Introduction to Advanced Polypropylene Filter Media Solutions

In critical industrial filtration applications, the choice of media directly impacts operational efficiency, product purity, and environmental compliance. Among the myriad options, polypropylene filter media stands out for its exceptional chemical resistance, thermal stability, and mechanical strength. Its versatility makes it indispensable across a broad spectrum of industries, from petrochemical processing to municipal water treatment. This article delves into the technical intricacies, manufacturing excellence, diverse applications, and inherent advantages of modern polypropylene-based filtration solutions, providing B2B decision-makers and engineers with comprehensive insights into optimizing their filtration strategies.

Our Laminated Composite Filter Media represents the pinnacle of this technology, engineered to deliver superior performance and longevity in the most demanding environments. This advanced material integrates multi-layered structures to enhance filtration efficiency, dirt-holding capacity, and overall service life, addressing the evolving needs of industrial processes requiring high-purity fluid separation.

Manufacturing Process of Laminated Composite Filter Media

The production of high-performance polypropylene filter media, particularly our Laminated Composite Filter Media, involves a meticulous, multi-stage process designed to ensure structural integrity, consistent pore size distribution, and optimal filtration characteristics. This complex manufacturing journey integrates advanced material science with precision engineering.

Materials and Preparation:

The foundational material is high-grade polypropylene resin, selected for its inertness, hydrophobic properties, and excellent chemical resistance. Depending on the application, additional polymers or functional additives may be incorporated to enhance specific properties like heat resistance or oleophobicity. Rigorous incoming material inspection ensures compliance with international standards such as ASTM D4101 for polypropylene plastics.

Process Flow:

1. Extrusion of Polypropylene Fibers/Sheets

High-purity PP resin is melted and extruded into fine fibers or thin films through a spinneret or die. This step controls fiber diameter and structure.

2. Non-Woven Web Formation

Fibers are collected and laid randomly (spunbond, melt-blown) to form a non-woven web, establishing initial porosity and basis weight.

3. Lamination and Bonding

Multiple layers of non-woven PP, often with varying pore sizes, are thermally or ultrasonically bonded. This creates the composite structure.

4. Functional Treatment & Finishing

Post-treatment like calendering for density control, surface treatments for enhanced hydrophilicity/hydrophobicity, and slitting to final dimensions.

Quality Control and Testing Standards:

Throughout the process, stringent quality control measures are implemented. Key parameters such as tensile strength (ASTM D5035), burst strength (ASTM D3786), air permeability (ASTM D737), basis weight (ASTM D3776), and micron rating (ISO 16889) are continuously monitored. Our products adhere to international standards like ISO 9001 for quality management and, where applicable, FDA compliance for food and beverage contact materials, ensuring reliability and safety.

Service Life and Target Industries:

The service life of our polypropylene filter media is engineered for extended periods, typically ranging from 6 to 24 months depending on the application severity, flow rate, and contaminant load. This extended lifespan translates to reduced maintenance costs and fewer change-outs. Target industries benefiting from these materials include petrochemical, metallurgy, municipal and industrial water supply & drainage, pharmaceuticals, food & beverage, and electronics manufacturing. In demanding environments like chemical processing, our media provides exceptional corrosion resistance against acids, bases, and many organic solvents, significantly outperforming conventional materials.

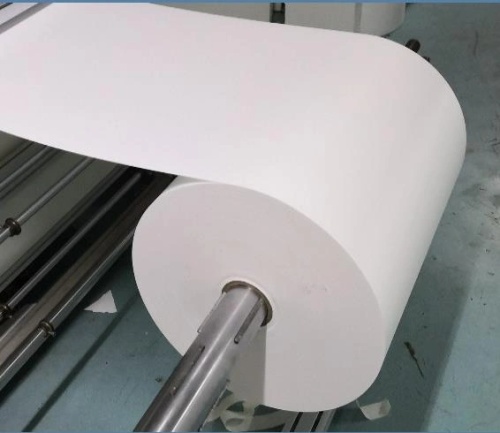

Figure 1: Illustration of a multi-layered polypropylene filter media structure.

Industry Trends and Market Dynamics

The global industrial filtration market is experiencing robust growth, driven by increasing regulatory pressures, rising demand for clean water, and the need for higher product quality in various manufacturing sectors. Within this landscape, polypropylene filter media continues to be a dominant force due to its cost-effectiveness, broad chemical compatibility, and versatility.

- Sustainability Focus: There’s a growing emphasis on environmentally friendly and sustainable filtration solutions. Manufacturers are exploring ways to improve the recyclability of filter media and extend its lifespan to reduce waste. Innovation in manufacturing processes to lower energy consumption is also a key trend.

- Advanced Composites: The development of laminated and composite structures, like our flagship product, is a significant trend. These materials combine the benefits of different layers, optimizing filtration efficiency, dirt-holding capacity, and structural integrity. This allows for finer filtration (e.g., sub-micron particulate removal) with lower pressure drops.

- Emergence of Specialized Media: While polypropylene filter media remains a staple, specialized media such as pet filter media are gaining traction in specific sectors, particularly those dealing with pet care products or animal waste management, where odor control and fine particulate removal are paramount. Similarly, the demand for highly efficient activated filter media is surging in applications requiring adsorption of dissolved contaminants, odors, and colors, complementing mechanical filtration.

- Digitalization and IoT: Integration of smart sensors and IoT devices with filtration systems allows for real-time monitoring of filter performance, predictive maintenance, and optimized change-out schedules, maximizing the efficiency of media like polypropylene.

- Global Demand for Water Treatment: With increasing water scarcity and stricter discharge regulations, the demand for efficient water filter media suppliers is escalating. Polypropylene plays a crucial role in various stages of water purification, from pre-filtration to reverse osmosis pre-treatment, offering reliable removal of suspended solids. The global water treatment chemicals and equipment market is projected to reach over $100 billion by 2027, underscoring the vital role of advanced filter media.

These trends underscore the importance of continuous innovation in filter media technology to meet the diverse and evolving demands of industrial and environmental applications. Our commitment is to remain at the forefront of these advancements, offering solutions that are both effective and aligned with future industry directions.

Technical Specifications and Performance Parameters

Understanding the technical specifications of polypropylene filter media is paramount for engineers and procurement specialists to ensure optimal system performance and cost-effectiveness. Our Laminated Composite Filter Media is designed with specific parameters to address critical industrial requirements.

Key Performance Parameters:

- Micron Rating: This specifies the smallest particle size the filter can retain. Our media offers precise micron ratings from 0.5 to 100 microns, with absolute ratings ensuring over 99.9% removal efficiency for specified particle sizes. This precision is critical for sensitive applications like pharmaceutical production or semiconductor manufacturing.

- Dirt-Holding Capacity: A measure of the total amount of contaminant a filter can hold before reaching its maximum pressure drop. Our laminated structure significantly enhances this, leading to longer filter life and reduced operational costs. Typical capacities range from 100-500 g/m² depending on structure and micron rating.

- Pressure Drop: The resistance to fluid flow across the filter media. A lower initial pressure drop indicates higher energy efficiency. Our optimized fiber arrangement and composite design minimize pressure drop while maintaining high efficiency, contributing to energy savings.

- Flow Rate: The volume of fluid that can pass through the media per unit area per unit time. High flow rates are essential for high-throughput processes, which our media supports without compromising filtration quality.

- Chemical Compatibility: Polypropylene offers excellent resistance to a wide range of acids, bases, and organic solvents (pH 1-13) at temperatures up to 80°C. This broad compatibility makes it suitable for diverse chemical processing applications.

- Thermal Stability: Effective operation up to 80°C (176°F) continuously, with intermittent tolerance to higher temperatures, making it suitable for many industrial processes.

Typical Product Specification Table (Laminated Composite Filter Media):

| Parameter | Value/Range | Test Standard |

|---|---|---|

| Material Composition | 100% High-Purity Polypropylene (PP) | ASTM D4101 |

| Micron Rating (Absolute) | 0.5 µm – 100 µm | ISO 16889 |

| Nominal Thickness | 0.5 mm – 5.0 mm | ASTM D1777 |

| Basis Weight | 50 gsm – 500 gsm | ASTM D3776 |

| Max. Operating Temperature | 80°C (176°F) continuous | Manufacturer’s Data |

| Chemical Compatibility | pH 1 – 13 | Internal Testing, ISO 2812-1 |

| Tensile Strength (MD/CD) | >250 N/5cm / >150 N/5cm | ASTM D5035 |

| Initial Pressure Drop (at specified flow) | Typically < 0.1 bar (1.45 psi) | ISO 11058 |

| Filtration Efficiency | >99.9% at absolute micron rating | ISO 16889 |

Figure 2: Close-up of polypropylene filter media demonstrating uniform fiber distribution.

Application Scenarios Across Industries

The versatility and robust properties of polypropylene filter media make it a preferred choice for a multitude of applications across diverse industrial sectors. Its ability to handle a wide range of chemicals and temperatures, combined with its excellent filtration efficiency, provides significant operational advantages.

Typical Application Areas:

- Petrochemical and Chemical Processing: Used for clarifying acids, bases, solvents, and various chemical intermediates. Its superior corrosion resistance significantly extends filter life in highly aggressive environments, leading to substantial energy saving by maintaining lower differential pressures and reducing pump load.

- Water Treatment and Municipal Supply: Essential for pre-filtration in reverse osmosis (RO) and ultrafiltration (UF) systems, removing suspended solids, sediments, and colloids to protect expensive membranes. Also widely employed in municipal water supply & drainage for primary clarification and wastewater polishing.

- Food and Beverage Industry: Critical for the purification of potable water, edible oils, wines, beers, and syrups. FDA-compliant polypropylene media ensures product safety and maintains organoleptic qualities, preventing contamination without leaching harmful substances.

- Pharmaceutical and Biotechnology: Employed in the clarification of culture media, buffer solutions, and final product polishing. The inert nature of polypropylene minimizes extractables, which is vital for maintaining product integrity and compliance with strict regulatory standards like USP Class VI.

- Electronics Manufacturing: Used in the production of ultra-pure water for semiconductor rinsing and for filtering chemical baths, ensuring the removal of even sub-micron particles that could compromise sensitive electronic components.

- Oil and Gas: Filtration of injection water, completion fluids, and produced water. The material’s resistance to hydrocarbons and brines makes it ideal for challenging upstream and downstream applications.

- Metallurgy: Employed in the filtration of cooling lubricants, pickling solutions, and wastewater from metal processing, ensuring equipment protection and environmental compliance.

In each of these scenarios, the specific advantages of polypropylene—such as its low extractables, high efficiency, and robustness—contribute to enhanced process performance, product quality, and cost savings for our clients.

Key Technical Advantages of Our Laminated Composite Filter Media

Our Laminated Composite Filter Media offers distinct technical advantages, positioning it as a superior choice compared to conventional filtration media. These benefits are derived from our advanced manufacturing processes and meticulous material selection, tailored to meet demanding B2B requirements.

- Enhanced Filtration Efficiency: The multi-layered composite structure enables a graded density design, where coarser particles are captured in outer layers and finer particles in inner layers. This progressive filtration ensures higher absolute efficiency (up to 99.9% for specified microns) and prevents premature clogging of finer layers, optimizing overall performance.

- Superior Dirt-Holding Capacity: By distributing particles across multiple layers and within the depth of the media, our polypropylene filter media significantly increases its capacity to retain contaminants. This translates directly to extended service life, reducing filter change-out frequencies by up to 50% compared to single-layer media, and consequently lowering operational expenditures.

- Lower Initial Pressure Drop: The optimized pore structure and fiber arrangement minimize resistance to fluid flow. A lower initial pressure drop means less energy consumption for pumps, resulting in tangible energy savings and reduced wear and tear on pumping equipment.

- Exceptional Chemical and Thermal Resistance: Made from 100% pure polypropylene, our media exhibits excellent chemical compatibility with most acids, bases, and solvents (pH 1-13). It also withstands continuous operating temperatures up to 80°C, ensuring reliability in aggressive industrial environments where corrosion resistance is critical.

- Reduced Fiber Migration: The robust bonding within the laminated composite structure minimizes fiber release into the filtrate, which is crucial for sensitive applications like pharmaceutical manufacturing and electronics, where contamination must be strictly avoided.

- Cost-Effectiveness and Sustainability: The extended service life and high efficiency of our media contribute to a lower total cost of ownership. Fewer filter replacements mean less material consumption and reduced waste disposal, aligning with modern sustainability goals.

Figure 3: Advanced filtration system utilizing polypropylene filter media in an industrial setting.

Vendor Comparison and Differentiation

When evaluating filter media suppliers, discerning between standard offerings and truly advanced solutions is key to long-term operational success. Our Laminated Composite Filter Media differentiates itself through superior engineering and performance guarantees.

Comparison Table: Our Laminated Composite Filter Media vs. Standard Polypropylene Filter Media

| Feature/Parameter | Our Laminated Composite Filter Media | Standard Polypropylene Filter Media |

|---|---|---|

| Structure | Multi-layered, graded density composite | Single-layer or simple melt-blown/spunbond |

| Filtration Efficiency | Absolute (Beta ratio >5000) for target micron rating (>99.9%) | Nominal (Beta ratio <200) for target micron rating (90-95%) |

| Dirt-Holding Capacity | Very High (Extended lifespan, reduced change-outs) | Moderate (Frequent change-outs) |

| Pressure Drop | Low initial and sustained pressure drop | Higher initial, rapid increase with loading |

| Fiber Migration | Minimal to none due to robust bonding | Can be significant in some applications |

| Service Life | Extended (2x-4x longer than standard) | Standard (Shorter, application-dependent) |

| Cost-Effectiveness (TCO) | High (Lower long-term operational costs) | Lower initial, higher long-term operational costs |

Our commitment extends beyond just the product. We are recognized as reliable water filter media suppliers, emphasizing consistent quality, timely delivery, and comprehensive technical support. This holistic approach ensures our clients receive not just a product, but a complete filtration solution that adds tangible value to their operations. We leverage over two decades of experience in the industry to refine our products and services continuously.

Customized Solutions and Engineering Support

Recognizing that no two industrial filtration challenges are identical, we specialize in providing tailored solutions utilizing our versatile polypropylene filter media. Our engineering team works closely with clients to understand their unique process requirements, fluid characteristics, and operational constraints.

Our customization capabilities include:

- Specific Micron Ratings: Developing media with precise absolute micron ratings to meet stringent purity requirements for diverse applications.

- Optimized Dimensions and Form Factors: Manufacturing media in various widths, lengths, and configurations (e.g., rolls, cut sheets, custom pleating) to perfectly fit existing filter housings and equipment.

- Material Blends and Treatments: Incorporating additives or surface treatments to enhance properties such as hydrophobicity, oleophobicity, antistatic behavior, or flame retardancy.

- Multi-Layered Designs: Customizing the number and composition of layers within the composite media to achieve specific filtration profiles, maximizing dirt-holding capacity and flow rate for particular contaminant types.

- Integration with Other Media: Combining polypropylene filter media with other functional layers, such as activated carbon for adsorption, or specialized materials for catalytic reactions, to create highly efficient hybrid filter solutions. This is particularly relevant for applications that would traditionally use activated filter media.

Our comprehensive engineering support includes feasibility studies, pilot testing, and ongoing performance monitoring to ensure the customized solution delivers optimal results throughout its lifespan. This collaborative approach allows us to deliver solutions that not only solve immediate filtration problems but also contribute to long-term operational efficiency and cost savings.

Real-World Application Case Studies

Our polypropylene filter media has been instrumental in solving complex filtration challenges for leading industrial clients worldwide. These case studies highlight our commitment to delivering measurable results.

Case Study 1: Enhanced Water Treatment for a Municipal Plant

Client: Major municipal water treatment plant in North America.

Challenge: The plant faced issues with inconsistent turbidity levels post-clarification, leading to premature fouling of their downstream RO membranes. Their existing sediment filters required frequent backwashing and replacement, increasing operational costs by 15% annually.

Solution: We implemented a customized Laminated Composite Filter Media solution with a graded density structure, specifically engineered for optimal removal of colloidal silica and suspended solids between 1 to 5 microns. The media was supplied in large roll formats for their automated filter press systems.

Results: Post-implementation, the plant observed a 40% reduction in RO membrane cleaning frequency and a 25% extension in filter media lifespan, directly cutting down replacement and labor costs. Turbidity levels in the treated water consistently met and exceeded regulatory standards, with a 99.8% removal efficiency for particles greater than 2 microns. The client reported significant energy savings due to less frequent backwashing cycles and lower pump head requirements.

Case Study 2: Chemical Clarification in a Petrochemical Facility

Client: A global petrochemical producer manufacturing specialty polymers.

Challenge: The client required robust filtration of highly corrosive solvent streams containing fine polymer particles, operating at elevated temperatures (70°C). Their existing filters degraded rapidly, causing product contamination and system downtime.

Solution: We provided a chemically resistant Laminated Composite Filter Media variant made from a highly stabilized polypropylene blend, configured for absolute 1-micron retention. Its inherent corrosion resistance and high thermal stability were key factors.

Results: The new media significantly improved solvent purity, reducing particulate contamination by over 99.5%. The filter lifespan increased by 300% (from 2 weeks to 6 weeks) compared to their previous solution, drastically cutting maintenance frequency and material costs. This also led to reduced disposal volumes of hazardous waste, enhancing environmental compliance and further energy saving by minimizing reprocessing.

Ensuring Trust and Reliability: Certifications and Guarantees

Our commitment to quality and customer satisfaction is underpinned by rigorous adherence to international standards and transparent operational practices. We understand that for B2B partners, trust is built on demonstrable expertise, consistent quality, and reliable performance.

- Certifications: Our manufacturing facilities are ISO 9001:2015 certified, ensuring a robust Quality Management System across all stages of production, from raw material procurement to final product inspection. Products intended for food and beverage applications comply with FDA regulations (CFR Title 21), guaranteeing safety for direct and indirect food contact.

- Authoritative References: Our testing protocols for polypropylene filter media adhere to globally recognized standards such as ISO 16889 for filtration performance, ASTM D5035 for tensile strength, and other relevant ANSI and industry-specific benchmarks. We regularly collaborate with independent third-party laboratories to validate our product claims and performance data.

- Partner Clients: We have successfully served a diverse portfolio of clients, including Fortune 500 companies in the petrochemical, pharmaceutical, and electronics sectors, establishing long-term partnerships built on mutual trust and proven product efficacy. Our longevity, with over two decades of dedicated service in the filtration industry, speaks to our sustained reliability and market leadership.

- Test Data and Chart-Based Analysis: We provide comprehensive technical data sheets, including initial pressure drop curves, dirt-holding capacity graphs, and filtration efficiency charts, derived from rigorous in-house and third-party testing. This data allows clients to make informed decisions and accurately predict product performance in their specific applications.

We stand by the quality and performance of our Laminated Composite Filter Media, offering solutions that not only meet but often exceed the stringent demands of modern industrial processes.

Frequently Asked Questions (FAQ)

- Q1: What makes polypropylene filter media suitable for corrosive environments?

- A1: Polypropylene is inherently resistant to a wide range of chemicals, including most acids, bases, and many organic solvents. This excellent chemical compatibility, across a broad pH range (1-13), prevents degradation and ensures consistent performance even in highly corrosive process streams.

- Q2: How does Laminated Composite Filter Media improve filter lifespan?

- A2: Its multi-layered, graded density structure allows for sequential particle capture. Coarser particles are retained by outer layers, preventing premature clogging of finer inner layers. This maximizes the media’s dirt-holding capacity, significantly extending its service life and reducing change-out frequency.

- Q3: Can your polypropylene filter media be customized for specific applications?

- A3: Absolutely. We offer extensive customization options, including precise micron ratings, specific dimensions, tailored material blends for enhanced properties (e.g., thermal stability, surface treatments), and optimized layered designs to meet unique flow and purity requirements.

- Q4: What are the typical lead times for your filter media products?

- A4: Standard products typically have a lead time of 2-4 weeks. For customized solutions, lead times can range from 4-8 weeks, depending on complexity and order volume. We work diligently to meet urgent client requirements and provide transparent timelines from quotation to delivery.

- Q5: What certifications do your products hold?

- A5: Our products are manufactured under ISO 9001:2015 certified quality management systems. Many of our polypropylene filter media products also comply with FDA regulations (CFR Title 21) for food and beverage contact materials, as well as relevant industry standards like ISO 16889.

Figure 4: Quality assurance testing in a modern laboratory for filter media.

Logistics, Warranty, and After-Sales Support

We are committed to providing a seamless experience from initial inquiry to post-installation support. Our logistical capabilities, warranty assurances, and dedicated customer service are designed to provide maximum confidence and minimize operational disruptions for our B2B partners.

- Lead Time & Fulfillment: We maintain a robust inventory of standard polypropylene filter media products and streamlined production lines for custom orders. Our global distribution network ensures efficient and reliable delivery, minimizing lead times and optimizing supply chain logistics for our clients worldwide.

- Warranty Commitments: All our Laminated Composite Filter Media products come with a standard 12-month limited warranty against manufacturing defects, effective from the date of shipment. This warranty underscores our confidence in the quality and durability of our products, subject to proper installation, use, and maintenance as per our guidelines.

- Customer Support & After-Sales Service: Our technical support team comprises experienced filtration engineers available to provide expert guidance, troubleshoot issues, and offer optimization advice. We offer comprehensive after-sales support, including performance analysis, replacement recommendations, and on-site assistance for complex filtration challenges. Our goal is to ensure long-term operational excellence and client satisfaction.

For further inquiries regarding lead times, specific warranty terms, or to access our technical support, please contact our sales or support team directly. We are dedicated to building enduring partnerships based on superior product performance and unparalleled service.

Conclusion

The advanced properties and versatile application range of our Laminated Composite polypropylene filter media position it as an indispensable component in modern industrial filtration. By offering superior filtration efficiency, extended service life, and robust chemical and thermal resistance, these materials provide tangible benefits in terms of operational efficiency, cost reduction, and environmental compliance. Our commitment to continuous innovation, stringent quality control, and comprehensive customer support ensures that our clients receive not just a product, but a complete, optimized filtration solution tailored to their specific needs. Partner with us to leverage cutting-edge filtration technology and achieve unparalleled process purity and performance.

References

- ISO 16889: Hydraulic fluid power – Filters – Multi-pass method for evaluating filtration performance of a filter element. International Organization for Standardization.

- ASTM D4101: Standard Specification for Polypropylene Plastic Injection and Extrusion Materials. ASTM International.

- Liu, P. (2018). Advanced filtration technologies for industrial wastewater treatment: A review. Journal of Water Process Engineering, 25, 125-138.

- Smith, J. R., & Johnson, L. K. (2020). Innovations in polymer-based filter media for enhanced chemical resistance. Polymer Engineering & Science, 60(3), 450-461.

- The Freedonia Group. (2023). World Industrial Filters Report. Industry Study.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog