The Ceiling Matters: What I’m Seeing in Spray Booth Filtration Right Now

If you’re speccing spray booth ceiling filters this season, here’s the frank take from the floor: airflow uniformity is everything, and cheap media will quietly tax your finish quality—and your rework rate.

Why ceiling media sets the tone

Ceiling intake media does two jobs: it evens out velocity (so you don’t get striping, mottling, or dry spray) and it keeps dust from the airstream off wet surfaces. Many customers say once they switch to a well-tackified EU5/F5 media, defects fall noticeably—sometimes by half. To be honest, that aligns with what I’ve seen in body shops and furniture lines from Ohio to Shenzhen.

Product snapshot (what matters on the spec sheet)

| Parameter | Value (typical) |

|---|---|

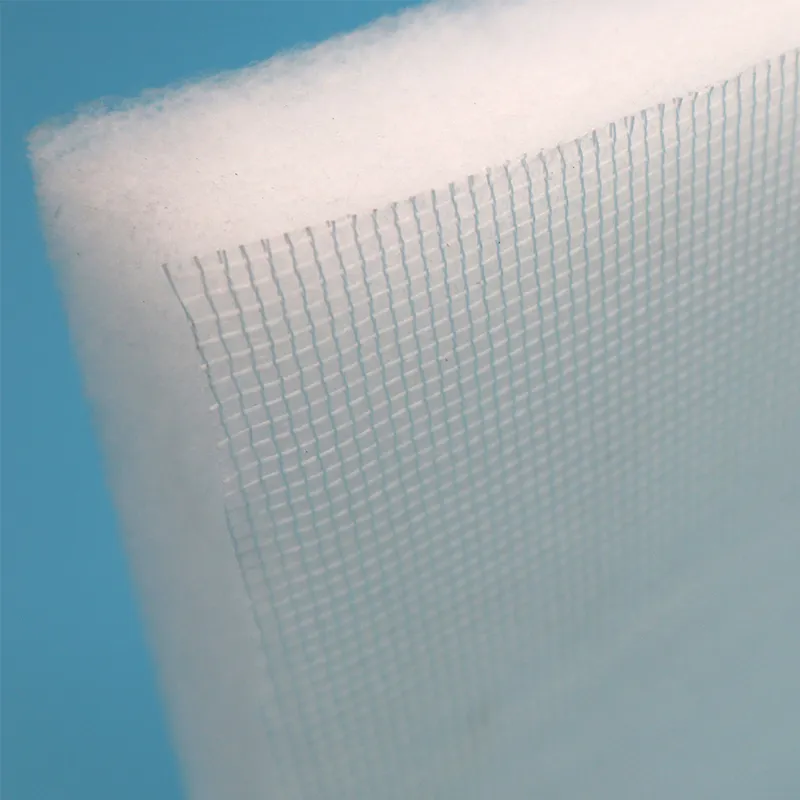

| Media | 100% polyester fibers, progressive-density, tackified, scrim-backed |

| Filtration class | F5/M5 (EN 779), ≈ EU5; ISO 16890 rough equivalence: ePM10 (around 50–65%) |

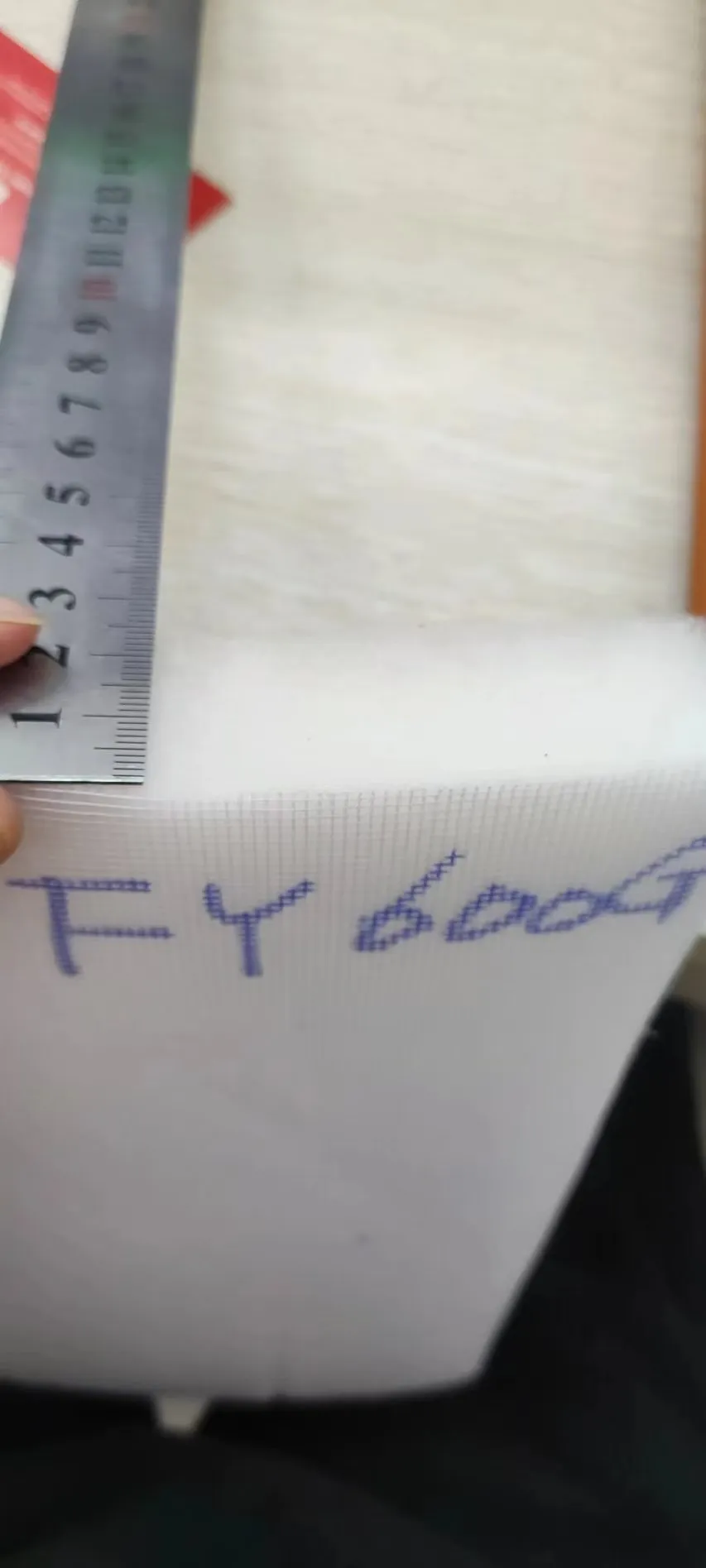

| Basis weight | 550 or 600 g/m² |

| Max temperature | 120°C |

| Thickness | ≈20 mm (real-world use may vary) |

| Initial resistance | ≈35–60 Pa @ 0.5 m/s |

| Dust holding | ≈400–600 g/m² |

Process flow, testing, and service life

- Materials: 100% polyester, thermal-bonded, progressive density; adhesive tackifier on clean-air side; scrim reinforcement.

- Methods: needled layers for diffusion; factory-tested rolls with lot traceability (ISO 9001 typical).

- Testing standards: EN 779 legacy classification; ISO 16890 mapping; optional DIN 53438 fire testing; pressure drop per ISO 16890 methodology.

- Service life: often 1–3 months (or 1,000–2,000 hours) depending on prep/sanding load and face velocity; change-out at ~200–250 Pa final resistance is common practice.

- Industries: automotive refinish, OEM paint, furniture and joinery, metal fab, small aerospace components.

Applications and customization

Downdraft and semi-downdraft booths benefit most; crossdrafts still gain from better diffusion. Rolls usually ship in 1.0–2.1 m widths, 20 m lengths; pre-cut pads and framed ceiling cassettes are available. Custom tack levels and scrim weights can be specified for high-sanding environments. Many shops, surprisingly, overlook sealing—don’t; even great spray booth ceiling filters can’t fix bypass leaks.

Vendor landscape (quick comparison)

| Feature | FiltersMaterial (Hebei) | Vendor A | Vendor B |

|---|---|---|---|

| Media class | F5/M5 (EU5) | M5–M6 | M5 |

| Max temp | 120°C | 100–120°C | 100°C |

| Custom widths | Yes (rolls/pads) | Limited | Yes |

| Certs | ISO 9001; test data on request | ISO 9001 | ISO 9001 |

| Lead time | Fast (factory-direct) | Moderate | Varies |

Origin: Second Buliding and Studying No21 Shiji Street, Handan, Hebei, China. In my notes, their support is pragmatic—cut sizes, labeling, and palletization are easy to dial in.

Trends and real-world outcomes

- Shift toward ISO 16890 labeling; EN 779 still referenced in older specs.

- Higher tack levels in prep-heavy shops; some add prefilters to extend ceiling media life.

- Data point: shops targeting 0.35–0.5 m/s face velocity report more consistent finishes and slower loading of spray booth ceiling filters.

Case 1: a collision center moved from generic M5 to tackified EU5 with scrim—reworks dropped ≈30% over 90 days. Case 2: a furniture plant added upstream panels and tightened gaskets; ceiling media change-outs went from monthly to every ~10 weeks.

Compliance notes

For paint ops, I typically check: NFPA 33 for spray application, OSHA 1910.107 for ventilation, and the filter classification via ISO 16890 (or legacy EN 779). Some buyers also ask for DIN 53438 fire class documentation and material safety confirmations (REACH/RoHS), which are usually available on request.

Bottom line: good spray booth ceiling filters are a quiet profit center. They don’t just trap dust—they stabilize your booth’s personality.

Authoritative references

- ISO 16890-1:2016, Air filters for general ventilation.

- EN 779:2012, Particulate air filters for general ventilation (legacy classification).

- NFPA 33, Standard for Spray Application Using Flammable or Combustible Materials (latest edition).

- OSHA 29 CFR 1910.107, Spray finishing using flammable and combustible materials.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog