A Field Guide to Paint Spray Booth Filter Media (from someone who’s spent too long in finishing rooms)

If you run a spray booth, you’ve certainly wrestled with overspray, booth downtime, and the delicate balance between airflow and capture efficiency. The unsung hero here is the paint stop filter media. And to be honest, the market has shifted fast—better binders, tighter specs, more third‑party testing. Below is what I’m seeing right now, plus real numbers from shop floors.

What it is and why it works

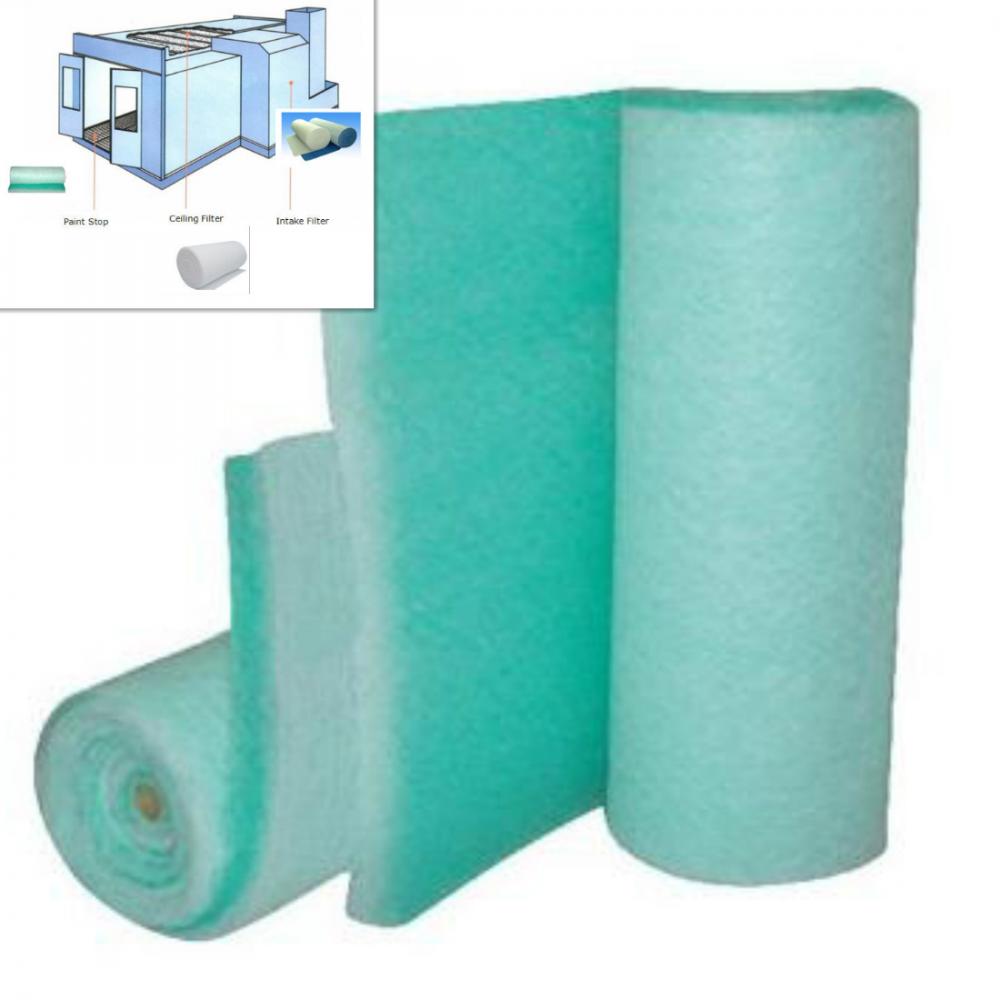

This product—often called green/white glass-fiber arrestor—uses progressive-density glass fibers to trap wet overspray while keeping pressure drop reasonable. Actually, that density gradient is the trick: paint loads through the depth instead of crusting on the surface, so you extend service life. Many customers say they notice steadier airflow on day four than with older mats on day two. Not scientific, but I’ve heard it too many times to ignore.

Product snapshot (Paint Spray Booth Filter Media)

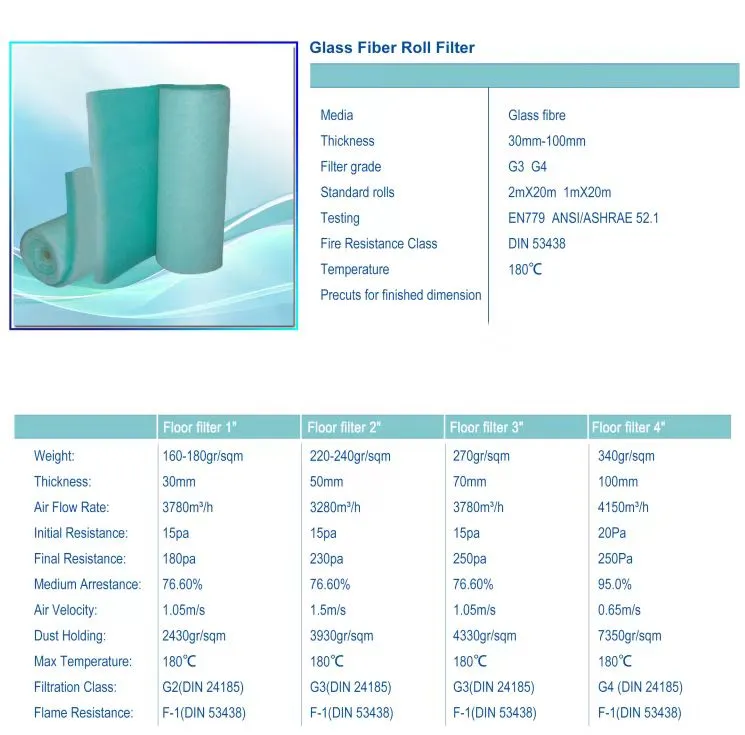

| Media | Glass fiber, progressive density (green/white) |

|---|---|

| Thickness | 30–100 mm (≈) |

| Filter grade | G3–G4 per EN 779 (legacy) |

| Roll sizes | 2 m × 20 m; 1 m × 20 m (standard) |

| Temperature | Up to 180°C |

| Fire resistance | DIN 53438 compliant (class per spec; ask cert) |

| Typical arrestance | ≈ 98% for coarse overspray; real‑world use may vary |

| Holding capacity | ≈ 3–5 kg/m² (application dependent) |

Origin: Second Buliding and Studying No21 shiji street, Handan, Hebei China.

How it’s made (quick process flow)

- Materials: continuous glass fibers, phenolic/thermoset binder, color indicator veil.

- Methods: fiber opening → web formation → progressive layering → binder spray → thermal curing → calendaring → slitting/rolling.

- Testing: thickness/area weight; initial ΔP at 0.5–1.0 m/s; arrestance per EN 779/ASHRAE 52.1 (legacy); fire per DIN 53438; optional ISO 9001 QA.

- Service life: change at ΔP setpoint or when overspray breakthrough appears—most shops report 20–60 booth hours, heavily variable by paint load.

- Industries: automotive refinish, furniture, metal fab, rail, marine, aerospace touch‑up.

Where it shines

In exhaust decks, paint stop filter media catches wet overspray before it hits fans and stacks. In intake walls, G3/G4 prefiltration keeps costlier final filters from loading too fast. I guess the main surprise is how much energy you save by swapping before the “cliff” in pressure rise.

Vendor snapshot (what buyers compare)

| Vendor | Lead time | Custom widths | Certs | Price band |

|---|---|---|---|---|

| FiltersMaterial (Hebei, CN) | ≈ 7–15 days | 0.5–2.1 m; pads on request | DIN 53438; ISO 9001 (on request) | $ |

| Premium EU brand | ≈ 2–4 weeks | Broad, fast-change SKUs | ISO 16890 data; DIN 53438 | $$$ |

| Trading-house B | Stock-dependent | Limited | Basic CoC | $$ |

Note: comparative info is indicative; real-world availability and certifications should be verified during sourcing.

Customization & testing

- Widths: 0.5–2.0 m; pads die-cut for floor grates.

- Basis weights and thickness tuned to booth velocity (try 50–75 mm at 0.6–0.8 m/s).

- Fire: DIN 53438 certificate; ask for lot-based test sheets.

- Data: initial ΔP ≈ 30–70 Pa; breakthrough tests against solvent and waterborne paints.

Two quick case notes

Automotive refinish shop, Midwest — Switched to 50 mm paint stop filter media; filter change interval moved from 2.5 to 4.5 days; fan cleaning frequency dropped 30%. Operators said odor spikes were lower after day three, which tracks with better depth loading.

Furniture plant, EU — 75 mm mat at 0.7 m/s; recorded 22% less downtime over a quarter. Energy audit showed ~5% savings because swaps were scheduled at a tighter ΔP window.

Final buying tips

- Match thickness to overspray load; don’t over-spec for light work.

- Ask for DIN 53438 and recent arrestance/ΔP curves; real booths aren’t labs, but trends matter.

- Plan changeouts by pressure, not the calendar.

- Keep spares dry—glass fiber can pick up moisture and skew ΔP.

Customer feedback, paraphrased: “Fewer clogs, cleaner fans.” “Actual savings showed up in labor, not just filter cost.” It seems that the simplest spec—good old paint stop filter media—still carries the booth on most days.

References

- EN 779:2012 – Particulate air filters for general ventilation (legacy classification G1–F9).

- ISO 16890:2016 – Air filters for general ventilation (ePM ratings; context for intake stages).

- DIN 53438 – Testing of materials; behavior under the influence of flame (filter media fire classes).

- ASHRAE 52.1/52.2 – Methods for testing air-cleaning devices; arrestance and pressure drop fundamentals.

- NFPA 33 & OSHA 1910.107 – Spray application using flammable/combustible materials; booth safety.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog