Laminated Air Filter Media With Mesh: field notes, specs, and what buyers really ask

I’ve walked more AHU rooms than I can count, and one product that keeps popping up lately is laminated air filter media with metal mesh support. To be honest, it solves very practical problems—pleat stability, consistent pressure drop, and easy retrofits—without making a big fuss. The factory I’m referencing here ships from Second Buliding and Studying No21 shiji street, Handan, Hebei, China, and the vibe is pragmatic: make it strong, keep it clean, certify it properly.

What it is, in plain terms

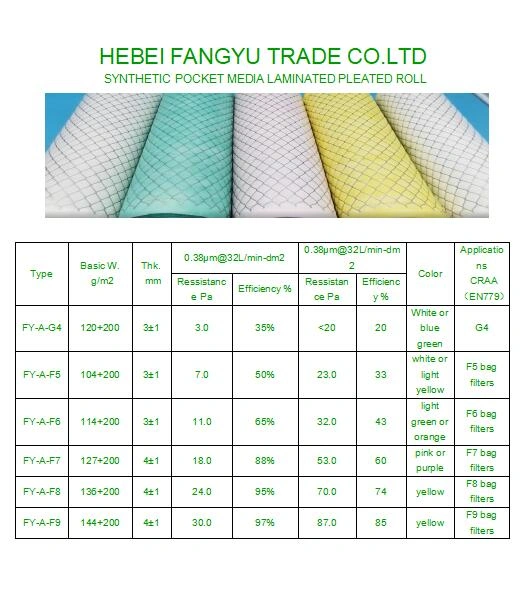

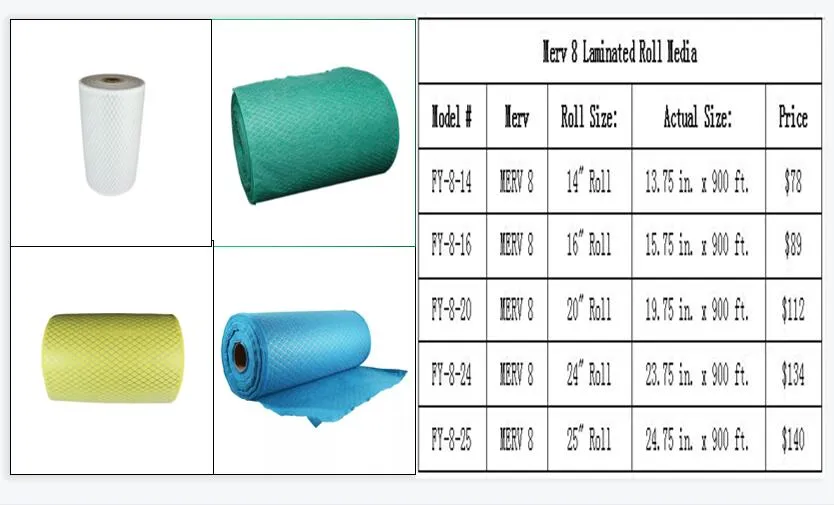

The core is 100% polyester fibre, laminated to a wire or expanded metal mesh. Grades span G3–F9 and MERV5–MERV14, which—actually—covers most pre/medium efficiency slots. Colors (white, blue, green, pink, yellow) are mainly identification cues. Maximum continuous service temperature around 80℃; that’s decent for HVAC, paint lines, and make-up air. Widths? Common rolls at 16”, 18”, 20”, 24”, 25” (custom cuts available). If you’re pleating, the mesh really helps the filter media keep its shape.

Process flow (condensed, but real)

- Materials: 100% polyester staple fibres, expanded/wire mesh, low-VOC adhesive system.

- Methods: carding → needle-punch/thermal bonding → calendaring → mesh lamination → slitting/roll-up.

- QC and testing: ASHRAE 52.2, ISO 16890, and legacy EN 779 classification; pressure drop at rated FPM; burst/peel tests; fiber shedding; color coding.

- Service life: ≈3–12 months in normal HVAC; faster in dusty paint or metal shops (real-world use may vary).

- Industries: commercial HVAC, food/bev prefilters, spray booths, compressor inlets, electronics assembly make-up air.

Product specifications (typical values)

| Grade | MERV | Basis weight (gsm) | Thickness (mm) | Initial ΔP @ 2.5 m/s (Pa) | Max temp |

|---|---|---|---|---|---|

| G4 | MERV8 | ≈180–220 | 7–10 | 45–60 | 80℃ |

| M6 | MERV11–12 | ≈220–260 | 8–12 | 70–90 | 80℃ |

| F7–F9 | MERV13–14 | ≈260–320 | 10–14 | 90–120 | 80℃ |

Note: values are typical; factory test data governs. Real-world HVAC conditions can shift ΔP and efficiency.

Industry trends I’m seeing

Post-ISO 16890, buyers ask for ePM10/ePM2.5/ePM1 data in addition to MERV. Pleatability matters—a lot—because installers want fewer frame changes. And—surprisingly—color coding helps facilities teams track upgrades. Many customers say the mesh-backed filter media resists damage during fast swaps, which is not a small thing on crowded catwalks.

Where it’s used (a quick list)

- Pre/secondary filters in rooftop units and AHUs.

- Spray booths capturing overspray; sanding bays.

- Commercial kitchens’ make-up air (upstream of final filters).

- Food, pharma, and electronics as a stable prefilter stage.

Vendor comparison (realistic snapshot)

| Vendor | Base fiber | Mesh support | Efficiency range | Temp limit | Notes |

|---|---|---|---|---|---|

| This product (Hebei, CN) | 100% polyester | Expanded/wire mesh | G3–F9 / MERV5–14 | 80℃ | Strong pleat stability; color options |

| Vendor B (EU) | Polyester blend | No mesh | G4–M6 | 70–80℃ | Lower cost; softer hand-feel |

| Vendor C (US) | Synthetic microfine | Metal grid | MERV11–14 | ≈82℃ | Premium QA; shorter lead times |

Testing, certifications, and data points

Tested to ASHRAE 52.2 (reporting MERV) and ISO 16890 (ePM classes). Typical F7 media shows ePM1 ≈ 50–65% and ePM2.5 ≈ 70–85% with initial ΔP of 90–110 Pa at 2.5 m/s. UL 900 flammability and ISO 9001 QA are available per lot records; RoHS/REACH compliance on request. If you want numbers by color code (some plants do), ask QC for the run sheet—simple and saves debate.

Customization and quick wins

- Widths cut to 16/18/20/24/25 inches; custom roll OD for your spindles.

- Color-coded filter media to match SOP levels (handy for audits).

- Mesh type (wire vs expanded), adhesive pattern, and basis weight tuned to your pleater.

Mini case notes

Paint line, Southeast Asia: switching to mesh-backed G4 prefilter cut media tears to near zero and extended changeout from 3 to 6 weeks; booth ΔP stabilized by ≈12%. Another: food plant AHU, MERV13 stage—operators liked that the filter media didn’t “collapse” when damp; coil fouling dropped noticeably within a quarter. Not lab-perfect, but convincing.

Bottom line? If you need a rugged, pleatable filter media that plays nicely with ISO 16890 and MERV reporting—and doesn’t scare your maintenance team—this one’s worth a trial roll.

Authoritative citations

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog