Laminated Air Filter Media With Mesh: What Matters Now, What Works in the Field

If you work around HVAC or process air, you already know the stakes. The first time I handled filter media laminated to metal mesh, I thought: finally, a pre-filter that stays rigid when the fan curve misbehaves. Made in Handan, Hebei, this polyester-based roll stock shows up in real plants—not just catalogs.

Industry trends (short version)

ISO 16890 replaced EN 779 (yes, for good), and ASHRAE MERV ratings still rule North American specs. Plants want lower ΔP to cut energy, better ePM1 capture for PM2.5, and—surprisingly—more rugged filter media that won’t collapse under humid start-ups. Polyester with expanded metal lamination is back in vogue because it pleats cleanly and keeps shape.

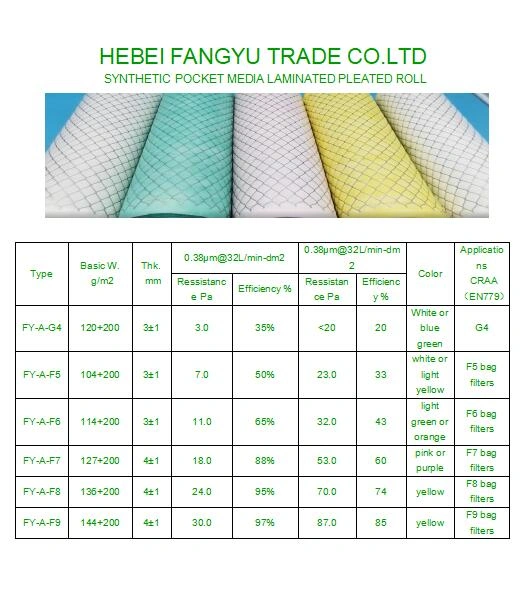

Key specifications at a glance

| Media | 100% polyester fibre, laminated with metal mesh |

| Efficiency | G3–F9; MERV5–MERV14 (real-world use may vary) |

| Colors | White, Blue, Green, Pink, Yellow |

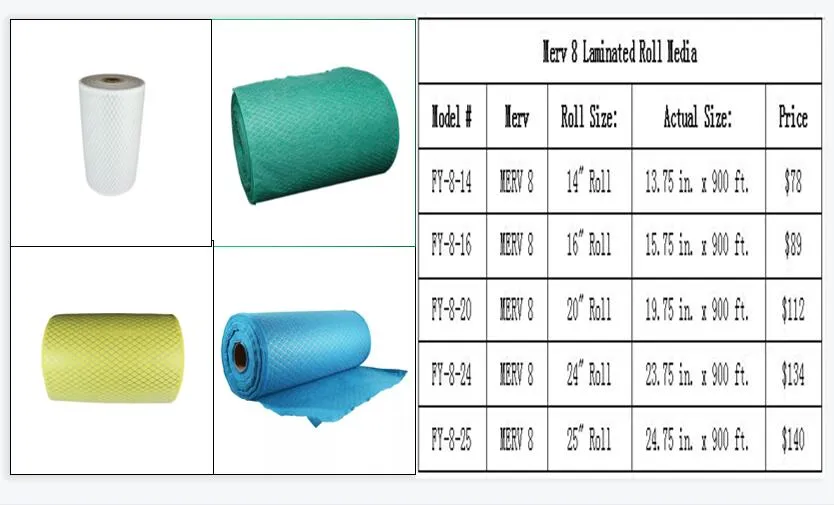

| Widths | 20”, 16”, 18”, 24”, 25” (custom on request) |

| Max temperature | ≈80℃ continuous |

| Initial ΔP (MERV8) | ≈45–70 Pa @ 2.54 m/s, depending on pleat geometry |

| Dust holding | High, aided by progressive density fibre web + mesh support |

| Compliance | Tested to ASHRAE 52.2 / ISO 16890; UL 900 Class 2 typical |

How it’s made (short process flow)

- Materials: thermally bonded polyester fibre web + expanded metal (or wire) mesh.

- Methods: carding → layering → thermal bonding → lamination to mesh → calendering → slitting to width → roll or pad conversion.

- Testing: ASHRAE 52.2 (MERV), ISO 16890 (ePM ratings), ΔP curves, dust-loading; optional UL 900, ISO 846 (microbial).

- Service life: typically 3–12 months; to be honest, load profiles vary wildly by site.

- Industries: commercial HVAC, hospitals, food, automotive paint, electronics, schools, airports.

Why operators pick this filter media

- Rigid under flow spikes; mesh prevents pleat flutter.

- Consistent efficiencies from G3 to F9 / MERV5–14.

- Color coding helps maintenance sort stages fast.

- Cut-to-width convenience and predictable ΔP.

Vendor comparison (quick, practical)

| Vendor | Range | Mesh | Lead time | Certs | Notes |

|---|---|---|---|---|---|

| FiltersMaterial (Handan) | G3–F9 / MERV5–14 | Expanded metal / wire | ≈2–4 weeks | ISO 9001, UL 900 | Color-coded, custom widths |

| Vendor A | MERV7–13 | Expanded metal | 3–6 weeks | UL 900 | Limited colors |

| Vendor B | G4–F7 | Wire mesh | ≈4 weeks | ISO 9001 | Economy-focused |

Applications I keep seeing

- Pre-filters in rooftop units, AHUs, and make-up air systems.

- Paint booths (auto and metal fab) where overspray demands steady airflow.

- Hospital and school intakes before bag or HEPA stages.

Customization (the practical bits)

Widths (16–25” standard, custom on request), roll length, color coding, mesh type, target MERV, and private label. Many customers say pad pre-cuts save 20–30 minutes per changeout—feels about right.

Two quick field notes

- Hospital intake (MERV13/F7): PM2.5 down ≈42% at stage 1, coil ΔP stabilized; changeout extended from 8 to 11 weeks. Staff liked the stiffer filter media.

- Auto paint line (MERV8/F5): Overspray capture up, rework rate down ≈8%. The mesh kept pleats from “smiling” during purge cycles.

Standards and data you can ask for

Request ASHRAE 52.2 reports (MERV, arrestance), ISO 16890 ePMx data, ΔP vs. face velocity curves, UL 900 flame rating, and if you’re cautious about microbes, ISO 846 notes. I guess it sounds formal, but having the paperwork ready really shortens approvals.

Bottom line

For pre-filtration where rigidity, sane ΔP, and predictable MERV matter, this laminated polyester filter media is a solid, no-drama choice. Origin: Second Building and Studying No21 Shiji Street, Handan, Hebei, China—worth noting for logistics planning.

Authoritative references

- ISO 16890-1:2016, Air filters for general ventilation.

- ASHRAE Standard 52.2-2017, Method of Testing General Ventilation Air-Cleaning Devices.

- EN 779:2012 (superseded by ISO 16890) — historical reference for G-class/F-class.

- UL 900, Standard for Air Filter Units (Flammability).

- ISO 846:2019, Evaluation of the action of microorganisms on plastics.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog