Expanded Metal Mesh for Air Filters: what’s new, what works, what to watch

If you build or buy air filters, you’ve likely touched

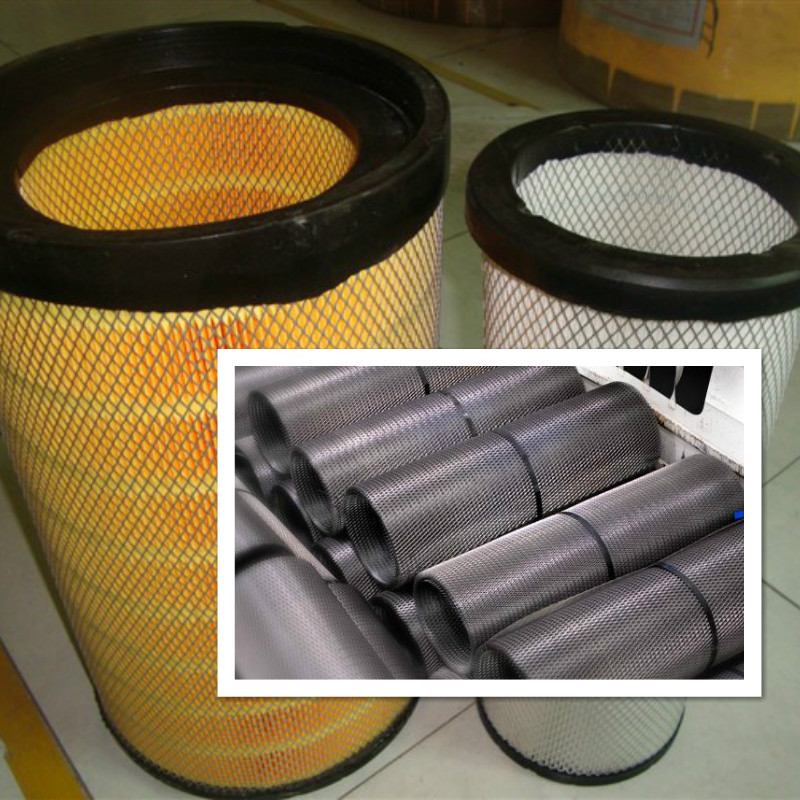

Expanded Metal Mesh For Air Filters

without thinking twice. It quietly does the hard job: supporting pleats, protecting media from bumps, and keeping pressure drop honest. Lately, demand is up across HVAC, paint booths, and compressor intakes—partly driven by tighter energy targets and the push to extend filter life.

Industry snapshot

To be honest, the trend is toward lighter gauges with smarter coatings. Galvanized steel still dominates, but aluminum is picking up where corrosion is brutal or weight is critical. Many customers say they’re standardizing on narrower SWD for better pleat stability—surprisingly, it can shave a few Pascals of initial resistance when matched correctly to the media.

Core specs (real-world ranges)

| Thickness | 0.2–6 mm (≈), customizable |

| Strand Thickness | 0.5–8 mm (typical filter support: 0.3–0.8 mm) |

| SWD / LWD | SWD 2.5–100 mm; LWD 4.5–200 mm |

| Materials | Low-carbon steel, galvanized steel, Al 3003/5052, SS304/316 |

| Surface | Galvanized, powder coated (60–90 μm ≈) |

| Open Area | 30–70% (depends on SWD/LWD) |

Process flow and QC (how it’s actually made)

- Materials: coil-fed low-carbon steel or aluminum; optional SS for harsh chem.

- Expansion: slitting-and-stretching on press; then flattening (when required).

- Finishing: galvanizing or powder coating; edge trimming; cut-to-size or rolls.

- Testing: ASTM F1267 dimensional checks; burr limits; zinc thickness via coating gauge; salt spray per ISO 9227/ASTM B117.

- Integration test: pressure drop with media per ISO 16890 rig; mesh stiffness vs pleat collapse.

- Service life: ≈5–10 years as a support layer in indoor HVAC; outdoors may vary.

Where it’s used

HVAC bag and box filters, turbine/compressor intake prefilters, automotive cabin modules, spray booth prefilters, food & pharma make-up air (with coated or SS mesh). In cleanrooms, Expanded Metal Mesh For Air Filters stabilizes mini-pleats without cutting fragile media.

Advantages (from field notes)

- Rigid support with low added ΔP; open area tuned to media.

- Better pleat uniformity; fewer “hot spots” under airflow surges.

- Coatings resist corrosion; powder coat also tames sharp edges—operators appreciate that.

Vendor snapshot (indicative, real-world may vary)

| Vendor Type | Lead Time | Certs | Notes |

| Mill + Coater (China) | 2–4 weeks | ISO 9001, RoHS | Best for custom SWD/LWD and color coats. |

| Regional Fabricator | 1–2 weeks | ISO 9001 | Fast cuts-to-size; fewer alloy options. |

| Import Broker | 4–8 weeks | Varies | Price-driven; watch tolerances and coatings. |

Customization tips

For Expanded Metal Mesh For Air Filters, match SWD to pleat pitch; keep open area ≥50% for high-MERV media. In corrosive zones, pick Al 5052 or SS316; otherwise galvanized steel with ≥70 μm zinc equivalent is a pragmatic balance. Powder coat helps assembly safety and color coding.

Quick case notes

- Paint shop prefilters: galvanized mesh with SWD 5 mm cut ΔP by ≈6–8 Pa vs legacy guard; 480 h salt spray, no red rust.

- Hospital AHU: powder-coated Al mesh stabilized mini-pleat; HEPA integrity held after 10 start/stop cycles per UL 900 test rig.

- Mining compressor intake: SS304 mesh survived abrasive dust; pleat collapse incidents dropped to zero in 90 days.

Compliance, test data, and origin

Typical tests: ISO 16890 pressure drop mapping; ASTM B117 or ISO 9227 salt spray (≥240–500 h for coated steel); dimensional checks per ASTM F1267; flammability per UL 900 (assembly level). Origin for the product featured here: Second Buliding and Studying No21 shiji street, Handan, Hebei China.

References

- ASTM F1267 – Standard Specification for Expanded Metal.

- ISO 16890 – Air filters for general ventilation.

- ASTM B117 / ISO 9227 – Salt Spray (Fog) Testing.

- UL 900 – Standard for Air Filter Units.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog