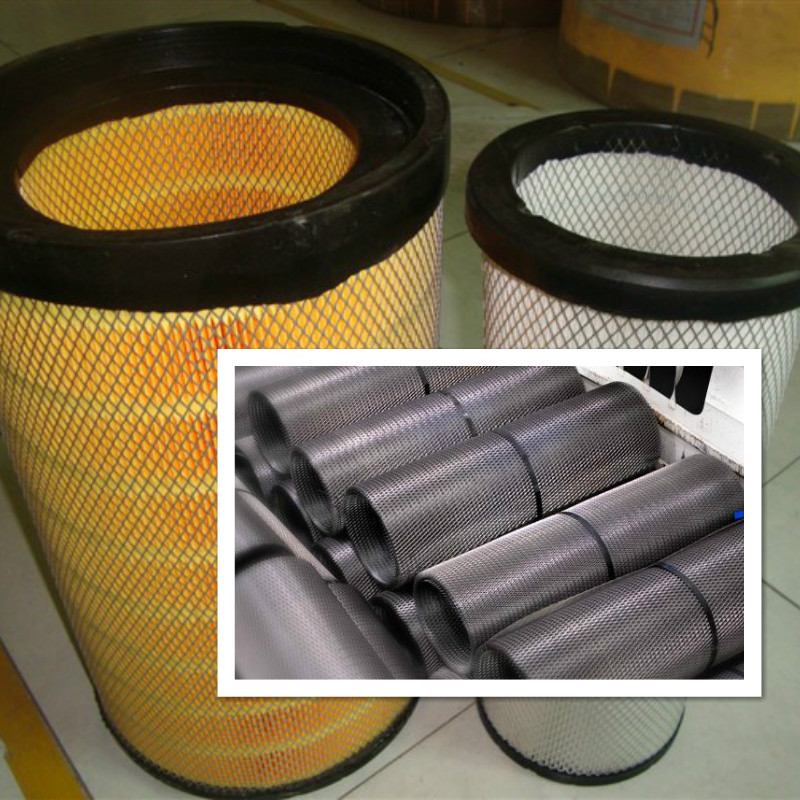

Expanded performance: Expanded Metal Mesh for Air Filters

If you work around HVAC frames, paint booths, or turbine intakes, you know the quiet hero is the support layer. And, to be honest, the market has leaned hard back to metal. Recyclable, stiff, predictable. That’s why Expanded Metal Mesh for Air Filters keeps popping up in spec sheets and, increasingly, in purchase orders.

What’s trending (and why it matters)

- ISO 16890 adoption is pushing consistent, low-resistance support media.

- Fire safety and reusability: metal backers beat plastics in hot, dusty plants.

- Predictable pleat stability = longer service intervals and fewer blowouts.

Core specs at a glance

| Parameter | Spec (typical) | Notes |

|---|---|---|

| Thickness | 0.2–6 mm (custom) | Raised or flattened |

| Strand thickness | 0.5–8 mm | Load-bearing tuning |

| SWD / LWD | SWD 2.5–100 mm; LWD 4.5–200 mm | ≈30–75% open area, real-world use may vary |

| Materials | Low-carbon steel, Al 3003/5052, SS 304/316 | Pick for weight, corrosion, or cost |

| Surface | Powder coated; Galvanized | Salt spray rated options |

Process flow (quick but complete)

Material selection → Slit-and-stretch expansion → Leveling/flattening → Shear-to-size and edge forming → Surface treatment (powder or zinc) → QA. Testing includes mesh aperture checks (ASTM E2016), coating thickness (ASTM D7091), adhesion (ASTM D3359), and corrosion exposure (ASTM B117). For filter assemblies, airflow resistance is validated to ISO 16890 or ASHRAE 52.2. Typical mesh-only ∆P at 1.5 m/s: ≈5–15 Pa, depending on open area and finish.

Where it’s used

- HVAC prefilters and pleated backers (commercial buildings, hospitals).

- Paint booths and powder lines (it resists sag and heat, surprisingly well).

- Gas turbine/engine intakes and compressor rooms.

- Automotive cabin and off-road equipment filters.

Advantages we actually see in the field

- Rigid pleat support = less media cracking, longer life (often +10–25%).

- Fire-safe, solvent-tolerant, and recyclable.

- Custom SWD/LWD balances pressure drop vs. stiffness; it’s a useful dial.

Vendor snapshot (what buyers compare)

| Vendor | Materials | Min SWD | Finish | Lead Time | Certs | Notes |

|---|---|---|---|---|---|---|

| FiltersMaterial (Handan, Hebei) | Steel, Al, SS | ≈2.5 mm | Powder, Galv | 10–18 days | ISO 9001, RoHS/REACH | Tight tolerances, OEM packs |

| Regional Fabricator | Steel | ≈5 mm | Galv only | 2–4 weeks | Varies | Good for small runs |

| Import Broker | Steel, Al | ≈3–6 mm | Powder | 4–8 weeks | Unknown | Price-driven, check QC |

Customization, cases, and real outcomes

Expanded Metal Mesh for Air Filters can be tuned for SWD/LWD to match pleat pitch, with coatings set to 60–80 μm for damp zones. Many customers say the upgrade pays back quickly.

- Paint line case: galvanized, flattened mesh cut filter collapse incidents by 70% and extended change-out by ≈22% (shop log data, 6 months).

- Hospital AHU: aluminum mesh backer reduced filter ∆P drift and simplified disposal (lighter frame), according to facilities feedback.

Service life and compliance

In clean commercial duty, coated steel backers run 3–7 years; stainless or aluminum in coastal/chem environments can push longer. Compliance/certs: ISO 9001 manufacturing, RoHS/REACH materials, corrosion testing to ASTM B117, geometry to ASTM E2016. Assemblies validated per ISO 16890 or ASHRAE 52.2 by the filter maker, of course.

Origin: Second Buliding and Studying No21 shiji street, Handan, Hebei China

References

- ISO 16890: Air filters for general ventilation.

- ASHRAE 52.2: Method of Testing General Ventilation Air-Cleaning Devices.

- ASTM E2016: Standard Specification for Industrial Woven Wire Cloth and Expanded Metal.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ASTM D3359/D7091: Coating adhesion and dry film thickness measurement.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog