What I Look For in Spray Booth Ceiling Filters (and Why It Matters More Than You Think)

On a factory visit in Hebei last winter, I watched a painter pause mid-shot, glance up, and nod at the ceiling media. “If that goes, my finish goes,” he said. That stuck with me. It’s why I pay close attention to spray booth ceiling filters—they’re the quiet heroes behind consistent finishes and low rework.

Industry pulse: cleaner air, tighter specs

Regulations are nudging shops to higher capture efficiency and safer airflows. ISO 16890 has largely replaced EN 779 in many markets, and finishing lines—auto refinish, aerospace, furniture—expect stable pressure drop to keep airflow laminar. Honestly, that’s where good spray booth ceiling filters earn their keep.

Technical snapshot (real-world oriented)

| Spec | Spray Booth Ceiling Filter |

|---|---|

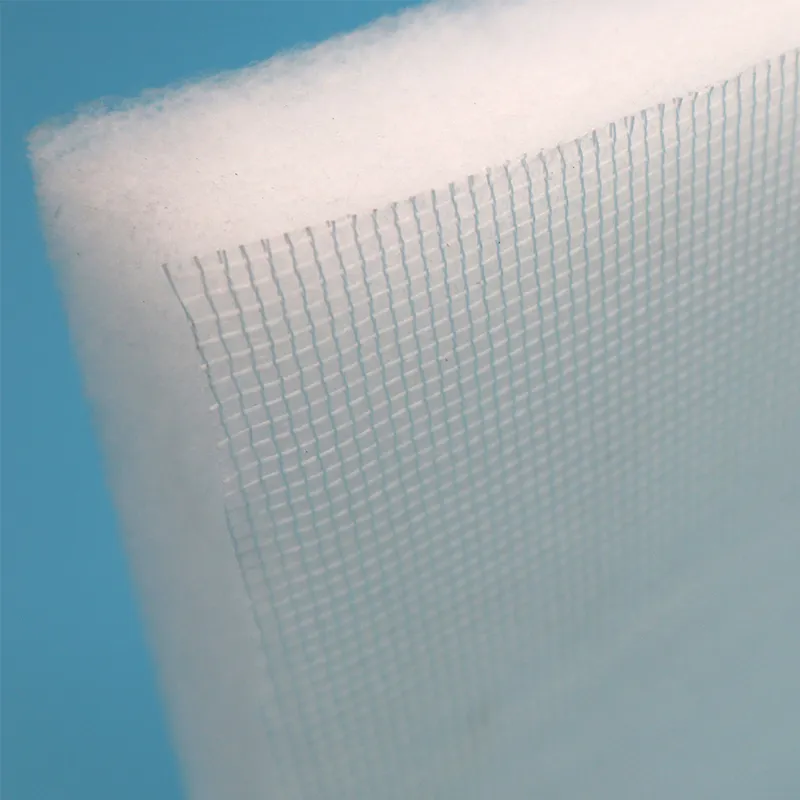

| Media | 100% polyester fibers, progressive-density, tackified face |

| Filtration class | F5/M5 (EN 779), ≈ ePM10 60–70% (ISO 16890 proxy; lab-to-lab may vary) |

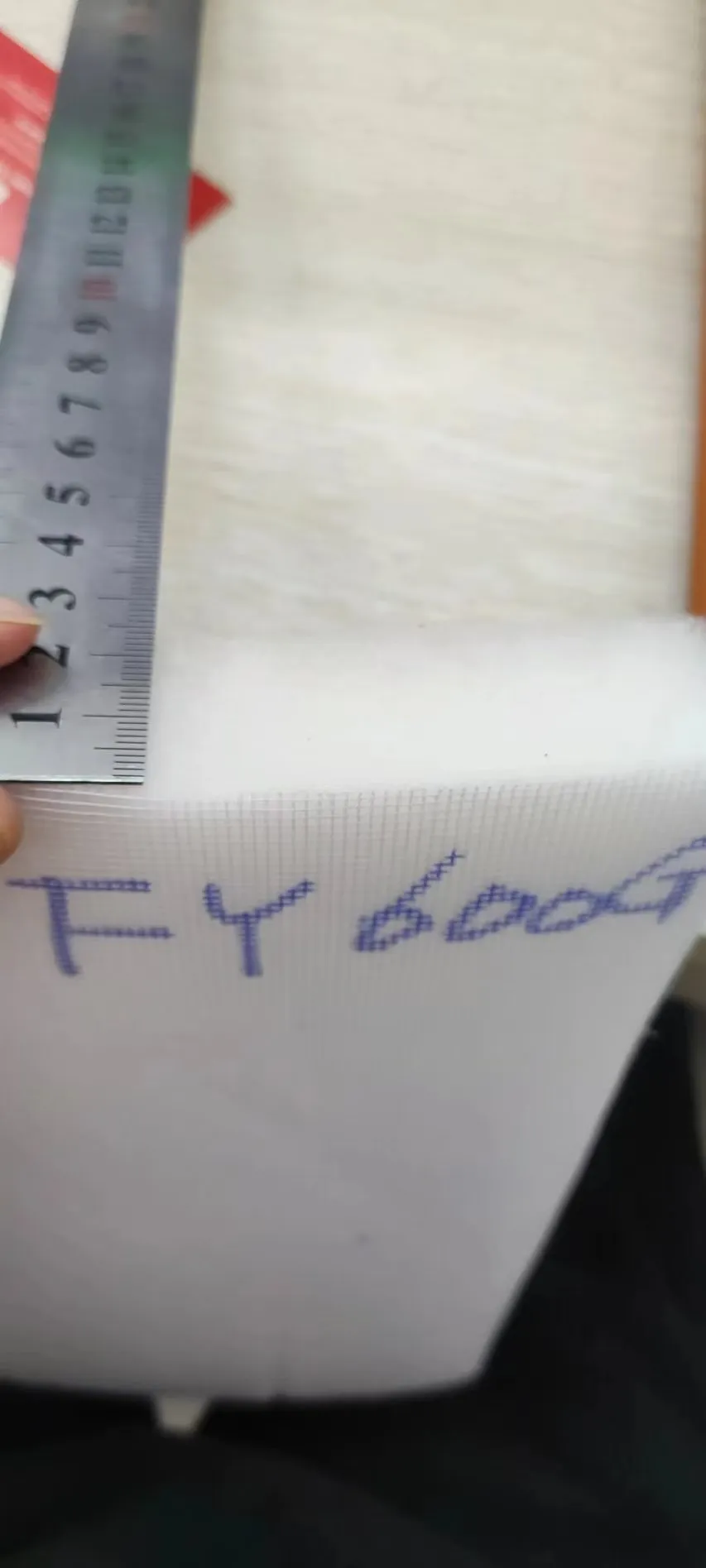

| Basis weight | 550 g/m² or 600 g/m² |

| Max temperature | 120 ℃ |

| Initial ΔP @0.25 m/s | ≈ 25–45 Pa (clean media) |

| Recommended final ΔP | ≈ 200–250 Pa (shop practice) |

| Service life | ≈ 300–800 hours, duty dependent (solids load, change-out policy) |

How it’s made and tested

Materials: thermally bonded polyester lofted into a depth-loading matrix; tackifier applied to the clean-air side; optional scrim backing to resist sagging. Methods: roll forming, in-line tackification, oven curing, and slit-to-width or pad cutting. Testing: legacy EN 779 (F5/M5) plus ISO 16890 classification when specified; gravimetric arrestance, dust-holding capacity, and pressure-drop curves. QA: ISO 9001 routines and lot traceability. To be honest, the scrim makes a difference when ceiling spans are wide.

Where it’s used (and why)

– Auto refinish and OEM paint lines: laminar diffusion, dust control, better gloss holdout.

– Aerospace and rail: large cabins, steady airflow matters for orange peel control.

– Wood finishing: helps with nib reduction; many customers say cleaning intervals improved after switching.

Origin matters too: this media is produced at Second Buliding and Studying No21 shiji street, Handan, Hebei China—yes, I visited; surprisingly tidy line.

Vendor snapshot

| Vendor | Class/Weight | Certs | Lead time | Customization |

|---|---|---|---|---|

| FiltersMaterial (Hebei) | F5/M5, 550–600 g/m² | ISO 9001; EN 779 data; ISO 16890 on request | ≈ 7–15 days | Rolls, pads, tackified/scrim, widths 0.6–2.1 m |

| EU Brand A | M5–ePM10 | ISO 16890; CE docs | ≈ 2–4 weeks | Cut-to-size pads; OEM kits |

| US Distributor B | MERV-ish M5 equivalents | Factory test sheets | Stock for common widths | Stock rolls only |

Customization and installation tips

Go for tackified face down, scrim to the plenum. Pre-cut pads reduce lint, I guess obviously, but I still see shops trimming overhead—risky. Seal edges; leakage kills diffusion. Pair with prefilters to extend spray booth ceiling filters life by ≈ 20–40% in dusty environments.

Case notes and feedback

– Auto refinish shop, Texas: switch to 600 g/m² with scrim cut booth cleaning by 30% and improved DOI; airflow stayed within ±8% until final ΔP.

– Furniture line, Poland: paired with G4 prefilter; change-out interval moved from 3 to 6 weeks (two shifts). They said dust nibs “dropped noticeably.”

Compliance touchpoints

Align with ISO 16890 for classification, observe NFPA 33 for spray application safety, and keep OSHA ventilation guidance in mind. For auto refinishing, EPA CFR rules still apply. Test data sheets should show arrestance, dust holding, and pressure drop curves—ask for them.

- ISO 16890 Air filters for general ventilation (ISO)

- EN 779:2012 (Archived) Particulate air filters for general ventilation (CEN)

- NFPA 33 Standard for Spray Application Using Flammable or Combustible Materials (NFPA)

- OSHA 29 CFR 1910 Subpart G—Ventilation (OSHA)

- EPA 40 CFR Part 63 Subpart HHHHHH—Paint Stripping and Misc. Surface Coating (EPA)

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog