Introduction to Advanced Spray Booth Filtration

In precision finishing operations, particularly within the automotive, aerospace, and industrial coating sectors, the integrity of the paint application environment is paramount. A crucial component in maintaining pristine conditions and achieving flawless finishes is the sophisticated filtration system, specifically the spray booth ceiling filters. These filters are engineered to deliver a uniform, contaminant-free airflow, which is essential for preventing defects such as fisheyes, craters, and other particulate inclusions that compromise surface quality.

This comprehensive guide delves into the technical intricacies, application benefits, and strategic considerations for selecting and implementing high-performance spray booth ceiling filters. We will explore their manufacturing process, key technical specifications, diverse application scenarios, and the tangible advantages they offer in demanding industrial settings. Furthermore, we will address vendor comparison, customized solutions, real-world case studies, and essential trustworthiness components crucial for B2B decision-makers and technical engineers.

Industry Trends and Market Demands for Filtration Excellence

The industrial coating landscape is continually evolving, driven by stringent regulatory requirements, escalating demands for product quality, and the imperative for operational efficiency. Key trends influencing the market for spray booth ceiling filters include:

- Environmental Regulations: Increasing global emphasis on reducing VOC (Volatile Organic Compound) emissions and particulate matter necessitates highly efficient filtration systems that capture a broader spectrum of airborne contaminants. This drives innovation in filter media design and tackifier technology.

- Advanced Coating Technologies: The shift towards more sophisticated, multi-layer, and specialized coatings (e.g., ceramic, UV-curable, low-VOC paints) demands even higher levels of air purity to ensure optimal adhesion, gloss, and durability.

- Automation and Robotics: As paint booths become increasingly automated, the consistency of the painting environment, including airflow and filtration, must be meticulously controlled to maximize robot efficiency and minimize manual rework.

- Energy Efficiency: There’s a growing demand for filters that offer lower initial pressure drop and longer service life, directly contributing to reduced fan energy consumption and fewer filter change-outs, thereby lowering operational costs.

- Smart Filtration Systems: Emerging technologies include filters with embedded sensors for real-time monitoring of pressure drop and remaining service life, enabling predictive maintenance and optimized filter replacement schedules.

These trends underscore the critical role of advanced filtration in maintaining competitive edge and compliance within the industrial finishing sector. Manufacturers are continuously innovating to meet these stringent requirements, focusing on material science, aerodynamic design, and sustainability.

The Advanced Manufacturing Process of Spray Booth Ceiling Filters

The production of high-performance spray booth ceiling filters is a meticulously controlled process designed to achieve optimal air distribution and particle retention. Unlike metal components, filter manufacturing focuses on fiber engineering and media preparation. The typical process flow involves:

- Material Selection: High-grade synthetic fibers, primarily polyester and sometimes polypropylene, are chosen for their consistent diameter, tensile strength, and resistance to chemical degradation. These materials ensure durability and effectiveness in diverse paint environments.

-

Fiber Processing & Progressive Density Layering:

- Fibers are blended and carded to form a uniform web.

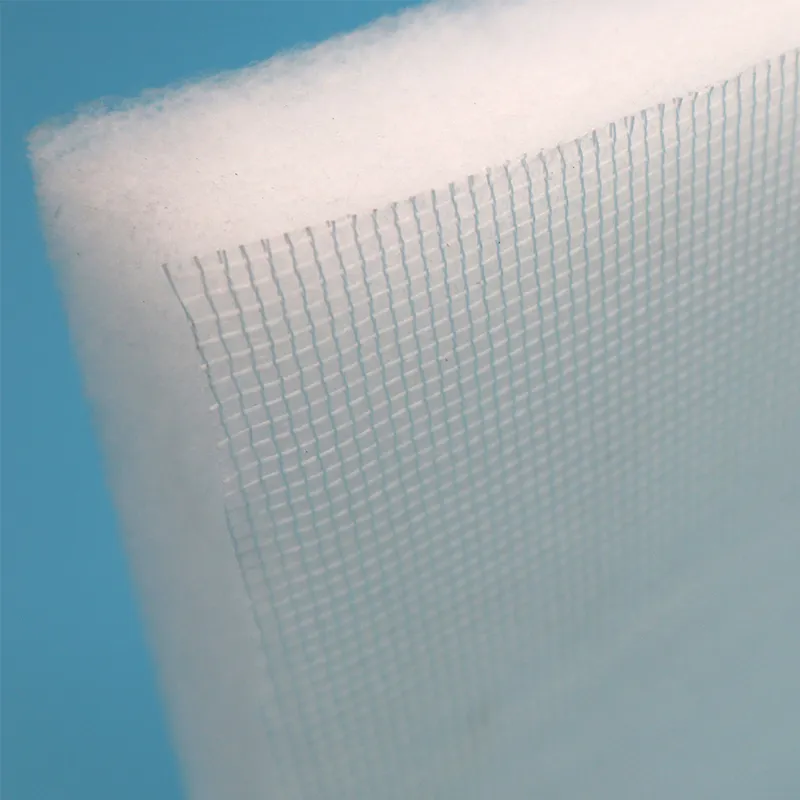

- Multiple layers are then progressively structured, with coarser fibers on the air-entering side and finer fibers on the air-leaving side. This progressive density design optimizes dust holding capacity and extends service life by capturing larger particles first, preventing premature clogging of the finer layers.

- Thermal bonding or needle punching techniques are employed to mechanically intertwine the fibers, ensuring structural integrity and preventing fiber migration, even under high airflow conditions.

- Tackifier Application: A specialized, non-migrating tackifier adhesive is uniformly applied to the fibers, particularly on the downstream side. This sticky resin enhances particle capture efficiency, preventing fine dust particles from dislodging and entering the paint booth.

- Scrim Backing (Optional but Recommended): A robust synthetic scrim backing is often heat-sealed or bonded to the clean air side of the filter media. This scrim provides additional structural stability, prevents fiber shedding, and ensures consistent laminar airflow, critical for a flawless finish.

- Cutting and Framing: The filter media is precisely cut into standard or custom sizes. For panel filters, it is then sealed into a robust, moisture-resistant cardboard or metal frame, often with a support grid, to maintain its shape and ensure a tight seal within the filter housing.

-

Quality Control & Testing: Each batch undergoes rigorous testing against international standards such as EN 779:2012 (replaced by ISO 16890) and ASHRAE 52.2. Key parameters tested include:

- Initial and final pressure drop (resistance to airflow)

- Arrestance efficiency (total particle capture)

- Dust holding capacity (amount of dust a filter can hold before reaching its final pressure drop)

- Airflow resistance at various velocities

- Fiber integrity and tackifier adhesion

These meticulous steps ensure that each filter meets the highest performance standards, delivering consistent, clean airflow for critical painting applications. The typical service life of these filters can range from 300 to 1000 hours of operation, depending on the paint load, environmental conditions, and specific product design.

Target industries benefiting from these highly engineered filters include:

- Automotive manufacturing and refinishing (OEM and aftermarket)

- Aerospace and aviation coatings

- Furniture and wood finishing

- Heavy machinery and equipment painting

- Plastics and composites coating

In these scenarios, the advantages are palpable: energy saving through optimized airflow, superior corrosion resistance (by preventing corrosive particle deposition), and a consistently high-quality finish reducing rework.

Technical Specifications and Performance Metrics

Understanding the technical specifications of spray booth ceiling filters is critical for optimal selection and performance. These parameters quantify the filter’s efficiency, airflow resistance, and operational lifespan.

Key Performance Parameters:

- MERV Rating (Minimum Efficiency Reporting Value, ASHRAE 52.2): Indicates the filter’s ability to capture airborne particles between 0.3 and 10 microns. For paint booths, MERV 13-16 (equivalent to F7-F9 in EN 779) is typically required for ceiling filters to capture fine overspray and dust.

- EN 779:2012 / ISO 16890 Classification: European standard for general ventilation filters. Ceiling filters typically fall into F5 (coarse filtration), F6, F7, or F8 (medium to fine filtration) categories, with F7 and F8 being common for high-quality finishing. ISO 16890 (ePM1, ePM2.5, ePM10) is the newer global standard, offering more detailed particle size efficiency.

- Initial Pressure Drop (Pa): The resistance to airflow exerted by a clean filter. A lower initial pressure drop translates to reduced energy consumption from fans.

- Final Pressure Drop (Pa): The maximum allowable pressure drop before the filter needs replacement. Exceeding this value significantly reduces airflow and compromises filter performance.

- Dust Holding Capacity (DHC, grams): The total amount of standard test dust a filter can accumulate before reaching its final pressure drop. Higher DHC means longer filter service life.

- Arrestance Efficiency (%): The percentage of total weight of coarse test dust removed from the air by the filter. Typically very high (95%+) for ceiling filters.

- Airflow Capacity (m³/h or CFM): The recommended volume of air that can pass through the filter efficiently.

- Temperature Resistance (°C/°F): The maximum continuous operating temperature the filter can withstand without degradation.

Typical Product Specification Table:

| Parameter | Unit | Typical Range (F5/EU5) | Typical Range (F7/EU7) |

|---|---|---|---|

| Filtration Class (EN 779:2012) | – | F5 / EU5 | F7 / EU7 |

| Filtration Class (ISO 16890) | – | ISO ePM10 50-65% | ISO ePM2.5 50-65% |

| Average Arrestance (Am) | % | >96% | >98% |

| Initial Pressure Drop (at 0.25 m/s) | Pa | 15 – 25 | 25 – 40 |

| Final Pressure Drop (Recommended) | Pa | 250 | 450 |

| Dust Holding Capacity (DHC) | g/m² | 200 – 350 | 300 – 500 |

| Max. Operating Temperature | °C / °F | 80°C / 176°F | 80°C / 176°F |

| Material | – | Synthetic, progressively structured, tackified | Synthetic, progressively structured, highly tackified, scrim-backed |

These specifications allow engineers to precisely match the filter to the unique requirements of their paint booth, considering the type of paint, desired finish quality, and operating budget.

Critical Application Scenarios and Operational Benefits

The efficacy of paint booth ceiling filters is best demonstrated across a spectrum of industrial applications where precision coating is non-negotiable. These filters are instrumental in maintaining the integrity of the paint environment in various booth configurations.

Typical Application Environments:

- Automotive Refinishing Shops: Essential for delivering showroom-quality finishes on vehicles, preventing dust and debris from settling on freshly painted surfaces. Ensures compliance with OEM standards.

- Aerospace Manufacturing: Critical for coating aircraft components where even microscopic imperfections can compromise aerodynamic performance or structural integrity. High-efficiency filters maintain the ultra-clean conditions required for specialized aerospace coatings.

- Industrial Coating Lines: Used in manufacturing facilities for heavy machinery, agricultural equipment, and industrial components, where durable, high-quality finishes are required for protection against corrosion and wear.

- Furniture and Wood Finishing: Ensures a smooth, blemish-free surface on fine furniture and cabinetry, where aesthetic appeal is a primary selling point.

- Plastic and Composite Parts Finishing: Critical for achieving a high-gloss, defect-free finish on plastic fascias, electronic casings, and composite panels.

Operational Benefits in Specific Booth Types:

- Downdraft Booths: The ceiling filters facilitate a uniform, laminar airflow from the ceiling downwards, sweeping overspray and contaminants away from the painted object and into floor-level exhaust systems. This creates the cleanest possible painting zone.

- Semi-Downdraft Booths: While not as purely laminar as downdraft, effective ceiling filtration ensures that air entering the booth is clean, minimizing contamination even with partial horizontal airflow.

- Crossdraft Booths: Although less common for ceiling filtration, where present, they ensure the incoming air is scrubbed clean, preventing contamination from external sources.

The ability of these filters to create a controlled, clean painting environment translates directly into reduced defects, lower rework rates, significant material savings, and increased throughput. This enhances operational efficiency and product quality, contributing directly to profitability.

Technical Advantages Driving ROI

Investing in high-quality spray booth ceiling filters provides a multitude of technical advantages that translate into tangible returns on investment for industrial operations.

- Superior Air Purity and Defect Reduction: The primary advantage is the capture of fine dust, lint, and overspray particles, often down to sub-micron sizes. This drastically reduces paint defects such as “nibs,” fisheyes, and craters, leading to fewer reworks and superior finish quality. This directly impacts material and labor costs associated with re-sanding and re-painting.

- Uniform Laminar Airflow: Precision-engineered filter media, often supported by a scrim backing, ensures that air enters the booth in a smooth, non-turbulent, downward flow. This laminar flow prevents paint particles from recirculating and settling on wet surfaces, guaranteeing a consistent and even coating.

- Extended Filter Service Life: Filters with progressive density designs and high dust holding capacities last longer. This reduces the frequency of filter changes, minimizing downtime, labor costs, and disposal expenses.

- Optimized Energy Efficiency: Modern ceiling filters are designed with low initial pressure drop, meaning fans work less to move the required volume of air. This translates into measurable energy savings over the operational life of the filters, contributing to a lower carbon footprint and reduced utility bills.

- Enhanced Worker Safety and Environmental Compliance: By effectively capturing airborne contaminants, these filters contribute to a healthier work environment, reducing painter exposure to hazardous particulates. Furthermore, they support compliance with local and international air quality regulations, avoiding potential fines and demonstrating corporate responsibility.

- Chemical and Temperature Resistance: Constructed from synthetic media, these filters exhibit excellent resistance to common paint solvents and can withstand the typical temperature cycles of paint booth operations, including bake cycles (up to 80°C/176°F), without degradation.

These combined advantages underscore why selecting the right ceiling filter is not merely a maintenance task, but a strategic decision impacting product quality, operational costs, and overall business sustainability.

Vendor Comparison: Selecting the Optimal Filtration Partner

Choosing the right supplier for spray booth ceiling filters requires careful evaluation beyond just price. A comprehensive assessment includes product quality, technical support, customization capabilities, and long-term reliability.

Comparative Analysis of Filter Types:

| Feature/Filter Type | Standard (F5/EU5) | High-Efficiency (F7/EU7) | Premium Tackified (F8/EU8) |

|---|---|---|---|

| Filtration Class (EN 779) | F5 | F7 | F8 |

| Typical MERV Rating | MERV 10-12 | MERV 13-14 | MERV 15-16 |

| Media Material | Synthetic Polyester | Synthetic Polyester (finer fibers) | Synthetic Polyester/Polypropylene blend |

| Tackifier Presence | Lightly tackified | Moderately tackified | Heavily tackified, non-migrating |

| Scrim Backing | Often absent or light | Present, standard weave | Robust, densely woven |

| Initial Pressure Drop (at 0.25 m/s) | Low (15-25 Pa) | Medium (25-40 Pa) | Slightly higher (35-50 Pa) |

| Dust Holding Capacity | Good | Very Good | Excellent |

| Typical Application | General industrial, less critical finishes | Automotive refinishing, industrial OEM | Aerospace, high-end automotive, demanding finishes |

| Cost/Performance Ratio | High efficiency per dollar for basic needs | Balanced, good ROI for most applications | Premium investment for superior quality and defect reduction |

When comparing vendors, consider their adherence to international standards (ISO, EN), their reputation for product consistency, and their ability to provide technical support and tailored solutions. A trusted partner will offer not just a product, but a comprehensive filtration strategy.

Customized Solutions for Unique Industrial Demands

Industrial painting environments are rarely one-size-fits-all. Many operations require bespoke filtration solutions to accommodate specific booth dimensions, unique airflow requirements, or highly specialized coating processes. A capable supplier of spray booth ceiling filters will offer robust customization options.

Areas of Customization:

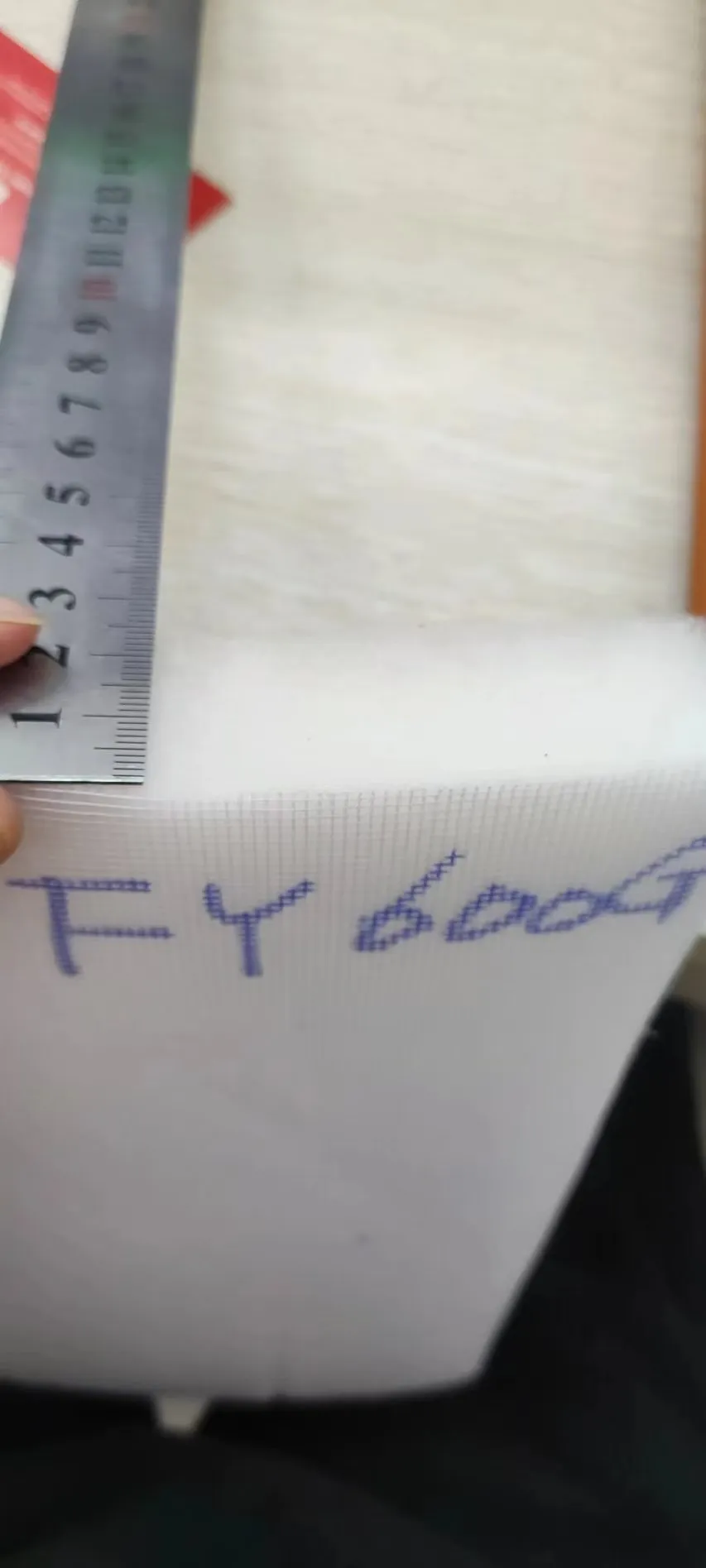

- Size and Dimensions: Filters can be manufactured to precise lengths, widths, and thicknesses to perfectly fit non-standard plenums and filter frames, ensuring an airtight seal and preventing bypass leakage.

- Media Selection: While synthetic polyester is standard, specialized media can be developed for enhanced chemical resistance (e.g., against aggressive solvents) or for specific particle size capture requirements beyond typical paint overspray.

- Tackifier Level and Type: The amount and type of tackifier can be adjusted. For example, a higher tackifier load for environments with extremely fine dust, or a specific formulation for compatibility with certain paint chemistries.

- Anti-Microbial or Anti-Static Treatments: In certain cleanroom-like painting applications, filters can be treated to inhibit microbial growth or to reduce static electricity buildup, which can attract dust.

- Frame Materials: While cardboard frames are common, metal frames can be specified for extreme durability or specific fire safety requirements.

- Certification Compliance: Custom solutions can be designed to meet specific local or industry-specific certifications that may exceed standard EN/ISO requirements.

Engaging with a vendor that possesses strong R&D capabilities and a flexible manufacturing process allows for optimized filtration performance that directly addresses operational challenges and cost efficiencies.

Application Case Studies: Real-World Impact

The tangible benefits of high-performance spray booth ceiling filters are best illustrated through real-world applications where they have significantly improved operational outcomes.

Case Study 1: Automotive OEM Plant Defect Reduction

- Challenge: A major automotive original equipment manufacturer (OEM) struggled with microscopic paint defects (nibs, dust particles) on vehicle body panels, leading to an average of 8% rework rate post-paint. The existing F6 ceiling filters were deemed insufficient for the plant’s high-gloss finishes.

- Solution: The plant upgraded its entire fleet of downdraft paint booths with premium F8 (MERV 15) spray booth ceiling filters featuring advanced tackifier and scrim backing. These filters were specified for uniform laminar flow and superior particle capture (ePM1 50-65% efficiency).

- Results: Within three months, the paint defect rate attributed to airborne particulates dropped by 65%, reducing the overall rework rate to below 3%. This resulted in an estimated annual saving of $1.2 million in labor, materials, and energy associated with rework, along with a significant increase in production throughput.

Case Study 2: Aerospace Component Coating Facility

- Challenge: An aerospace coating facility, specializing in anti-corrosion and stealth coatings for critical aircraft parts, faced challenges with short filter lifespans and occasional particulate contamination in their highly controlled environment. The requirement for zero defects was paramount.

- Solution: Custom-sized F7-equivalent ceiling filters with an extra-heavy, non-migrating tackifier and robust scrim backing were implemented. The filters were designed for extended dust holding capacity, optimized for a specific air change rate (ACR) and booth pressure.

- Results: Filter change-out intervals were extended by 40%, reducing maintenance labor and material costs. More critically, the incidence of particulate contamination-related rejections dropped to near zero, significantly enhancing product reliability and reducing costly scrap, demonstrating the value of precise filtration engineering in mission-critical applications.

These case studies underscore the quantifiable benefits that well-selected and properly maintained spray booth ceiling filters bring to industrial operations, extending beyond mere compliance to genuine operational excellence and financial gain.

Ensuring Trust and Reliability: Certifications, Support, and FAQ

For B2B partners, confidence in a supplier is built on transparency, robust support, and adherence to industry benchmarks. We emphasize full compliance and commitment to customer satisfaction.

Authoritative References & Certifications:

- ISO 9001: Our manufacturing processes adhere to internationally recognized quality management system standards, ensuring consistent product quality and continuous improvement.

- EN 779:2012 / ISO 16890 Compliance: All filters are tested and certified according to relevant European (EN) and International (ISO) standards for air filter performance, providing verifiable efficiency ratings.

- ASHRAE 52.2: Filters are also tested to ASHRAE standards, ensuring their MERV rating accurately reflects their performance in capturing particulate matter.

Lead Time & Fulfillment:

We maintain an agile supply chain and optimized production schedules to ensure competitive lead times for both standard and customized spray booth ceiling filters. Typical lead times for standard products range from 1-2 weeks, with expedited options available upon request. Custom orders are quoted with precise timelines based on complexity and volume, ensuring reliable delivery to minimize operational downtime for our clients.

Warranty & After-Sales Support:

Our spray booth ceiling filters come with a standard 12-month limited warranty against manufacturing defects, underscoring our confidence in product quality. Beyond the warranty, our dedicated technical support team is available to assist with product selection, installation guidance, troubleshooting, and performance optimization, ensuring long-term satisfaction and operational efficiency.

Frequently Asked Questions (FAQ):

Q1: How often should spray booth ceiling filters be replaced?

A1: Replacement frequency depends on factors such as paint volume, type of paint, booth utilization, and ambient air quality. Generally, filters should be replaced when the pressure drop across the filter reaches its recommended final pressure drop (e.g., 250-450 Pa) or when visible contamination appears on the downstream side, typically every 300-1000 operational hours.

Q2: What is the significance of the tackifier?

A2: The tackifier is a specialized adhesive applied to the filter media. It significantly increases particle capture efficiency by “sticking” fine dust and overspray particles, preventing them from being released downstream into the clean air stream and onto the painted surface. A high-quality, non-migrating tackifier is crucial for defect-free finishes.

Q3: Can these filters be washed or cleaned for reuse?

A3: No, spray booth ceiling filters are designed for single use. Attempting to wash or clean them will compromise their progressive density structure, tackifier properties, and overall filtration efficiency, potentially leading to immediate paint defects and reduced booth performance.

Q4: What’s the difference between EN 779 and ISO 16890?

A4: EN 779 was the older European standard, classifying filters into G (coarse) and F (fine) categories based on average arrestance and efficiency. ISO 16890 is the newer global standard, providing a more detailed classification based on a filter’s efficiency at capturing particulate matter sizes ePM1, ePM2.5, and ePM10, which aligns better with health and environmental impact assessments.

Conclusion

The selection and implementation of high-quality spray booth ceiling filters are foundational to achieving superior paint finishes, optimizing operational costs, and ensuring compliance in modern industrial coating processes. By understanding the intricate manufacturing processes, technical specifications, and real-world advantages, B2B decision-makers and engineers can make informed choices that directly impact product quality, efficiency, and environmental stewardship. Partnering with a reputable manufacturer that offers both standard and customized solutions, backed by robust support and stringent quality control, is key to unlocking the full potential of your paint booth operations.

References:

- ASHRAE Standard 52.2: Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size.

- ISO 16890: Air filters for general ventilation – Part 1: Technical specifications, requirements and classification system based on particulate matter efficiency (ePM).

- EN 779:2012: Particulate air filters for general ventilation – Determination of the filtration performance.

- “Paint Booth Design and Filtration Principles” – Journal of Industrial Coating & Finishing.

- Environmental Protection Agency (EPA) regulations concerning paint booth emissions and filtration.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog