melt blown filter media, meltblown filter material, melt blown filter manufacturers, meltblown media is a key solution in the new materials industry industry, specifically within Polymer materials and products and Manufacturing of high-performance filter materials. This article explores how Hebei Fangyu Filters Material Technology Co,. Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- melt blown filter media,meltblown filter material,melt blown filter manufacturers,meltblown media Overview

- Benefits & Use Cases of melt blown filter media,meltblown filter material,melt blown filter manufacturers,meltblown media in Manufacturing of high-performance filter materials

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in new materials industry

- Conclusion on melt blown filter media,meltblown filter material,melt blown filter manufacturers,meltblown media from Hebei Fangyu Filters Material Technology Co,. Ltd.

melt blown filter media,meltblown filter material,melt blown filter manufacturers,meltblown media Overview

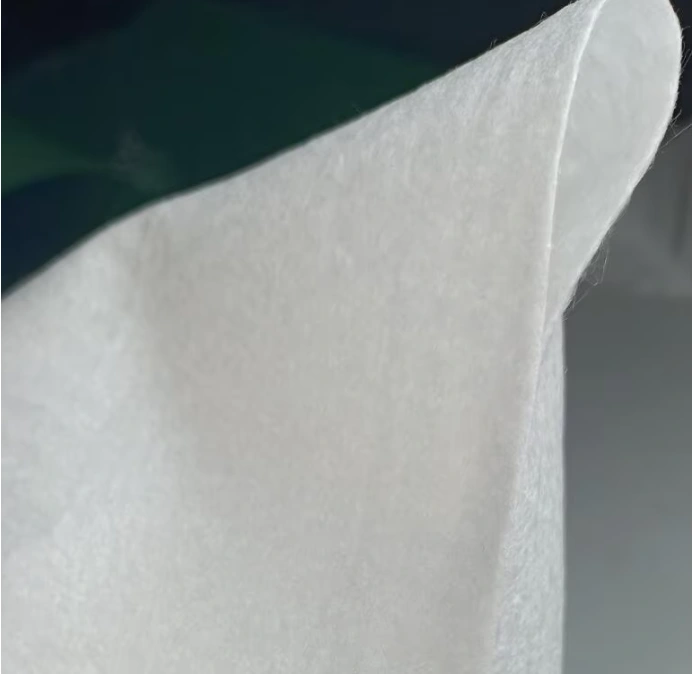

In high-performance filtration, melt blown filter media—also called meltblown media—is engineered from thermoplastic polymers (typically polypropylene) extruded through micro-orifices and attenuated by hot air to form ultra-fine fibers. The resulting web delivers high surface area, narrow pore size distribution, and excellent particulate capture at low pressure drop. Typical technical parameters include basis weight ranging from ~10–300 gsm, fiber diameters in the 1–5 μm range, and customizable efficiencies for key particle sizes. Electret charging can further boost capture of submicron particles while preserving airflow.

Hebei Fangyu Filters Material Technology Co,. Ltd. designs and manufactures meltblown filter material and composite constructions (e.g., meltblown + spunbond, or synthetic multilayers) to match targeted performance needs across HVAC, industrial dust control, and clean-process applications. Options include tailored roll widths, core IDs, calendering, thermal bonding, and multilayer lamination for strength and dust holding. For teams benchmarking melt blown filter manufacturers, Fangyu’s process control and consistent resin selection help ensure uniform media formation and repeatable quality. Explore the full range and specifications here: meltblown filter material product page.

Benefits & Use Cases of melt blown filter media,meltblown filter material,melt blown filter manufacturers,meltblown media in Manufacturing of high-performance filter materials

Across Manufacturing of high-performance filter materials, melt blown filter media stands out for combining efficiency with energy-saving airflow. In HVAC and air purification, engineered grades can be configured to meet common market frameworks (e.g., ISO 16890/MERV targets) with balanced pressure drop and extended dust holding. In industrial filtration—compressor intakes, process ventilation, and dust collection—robust composite structures pair meltblown capture layers with spunbond backing for pleatability and mechanical strength. For clean-process sectors such as electronics, pharma, and food and beverage, high-efficiency meltblown media supports stringent particulate control when designed into multi-stage systems.

Hebei Fangyu’s meltblown media portfolio emphasizes uniform fiber laydown, electrostatic charge stability, and tailored porosity to maintain efficiency over service life. Advantages include consistent basis weight (tight CV%), high loft for contaminant storage, and compatibility with thermal and ultrasonic bonding. The result is durable, pleatable media suitable for panel, pocket, and cartridge geometries. When selecting among melt blown filter manufacturers, B2B buyers value Fangyu’s application engineering support—helping convert performance targets (efficiency, ΔP, dust holding, and service interval) into an optimal media recipe that accelerates qualification and time-to-market.

Cost, Maintenance & User Experience

Total cost of ownership in filtration is driven by media efficiency stability, pressure drop, and service interval. Meltblown filter material from Hebei Fangyu is designed to provide a favorable balance: high initial and operational efficiency with low resistance, which can help reduce fan energy draw and extend changeout intervals depending on system sizing and load profiles. In multi-layer composites, the meltblown layer captures fine particulates while upstream/downstream supports enhance rigidity and dust holding, minimizing premature clogging.

B2B customers in the Polymer materials and products sector report smoother downstream converting—less web breakage, consistent pleat height, and predictable bonding—translating to fewer line stoppages and reduced scrap. Maintenance teams note more stable ΔP growth curves, facilitating planned service rather than reactive changeouts. From an ROI perspective, the combination of energy efficiency, longer media life in properly designed systems, and reliable convertibility often outweighs unit price deltas. Hebei Fangyu backs this with application guidance, test data support, and pilot rolls to streamline validation and reduce commercialization risk.

Sustainability & Market Trends in new materials industry

The new materials industry is moving toward cleaner production, circularity, and data-backed performance. For melt blown filter media, this means optimizing polymer selection, reducing waste, and maximizing filter life to minimize environmental footprint per unit of clean air delivered. Regulations and frameworks such as ISO 16890 for general ventilation, EN 1822 for EPA/HEPA/ULPA classification, and various regional guidelines continue to shape media design toward verifiable, in-use performance—encouraging balance between efficiency and energy consumption.

Hebei Fangyu Filters Material Technology Co,. Ltd. invests in process control and resource efficiency—targeting reduced off-spec scrap, reclaiming suitable post-industrial materials where appropriate, and implementing cleaner thermal processes inherent to meltblowing (no solvent phase). Market trends include higher-efficiency grades for compact equipment, composite architectures for extended dust holding, and growing demand in electronics and life sciences. Fangyu’s forward-thinking development pipeline focuses on consistent electret performance, durable charge retention, and media engineered for longer service life, aligning product innovation with customers’ ESG and operational goals.

Conclusion on melt blown filter media,meltblown filter material,melt blown filter manufacturers,meltblown media from Hebei Fangyu Filters Material Technology Co,. Ltd.

Meltblown media is central to modern air and process filtration, enabling high efficiency at low pressure drop for HVAC, industrial, and clean-process markets. Hebei Fangyu Filters Material Technology Co,. Ltd. delivers melt blown filter media and composite solutions that help B2B decision makers achieve dependable performance, efficient converting, and favorable TCO. Partner with a manufacturer that aligns engineering expertise with your application requirements.

Contact us: email: sales@filtersmaterial.com

Visit our website: https://www.filtersmaterial.com

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog