longer maintenance cycles

- Customizable basis weight and thickness for targeted MERV/ePM outcomes

- Value-add variants, such as fiberglass filter material with an activated carbon layer for odor/VOC control

With deep application knowledge and responsive engineering, Hebei Fangyu Filters Material Technology Co,. Ltd. helps OEMs select the right fiberglass air filter media grade to meet IAQ targets while simplifying production and inventory.

Cost, Maintenance & User Experience

Total cost of ownership for fiberglass filter media is driven by energy usage, service life, and labor. By combining low initial pressure drop with strong dust holding capacity, fiberglass-based pocket filters maintain acceptable resistance longer—reducing changeout frequency, truck rolls, and downtime. For OEMs and large facility operators, fiberglass filter media rolls also compress procurement and production costs by enabling efficient, high-yield converting with minimal scrap.

Maintenance teams value the predictable loading curve and mechanical efficiency of fiberglass air filter media, which avoids performance swings seen in charged synthetics as environmental conditions vary. Best practices include staging with a coarse prefilter in dusty environments, monitoring differential pressure to trigger changeout at the specified final resistance, and storing rolls in clean, dry conditions to preserve loft. Customers in environmental protection equipment and materials report smoother IAQ compliance, fewer nuisance alarms from rising pressure drop, and more consistent airflow delivery to critical spaces such as paint lines and sensitive manufacturing zones.

When assessed over a 12–24 month horizon, the ROI often stems from fewer filter replacements, lower labor hours, and stabilized fan energy. Hebei Fangyu supports TCO optimization via tailored grades that balance efficiency targets with resistance, helping decision makers dial in energy and maintenance savings.

Sustainability & Market Trends in Environmental Protection Industry

Air quality regulations and building standards continue to evolve toward higher particle capture and documented performance, with many markets aligning to frameworks like ISO 16890 and MERV-based guidance. In parallel, energy efficiency mandates push stakeholders to select media that maintains low resistance across the life of the filter—translating into measurable CO₂ reductions at the system level. Fiberglass filter material supports these objectives by providing stable mechanical filtration and long service intervals, thereby reducing material turnover and associated waste.

The Environmental Protection Industry is also seeing wider adoption of data-driven facilities management, where pressure sensors and analytics track filter health to avoid premature changeouts. Hebei Fangyu Filters Material Technology Co,. Ltd. maps its product development to these trends, focusing on consistent lot-to-lot performance, options for extended-life grades, and configurations that integrate adsorptive layers for IAQ challenges beyond particulates. The company’s process control and material selection philosophy emphasize durability and efficiency, aligning with customers’ ESG goals without sacrificing air performance.

Conclusion on fiberglass filter media,fiberglass filter media rolls,fiberglass air filter media,fiberglass filter material from Hebei Fangyu Filters Material Technology Co,. Ltd.

For B2B decision makers in Environmental protection equipment and materials, fiberglass filter media delivers the dependable, mechanical efficiency and long service life needed to meet stricter IAQ targets while controlling operating costs. Supplied as fiberglass filter media rolls and engineered for pocket, pleat, and specialty formats, Hebei Fangyu Filters Material Technology Co,. Ltd. provides consistent quality, strong technical support, and flexible customization to fit your production line and performance goals.

Contact us: email: sales@filtersmaterial.com

Visit our website: https://www.filtersmaterial.com

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog