What I’ve Learned About spray booth ceiling filters after a decade on the finishing floor

If you work around paint all day, you start to notice the little things—like how a great ceiling intake media can make a booth feel calmer, brighter, less dusty. Sounds soft, but it’s not. It’s throughput. It’s rework avoided. And, to be honest, it’s your reputation when a tri-coat white leaves flawless.

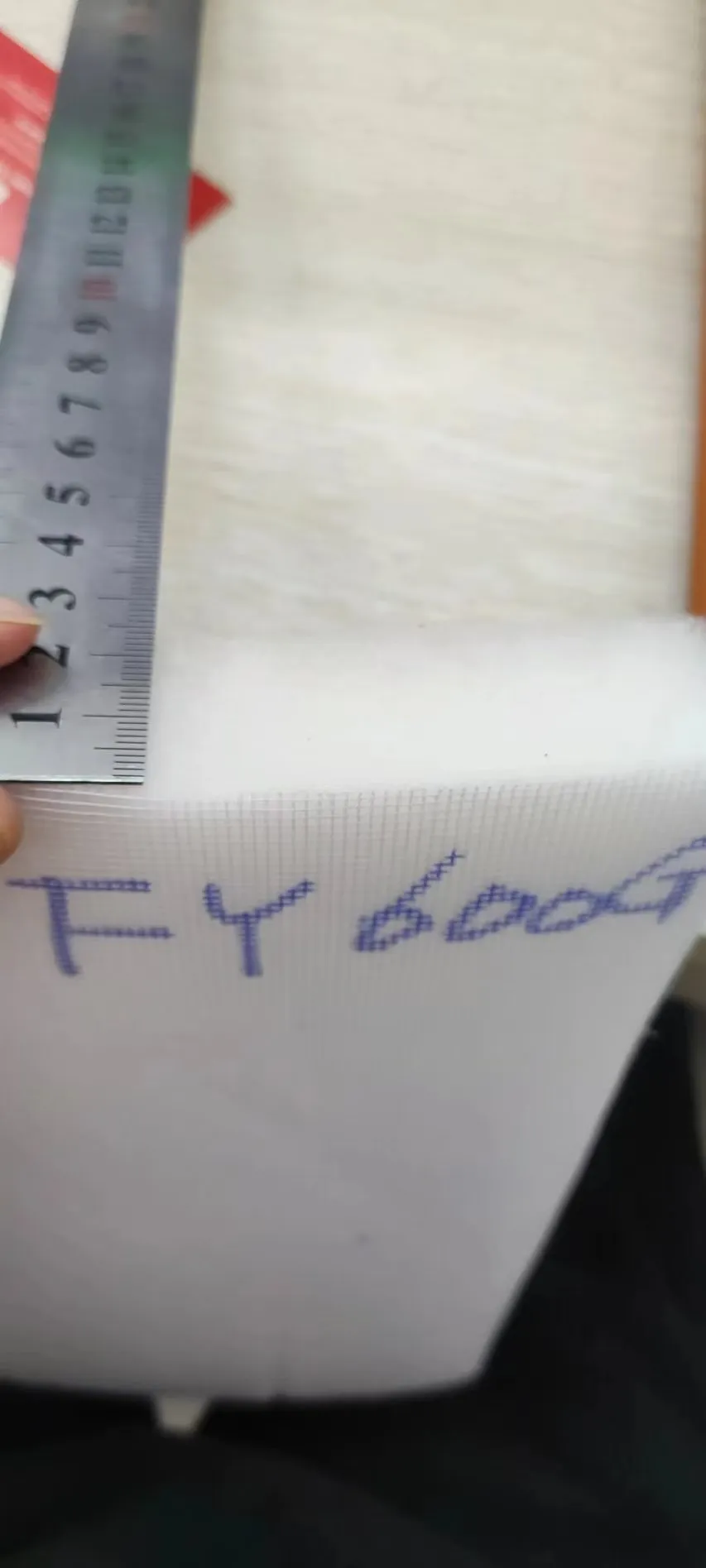

Product snapshot and real-world specs

The Spray Booth Ceiling Filter I’ve tested recently from Handan, Hebei (yep, the factory on Shiji Street) runs a progressive-density polyester, tackified, with a scrim backer. It’s a familiar recipe that just works.

| Material | 100% polyester fibers, progressive density, tackified face, scrim backing |

| Filtration Class | F5/M5 (EN 779:2012); roughly aligns to ISO 16890 ePM10 class (≈50% range, real-world may vary) |

| Weight | 550–600 g/m² |

| Max Temperature | 120°C |

| Typical Thickness | ≈18–22 mm |

| Initial Pressure Drop | ≈40–70 Pa @ 0.3–0.5 m/s face velocity |

| Dust Holding Capacity | ≈450–650 g/m² (lab conditions) |

| Service Life | 8–16 weeks typical in refinish; up to 6 months in light-duty intake use |

Trends shaping intake media (and why you should care)

Two things are happening. First, shops are switching to waterborne and low-VOC coatings, which don’t forgive dust. Second, regulators and insurers push better airflow uniformity (see NFPA 33) and newer test language (ISO 16890 largely replaced EN 779). Many customers say the move to higher loft ceiling media with consistent diffusion made the biggest quality jump this decade. I’d agree.

Where spray booth ceiling filters earn their keep

- Automotive refinish booths (downdraft/semidowndraft) – fewer nibs, smoother metallic lay.

- Industrial finishing cells – powder topcoat rooms, plastic parts, rail/coach interiors.

- Wood finishing – clear coats, where one speck can ruin an entire face frame.

Maintenance tip: log static pressure weekly; change when ΔP rises ≈2–3× initial, or booth anemometer drops below spec velocity.

How they’re made (quick process flow)

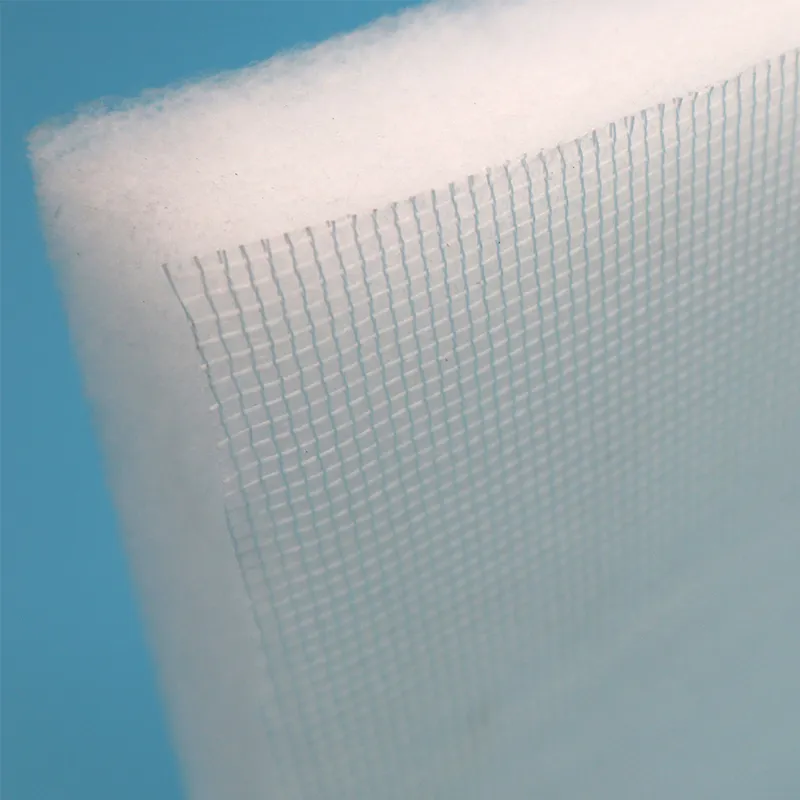

- Fiber selection: thermally bonded polyester grades blended for progressive density.

- Web forming: needled/lofted to target thickness and porosity; tackifier applied to clean-air side.

- Reinforcement: scrim backing laminated for mounting strength and anti-sag.

- Cutting/converting: rolls/sheets trimmed to booth grids; edges heat-sealed where requested.

- Testing: arrestance per EN 779 legacy and ISO 16890 mapping, pressure drop curve, airflow uniformity check, and basic flame spread screening (per local code).

Vendor landscape (what I look for)

| Vendor | Strengths | Lead Time | Certs/Docs |

|---|---|---|---|

| Factory (Handan, Hebei) | Direct cost, custom sizes, F5/M5 media control | ≈10–20 days | COC, test report mapping to ISO 16890 |

| Regional Distributor | Stock on hand, fast replacement, local support | 1–3 days | MSDS, basic performance sheet |

| Import Aggregator | Bulk pricing, mixed SKUs | ≈3–6 weeks | Varies; verify before buy |

Customization and field notes

Options I’ve seen work: pre-cut tiles for grid ceilings; extra-tacky face for dusty facilities; edge gasketing to stop bypass; color-coded clean-air side (sounds trivial, saves mistakes). Install with arrows facing airflow—surprisingly, that’s still missed.

Mini case notes

- Body shop, Midwest USA: switch to spray booth ceiling filters with tighter loft cut nib complaints by ≈40% in two months; painter said “metallics lay more even, less mottling.”

- Furniture plant: after sealing leaks and upgrading to EU5 media, booth velocity uniformity improved from 0.23–0.43 to 0.31–0.36 m/s, transfer efficiency ticked up a few points.

Origin: Second Building and Studying, No. 21 Shiji Street, Handan, Hebei, China. Always verify local code requirements (NFPA 33, OSHA) and map EN 779 classes to ISO 16890 when submitting to quality or EHS.

References

- ISO 16890: Air filters for general ventilation – performance testing and classification.

- EN 779:2012 (legacy): Particulate air filters for general ventilation – determination of filtration performance.

- NFPA 33: Standard for Spray Application Using Flammable or Combustible Materials.

- OSHA 29 CFR 1910.107: Spray finishing using flammable and combustible materials.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog