Introduction to High-Performance Fiberglass Filter Media

In industrial air purification and HVAC systems, the selection of appropriate filtration technology is paramount for operational efficiency, regulatory compliance, and personnel health. Fiberglass filter media stands as a cornerstone material, renowned for its superior particulate capture capabilities, chemical resistance, and thermal stability. This advanced filtration solution is engineered to meet the stringent demands of modern industrial environments, providing exceptional performance across a broad spectrum of applications, from general ventilation to highly specialized cleanroom filtration. Understanding its technical intricacies, manufacturing processes, and diverse applications is crucial for B2B decision-makers seeking optimized air quality solutions.

Industry Trends & Market Dynamics

The global market for advanced filtration media, particularly fiberglass filter media, is experiencing robust growth, driven by escalating industrialization, stricter environmental regulations, and a heightened focus on indoor air quality (IAQ). Key trends include:

- Demand for Higher Efficiency: Industries are increasingly requiring filter media with MERV 13 (ePM1 50%) to MERV 16 (ePM1 80%) ratings or higher to capture finer particulate matter (PM2.5, PM1.0), allergens, and contaminants. This pushes innovation in finer glass fiber structures and multi-layered designs.

- Energy Efficiency: A significant trend is the development of fiberglass air filter media with lower pressure drop characteristics, which reduces the energy consumption of HVAC systems. This aligns with global sustainability initiatives and offers substantial operational cost savings.

- Customization and Specialized Applications: The market is moving towards highly customized solutions, where fiberglass filter media rolls are tailored for specific industrial processes, including high-temperature environments, corrosive atmospheres, or applications requiring specific chemical inertness.

- Integration with Smart Systems: Future developments include filter media integrated with sensors for real-time performance monitoring, predictive maintenance, and optimized replacement cycles, enhancing the overall efficiency of filtration systems.

- Sustainability and Lifecycle Management: While fiberglass itself is inert and durable, ongoing research aims at improving the recyclability of composite filter products and reducing the environmental footprint of their manufacturing processes.

These trends underscore the critical role of high-performance fiberglass filter material in addressing evolving industrial and environmental challenges.

Manufacturing Process & Quality Assurance

The Production Journey of Fiberglass Filter Media

The manufacturing of fiberglass filter media is a precise, multi-stage process designed to achieve specific filtration characteristics. The primary raw material is fine borosilicate glass fibers, chosen for their chemical inertness, high-temperature resistance, and excellent filtration capabilities.

- Glass Melting and Fiberization: High-purity glass raw materials are melted at elevated temperatures. The molten glass is then drawn into extremely fine fibers, often with diameters ranging from 0.5 to 10 micrometers, through a process like rotary fiberization or melt-blowing.

- Web Formation (Wet-laid or Dry-laid):

- Wet-laid Process: Fibers are dispersed in an aqueous solution, then uniformly laid onto a moving screen, similar to papermaking. This method ensures excellent fiber distribution and high uniformity, critical for consistent filtration efficiency.

- Dry-laid Process: Fibers are air-laid or carded to form a web. While simpler, achieving fine uniformity for high-efficiency media can be more challenging than with wet-laid methods.

- Binder Application and Curing: A specialized binder (e.g., acrylic or phenolic resin) is applied to the fiber web. This binder is crucial for imparting structural integrity, rigidity, and desired physical properties to the filter media. The web then passes through an oven where the binder is cured, cross-linking the fibers and creating a stable, durable matrix.

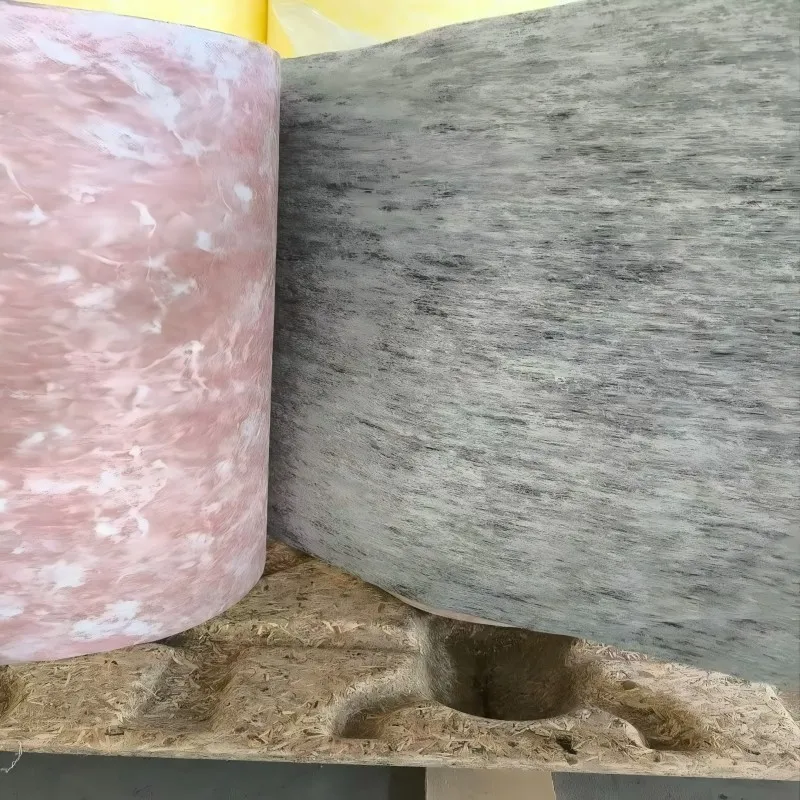

- Finishing and Slitting: After curing, the media may undergo calendering for thickness control or lamination with scrims for enhanced strength. The continuous roll is then precisely slit into narrower fiberglass filter media rolls according to customer specifications for further processing into finished filters.

- Quality Control and Testing: Throughout the process, rigorous testing is conducted. This includes measurements of basis weight, thickness, air permeability, tensile strength, and critically, filtration efficiency and pressure drop. Adherence to international standards such as ISO 16890, EN 779, and ASHRAE 52.2 is non-negotiable, ensuring the media meets defined performance criteria.

Target industries benefiting from this robust material include petrochemical, metallurgy, pharmaceuticals, food and beverage, and general HVAC. The advantages in typical application scenarios include significant energy saving due to optimized airflow and lower pressure drop, alongside superior corrosion resistance which extends the service life in harsh environments.

Technical Specifications & Performance Parameters

High-performance fiberglass filter media is characterized by a suite of technical parameters that define its suitability for specific filtration tasks. Key metrics include:

- Filtration Efficiency: Measured by MERV (Minimum Efficiency Reporting Value, ASHRAE 52.2) or ePM (ISO 16890), indicating the media’s ability to capture particles of various sizes (e.g., ePM1, ePM2.5, ePM10).

- Pressure Drop: The resistance to airflow across the filter media, measured in Pa or inches of water gauge (w.g.). Lower pressure drop translates to reduced energy consumption for fans.

- Dust Holding Capacity (DHC): The amount of dust a filter can hold before reaching its terminal pressure drop. A higher DHC extends filter life, reducing replacement frequency.

- Basis Weight: The weight per unit area (g/m² or oz/yd²), indicative of material density and often correlated with efficiency and pressure drop.

- Thickness: The caliper of the media, impacting its structural integrity and dust loading profile.

- Air Permeability: The volume of air that can pass through the media at a given pressure differential, measured in CFM/ft² or L/s/m².

- Thermal Stability: The ability to withstand high operating temperatures without degradation. Fiberglass typically performs well up to 250°C (480°F) or higher depending on the binder.

- Chemical Resistance: Inertness to a wide range of acids, bases, and organic solvents, making it ideal for corrosive environments.

Typical Specifications for Fiberglass Pocket Filter Media

| Parameter | Value Range (Typical) | Standard |

|---|---|---|

| Efficiency Rating | MERV 13 – MERV 16 (ePM1 50% to ePM1 80%) | ASHRAE 52.2 / ISO 16890 |

| Initial Pressure Drop (at 0.25 m/s) | 30 – 80 Pa | EN 779 / ISO 16890 |

| Dust Holding Capacity | 300 – 600 g/m² | ASHRAE 52.2 |

| Basis Weight | 100 – 250 g/m² | Internal / Industry |

| Thickness | 3 – 10 mm | Internal / Industry |

| Max. Operating Temperature | ~250°C (480°F) | Material Property |

Diverse Application Scenarios

The versatility and high performance of fiberglass filter material make it indispensable across a multitude of industrial and commercial sectors:

- HVAC Systems (Commercial & Industrial): Used extensively in air handling units for offices, data centers, hospitals, and manufacturing plants to protect coils, ductwork, and occupants from airborne contaminants. Fiberglass air filter media, particularly in pocket filter configurations, provides excellent efficiency for fine dust, pollen, and mold spores.

- Cleanrooms (Pharmaceutical, Semiconductor, Biotech): Critical for maintaining ultra-clean environments by serving as pre-filters or intermediate filters, extending the life of HEPA/ULPA filters and ensuring particle-free air crucial for sensitive processes.

- Paint Spray Booths: Efficiently captures overspray particles, protecting spray guns, improving finish quality, and preventing environmental contamination.

- Automotive Industry: Employed in manufacturing facilities for vehicle assembly, engine production, and painting processes to maintain air purity and protect sensitive machinery.

- Food & Beverage Processing: Used to filter air in processing areas, packaging lines, and cold storage to prevent contamination of products and maintain hygiene standards.

- Power Generation: Protects gas turbines and other sensitive equipment from airborne dust and pollutants, enhancing operational longevity and efficiency.

- Industrial Exhaust & Fume Control: Suitable for filtering various industrial exhaust streams, including those with elevated temperatures or chemical content, due to its thermal and chemical resistance.

Technical Advantages of Fiberglass Filter Media

The inherent properties of glass fibers, coupled with advanced manufacturing techniques, confer several distinct advantages to fiberglass filter media:

- High Filtration Efficiency: The fine, non-uniform structure of glass fibers creates a highly tortuous path, enabling efficient capture of both coarse and fine particulate matter through impaction, interception, and diffusion mechanisms. This translates to high MERV/ePM ratings.

- Excellent Dust Holding Capacity: The open, yet dense, structure allows for significant dust loading without rapidly increasing pressure drop, extending the operational life of filters and reducing maintenance costs.

- Low Initial Pressure Drop: Optimized fiber diameter and web formation result in media that offers minimal resistance to airflow while maintaining high efficiency, leading to substantial energy savings in fan operation.

- Superior Thermal Stability: Fiberglass is inherently resistant to high temperatures, making it suitable for applications where other synthetic media might degrade or melt. This is crucial in environments like industrial dryers or power generation plants.

- Exceptional Chemical Resistance: Glass fibers are largely unaffected by most acids, alkalis, and solvents, ensuring stable performance in chemically aggressive atmospheres where corrosion resistance is paramount.

- Hydrophobic Nature: Fiberglass does not readily absorb moisture, which prevents microbial growth and maintains structural integrity in humid conditions.

- Cost-Effectiveness: While offering premium performance, fiberglass filter material often provides an excellent balance of cost and longevity, leading to lower total cost of ownership compared to alternatives requiring more frequent replacement or higher energy consumption.

Vendor Comparison & Selection Criteria

When selecting a supplier for fiberglass filter media, B2B buyers must evaluate vendors beyond just price. A holistic approach focusing on several critical criteria ensures long-term value and performance:

- Product Quality & Consistency: Evaluate the consistency of the media’s technical parameters (efficiency, pressure drop, basis weight). Look for vendors with robust quality control processes and certifications (e.g., ISO 9001).

- Certifications & Compliance: Ensure the media meets international standards like ISO 16890, EN 779, or ASHRAE 52.2. Compliance with specific industry regulations (e.g., FDA for food contact applications) is also vital.

- Customization Capabilities: A capable vendor should offer flexibility in terms of media thickness, basis weight, efficiency levels, and roll dimensions to meet specific OEM or system requirements.

- Technical Support & Expertise: Access to experienced technical teams for application engineering, troubleshooting, and media selection advice can be invaluable.

- Supply Chain Reliability: Assess the vendor’s capacity, lead times, and ability to ensure a stable supply, especially for large-scale or just-in-time operations.

- Cost-Effectiveness (Total Cost of Ownership): Consider not just the purchase price, but also the longevity, energy savings, and maintenance reductions offered by the media.

Vendor Comparison Table Example (Illustrative)

| Feature | Vendor A (Premium) | Vendor B (Standard) | Vendor C (Budget) |

|---|---|---|---|

| Efficiency Range | MERV 13-16 / ePM1 50-80% | MERV 11-14 / ePM2.5 50-70% | MERV 8-10 / ePM10 50-60% |

| Customization Options | Extensive (width, thickness, basis weight, specialized binders) | Moderate (standard widths, few binder options) | Limited (fixed specifications) |

| Certifications | ISO 9001, ISO 16890, ASHRAE 52.2, EN 779 | ISO 9001, ASHRAE 52.2 | Basic internal quality control |

| Technical Support | Dedicated application engineers, R&D access | Standard customer service | Limited to product data sheets |

| Lead Time (Avg.) | 2-4 weeks | 3-5 weeks | 4-6 weeks |

Customized Solutions for Specialized Needs

Recognizing that standard filtration solutions may not suffice for all complex industrial challenges, leading manufacturers of fiberglass filter material offer extensive customization options. This approach allows for optimal integration into existing systems and addresses unique operational constraints:

- Tailored Dimensions: Fiberglass filter media rolls can be supplied in specific widths and lengths to precisely fit custom filter frames or automated filter manufacturing lines, minimizing waste and optimizing production.

- Varied Efficiency Levels: The ability to fine-tune the fiber density and structure allows for media to be engineered to achieve precise MERV or ePM ratings, balancing efficiency with pressure drop requirements for specific applications.

- Specialized Binders: Beyond standard acrylic binders, options include water-repellent, fire-retardant, or chemically resistant binders to enhance performance in harsh or regulated environments. For instance, activated carbon impregnated fiberglass can be developed for combined particulate and gaseous contaminant removal.

- Reinforcement & Lamination: The media can be reinforced with scrims (e.g., spunbond polyester) for added strength, tear resistance, and dimensional stability, crucial for demanding applications or certain filter pleating processes.

- Surface Treatments: Anti-microbial or oleophobic (oil-repellent) treatments can be applied to the media surface, extending filter life and preventing issues in specific industrial settings.

These customized solutions ensure that the fiberglass air filter media performs optimally, contributing to higher operational uptime and reduced maintenance overheads for industrial clients.

Application Case Studies & Customer Success

Case Study 1: Automotive Manufacturing Plant

A large automotive manufacturing facility faced persistent issues with paint finish quality and frequent filter changes in its high-volume spray booths. The existing synthetic media was prone to shedding and had limited dust holding capacity, leading to costly reworks and downtime.

- Challenge: Improve paint finish quality, reduce filter replacement frequency, and lower operational costs in spray booths.

- Solution: Implementation of a specialized, high-density fiberglass filter media designed for paint overspray capture. The media offered superior adhesion for paint particles and a higher dust holding capacity.

- Results: The plant reported a 30% reduction in paint finish defects, leading to significant savings in rework. Filter life was extended by 45%, reducing material costs and maintenance labor. The superior particulate capture of the fiberglass media also contributed to better indoor air quality for workers.

Case Study 2: Pharmaceutical Cleanroom Pre-filtration

A pharmaceutical company operating ISO Class 7 cleanrooms was experiencing premature loading of its expensive HEPA filters due to inefficient pre-filtration. This resulted in high HEPA filter replacement costs and increased operational expenditure.

- Challenge: Extend the lifespan of HEPA filters while maintaining stringent cleanroom particulate levels.

- Solution: Upgrading the pre-filtration stage to high-efficiency fiberglass air filter media (MERV 15 / ePM1 70%) in a multi-pocket configuration. This media was selected for its high initial efficiency and low pressure drop.

- Results: The new fiberglass pre-filters captured significantly more fine particles, extending the average lifespan of the downstream HEPA filters by over 60%. This translated to annual savings of approximately $50,000 in filter replacement costs and reduced associated downtime for maintenance.

Frequently Asked Questions (FAQ)

Q1: What makes fiberglass filter media superior to synthetic alternatives?

Fiberglass filter media typically offers higher thermal stability, superior chemical resistance, and often better dust holding capacity at comparable efficiencies due to the inherent properties and irregular, fine structure of glass fibers. Synthetic media can be a good choice for certain applications, but fiberglass excels in harsh or high-efficiency environments.

Q2: Is fiberglass filter media safe for use in food processing facilities?

Yes, when manufactured to appropriate standards and certifications, fiberglass filter material is widely used in food and beverage processing. It’s inert, doesn’t support microbial growth, and specialized binders can be selected to meet FDA compliance requirements for food contact or proximity applications.

Q3: How do I determine the correct MERV rating for my application?

The appropriate MERV or ePM rating for fiberglass air filter media depends on several factors: the required indoor air quality, the type and concentration of particulate matter, external air pollution levels, and downstream equipment protection needs. It is advisable to consult with filtration experts or refer to industry standards (e.g., ASHRAE 62.1) for specific guidance.

Q4: Can fiberglass filter media be recycled?

The recyclability of fiberglass filter media largely depends on its specific composition and the presence of binders or other composite materials. While the glass fibers themselves are recyclable, the bound filter media often poses challenges for conventional recycling streams. Efforts are ongoing in the industry to develop more easily recyclable filter products.

Lead Time, Warranty, and After-Sales Support

Lead Time & Fulfillment

Standard fiberglass filter media rolls typically have a lead time of 2-4 weeks, depending on order volume and current production schedules. Custom orders requiring specific specifications or specialized binders may require an additional 1-2 weeks for engineering and production setup. We maintain strategic stock levels of popular grades to facilitate expedited orders for urgent requirements. Our logistical network ensures efficient and reliable delivery worldwide.

Warranty Commitments

All fiberglass filter media products are backed by a comprehensive warranty covering manufacturing defects and material integrity for a period of 12 months from the date of purchase. This commitment underscores our confidence in the quality and reliability of our products, provided they are stored, handled, and used under recommended conditions. Specific warranty details are outlined in our product documentation.

Customer Support & Technical Assistance

Our dedication to customer success extends far beyond the sale. We provide extensive after-sales support, including:

- Technical Consultation: Our team of filtration experts is available to provide detailed technical advice, application engineering support, and performance optimization recommendations for fiberglass air filter media.

- Troubleshooting: Prompt assistance for any operational issues or performance concerns related to our filter media.

- Documentation & Resources: Access to comprehensive product data sheets, installation guides, and performance reports.

- Training: On-site or virtual training sessions can be arranged to educate client teams on filter media handling, application best practices, and performance monitoring.

Conclusion

Fiberglass filter media remains an unparalleled choice for industrial and commercial filtration, offering a robust combination of high efficiency, durability, and versatility. Its consistent performance across demanding applications, coupled with continuous innovation in its manufacturing and customization, solidifies its position as a critical component in ensuring clean air, protecting valuable equipment, and maintaining operational integrity. For B2B stakeholders prioritizing long-term performance and cost-effectiveness, investing in high-quality fiberglass filter material represents a strategic decision that yields significant returns.

References

- ASHRAE Standard 52.2: Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size.

- ISO 16890: Air filters for general ventilation – Part 1: Technical specifications, requirements and classification system based on particulate matter efficiency (ePM).

- EN 779: Particulate air filters for general ventilation – Determination of the filtration performance.

- Filtration and Separation Magazine. “Innovations in Glass Fiber Filtration Media.” Various Issues, Elsevier.

- United States Environmental Protection Agency (EPA). “Indoor Air Quality (IAQ) Standards.” www.epa.gov/iaq.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog