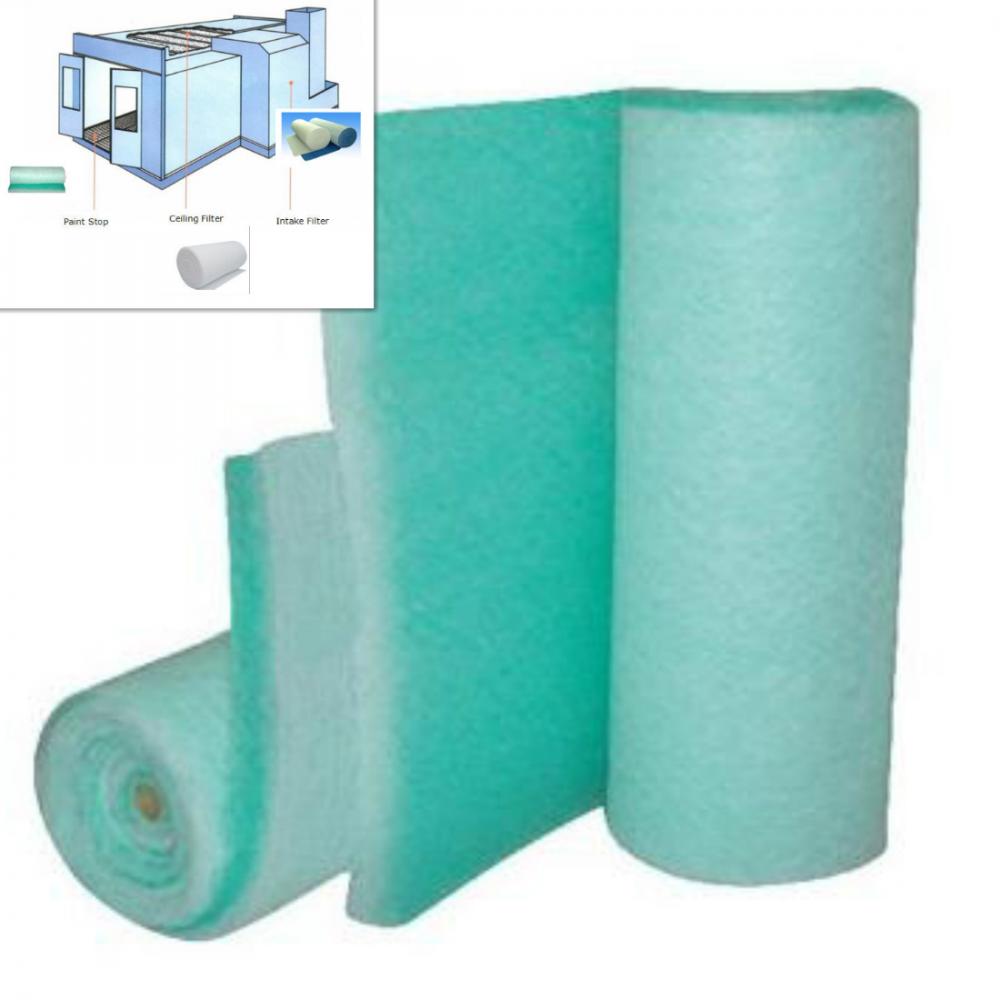

If you spend any time around paint lines or body shops, you know the consumable that quietly makes or breaks finish quality: Paint Stop Filter Media. I’ve stood in booths where the floor looked like confetti and yet the finish came out glassy—usually because the media was sized and installed right. This piece pulls together what’s working in the market, what to spec, and how shops are actually using it.

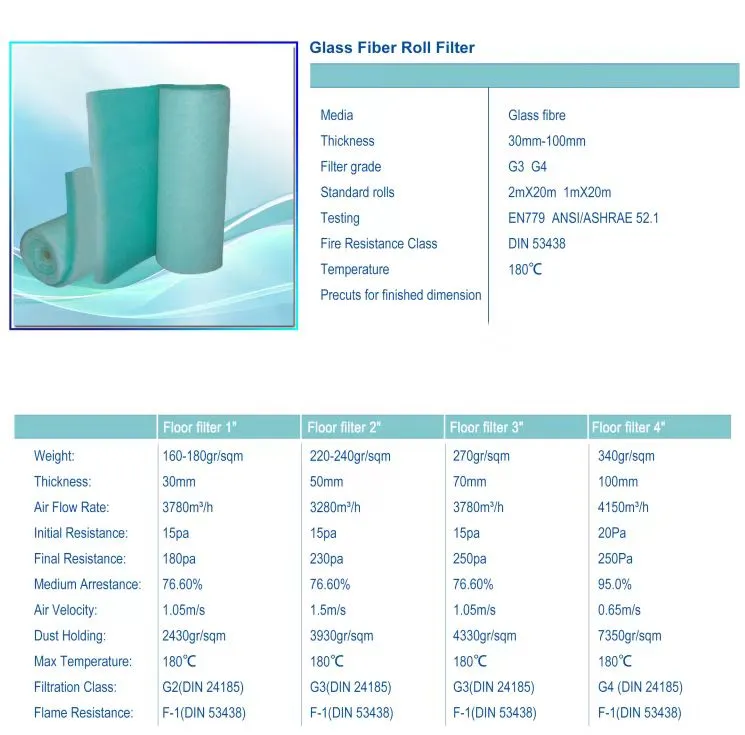

Product snapshot (origin: Second Buliding and Studying No21 shiji street, Handan, Hebei China): glass-fiber arrestor mat, thickness ≈30–100 mm, filter grades G3–G4 (legacy EN 779), standard rolls 2 m × 20 m or 1 m × 20 m, temperature resistance up to 180°C, fire class per DIN 53438. Many customers say it’s a “set and forget” layer for overspray capture—until it’s saturated, of course.

Why shops still choose Paint Stop Filter Media

- Progressive-density glass fiber traps coarse overspray up front, finer particles deeper in the mat.

- Low initial resistance keeps booth airflow stable; painters actually feel the difference.

- Fire performance per DIN 53438; compatible with both solvent- and waterborne coatings.

- Roll formats cut-to-size; easy pad changes reduce downtime. Simple is underrated.

Key specifications

| Media | Glass fiber, progressive density |

| Thickness | ≈30–100 mm (real-world use may vary by batch) |

| Grade | G3–G4 (EN 779 legacy); roughly coarse class under ISO 16890 |

| Roll sizes | 2 m × 20 m; 1 m × 20 m (standard) |

| Temp limit | Up to 180°C |

| Fire class | DIN 53438 |

| Initial resistance | ≈8–25 Pa at 0.7–1.5 m/s |

| Overspray arrestance | ≈96–99% (application-dependent) |

| Service life | Typically 1–4 weeks in body shops; check pressure rise or visual loading |

How it’s made and tested

Materials: random-laid glass fibers with a light resin binder. Process: fiberizing, layering for progressive density, thermal curing, then slitting and rolling. QC: thickness and weight checks; airflow and resistance; arrestance vs synthetic dust (per EN 779 legacy/ASHRAE methodologies); flame behavior per DIN 53438. In fact, some vendors also cross-check against ISO 16890 coarse metrics for consistency.

Where it’s used

- Automotive refinish booths and prep stations

- Industrial finishing: metal parts, appliances, rail, aerospace, marine

- Wood finishing lines (varnish, lacquer, waterborne)

Case notes: a Tier-2 metal finisher cut booth downtime 18% by switching to thicker Paint Stop Filter Media in high-load zones; a body shop chain reported fewer nib defects and steadier airflow after tightening pad change intervals to 2 weeks. Honestly, it’s usually the schedule, not the media, that drifts.

Vendor snapshot and customization

Customization typically includes roll width, pad pre-cuts, and thickness selection. Some facilities mix grades: G4 ceiling intake + thick booth-floor Paint Stop Filter Media to balance airflow and arrestance.

| Vendor | Thickness range | Certs/claims | Lead time | Notes |

| FiltersMaterial (Hebei) | ≈30–100 mm | DIN 53438; EN 779 G3–G4 | ≈7–15 days | Standard 2×20 m and 1×20 m rolls |

| Vendor A (EU) | ≈50–75 mm | ISO 16890 coarse reference | ≈10–20 days | Pre-cut pad service |

| Vendor B (US) | ≈25–100 mm | ASHRAE test data | Stock-dependent | OEM booth kits |

Practical tips (learned the hard way)

- Track pressure rise; swap media when ΔP increases ≈2–3× from clean, or when surface visibly skins over.

- Seal edges and seams—leakage around great media is still lousy filtration.

- Match thickness to paint load: heavy primer days = thicker mat or more frequent changeouts.

Citations

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog