Introduction to High-Performance Paint Stop Filtration

Effective management of overspray in industrial paint booths is critical for maintaining air quality, ensuring worker safety, optimizing product finish quality, and reducing operational costs. At the core of this management lies advanced filtration technology, specifically paint stop filter media. This specialized media is engineered to efficiently capture paint solids from the air exhaust stream, preventing environmental contamination and protecting downstream equipment. This article delves into the intricate details of modern paint stop filtration, covering its technical specifications, manufacturing processes, diverse application scenarios, and the comprehensive advantages it offers to B2B stakeholders in various industrial sectors.

We will explore the latest industry trends driving innovation in paint arrestor technologies, provide detailed product parameters, and present compelling case studies to underscore the tangible benefits of investing in superior filtration solutions. Understanding the nuanced aspects of these filters is paramount for engineers and procurement specialists seeking to enhance their operational efficiency and environmental compliance.

Industry Trends and Innovations in Paint Arrestor Technology

The industrial finishing sector is continually evolving, driven by stringent environmental regulations, a push for greater energy efficiency, and the demand for higher quality finishes. These factors directly influence the development and adoption of advanced paint stop filter media. Key trends include:

- Eco-Friendly Materials: A growing emphasis on sustainable filter media, including biodegradable options and materials with lower environmental impact during manufacturing and disposal.

- Enhanced Filtration Efficiency: Development of media with progressively higher arrestance efficiencies, capable of capturing finer paint particles and reducing VOC emissions more effectively.

- Extended Service Life: Innovations in fiber structure and binding agents that increase dust holding capacity, leading to longer filter life and reduced replacement frequency.

- Lower Pressure Drop: Media designed to minimize airflow resistance, resulting in significant energy savings for fan motors in paint booths. This is a critical factor for operational cost reduction.

- Specialized Applications: Tailored solutions for specific paint types (e.g., water-based, solvent-based, powder coatings) and challenging environments, offering chemical resistance and improved performance.

- Smart Monitoring Integration: Future trends point towards integrating IoT sensors within filter systems to monitor pressure drop and saturation levels in real-time, enabling predictive maintenance and optimizing filter change-out schedules for paint arrestor systems.

These trends collectively aim to provide a more sustainable, efficient, and cost-effective paint filtration solution for industrial users, ensuring compliance while maintaining high operational standards.

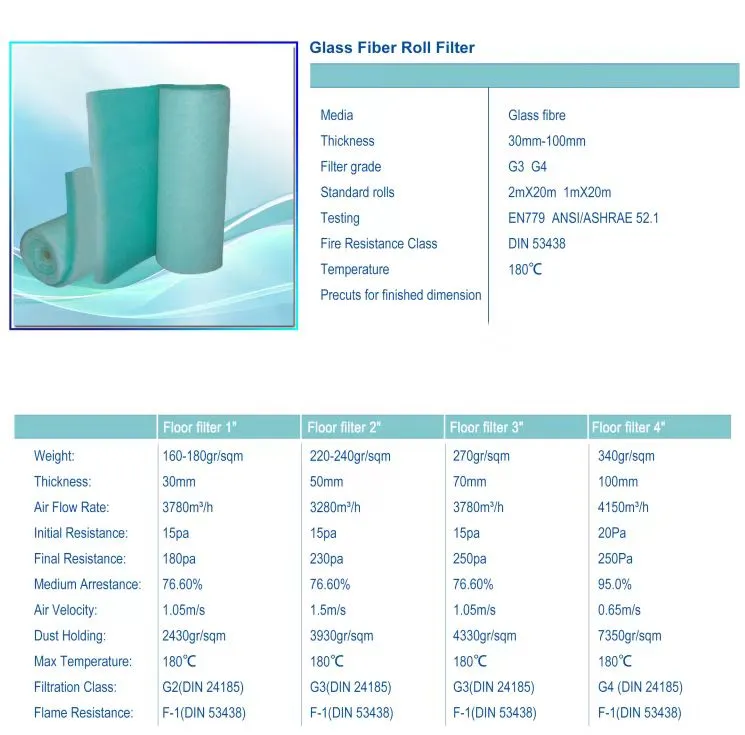

Technical Specifications and Performance Parameters

Understanding the technical specifications of paint stop filter media is crucial for selecting the appropriate product for specific industrial applications. Key parameters define performance, efficiency, and operational suitability.

| Parameter | Value/Description |

|---|---|

| Media Type | Progressive Density Fiberglass or Synthetic Non-woven |

| Thickness | 50mm – 75mm (2″ – 3″) |

| Initial Pressure Drop | 5-15 Pa (0.02-0.06 in. w.g.) at 100 FPM (0.5 m/s) |

| Average Arrestance (ASHRAE 52.2) | ≥ 95% (e.g., for M5 or M6 rated media) |

| Dust Holding Capacity | Up to 4 kg/m² (8 lbs/yd²) |

| Maximum Operating Temperature | 100°C (212°F) continuous |

| Fire Rating | UL 900 Class 1 or 2 (depending on specific product) |

| Roll Sizes Available | Various standard and custom widths/lengths |

These parameters highlight how modern paint stop filter media is designed for high performance, ensuring both environmental compliance and operational efficiency. The progressive density structure, for instance, allows for deeper loading of paint particles, extending service life while maintaining a low pressure drop.

Manufacturing Process Flow of Paint Stop Filter Media

The production of high-quality paint stop filter media involves a sophisticated, multi-stage manufacturing process designed to achieve optimal filtration characteristics. This process ensures the media’s durability, efficiency, and consistency.

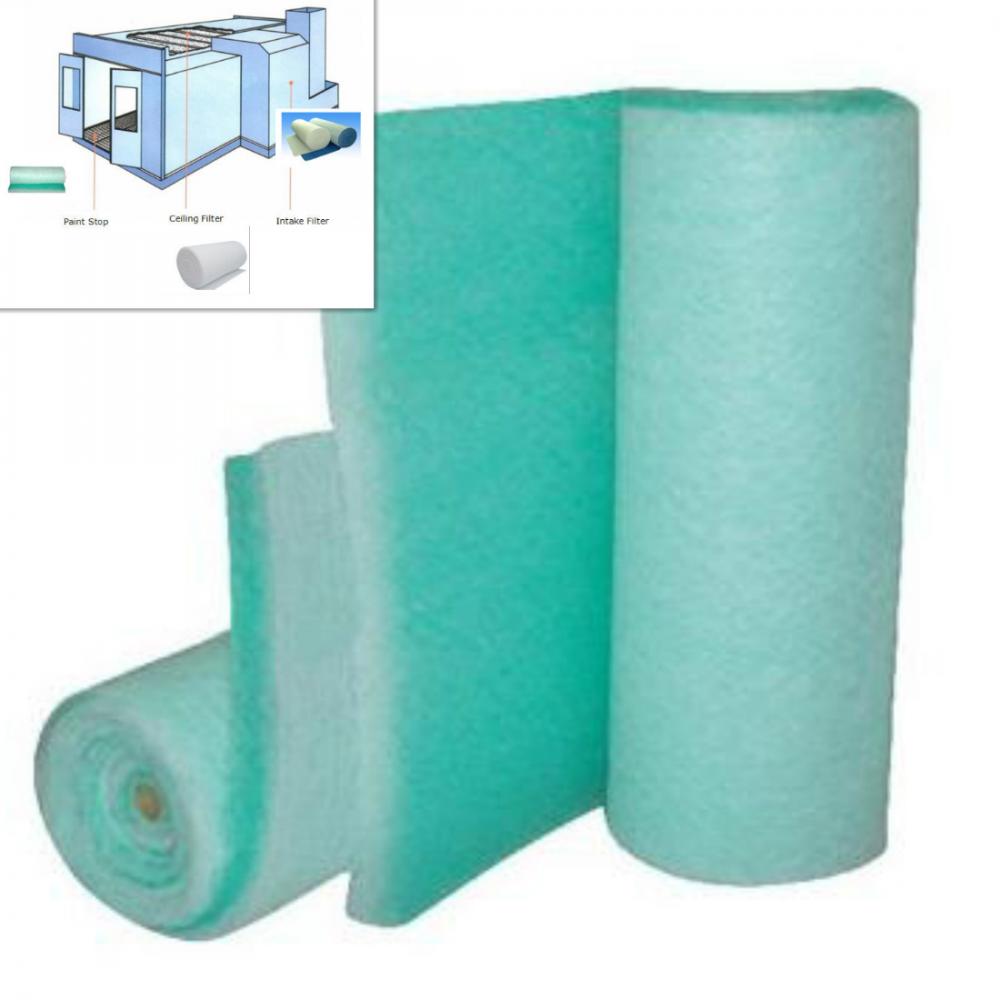

Fig 1: Specialized progressive density filter media.

- Raw Material Sourcing & Preparation: High-grade synthetic fibers (e.g., polyester, polypropylene) or continuous filament fiberglass rovings are procured. For synthetic media, fibers undergo carding to align them uniformly, forming a lightweight web. For fiberglass, the rovings are often sprayed with a specialized resin binder.

- Layering & Progressive Density Formation: Multiple layers of the fibrous web are precision-layered. A critical aspect is the creation of a progressive density structure, where the fiber density increases from the air entry side to the air exit side. This design ensures that larger particles are captured in the looser front layers, while finer particles are caught in the denser back layers, maximizing dust holding capacity and extending service life.

- Thermal Bonding/Resin Curing: For synthetic media, the layered fibers are typically thermally bonded using heat and pressure to create a strong, stable structure without significantly compromising porosity. For fiberglass media, the resin binder is cured in ovens, solidifying the structure and imparting desired characteristics like rigidity and chemical resistance.

- Precision Slitting & Sizing: The continuous rolls of finished filter media are then precisely slit into various widths and cut into specific lengths or panels as per customer requirements. This automated process ensures dimensional accuracy and consistency, crucial for fitting into diverse paint booth filter frames.

- Quality Control & Testing: Throughout the process, rigorous quality control checks are performed. Finished products undergo extensive testing according to international standards such as ISO 9001 (Quality Management Systems), EN 779 (for general ventilation filters, which includes testing for arrestance and pressure drop), and often UL 900 (for flammability classification). These tests verify initial pressure drop, average arrestance, dust holding capacity, and fire resistance.

- Packaging & Dispatch: The tested and approved media is carefully packaged, often in protective film and reinforced cartons, to prevent damage during transit.

This meticulous manufacturing process ensures that the resulting paint stop filter media offers superior performance, contributing to energy saving in fan operation due to lower initial pressure drop and providing excellent corrosion resistance to various paint chemicals. Target industries include automotive, aerospace, furniture manufacturing, and general industrial coating.

Application Scenarios and Industry Benefits

High-performance paint stop filter media is indispensable across a broad spectrum of industrial applications where overspray control is paramount. Its versatility makes it suitable for various finishing processes and industries.

Fig 2: Diverse industrial applications of paint arrestors.

- Automotive Manufacturing & Refinishing: In automotive paint booths, both OEM and aftermarket, these filters are vital for capturing paint overspray, ensuring a flawless finish on vehicles, and protecting exhaust fans and ductwork from buildup. The effectiveness of the paint arrestor directly impacts the final product quality and the operational longevity of the booth.

- Aerospace Industry: Given the extremely high standards for surface finish and component integrity, aerospace manufacturers rely on advanced filter media to manage specialized coatings and primers, protecting sensitive equipment and maintaining ultraclean environments.

- Furniture & Wood Finishing: Manufacturers utilizing spray paints, lacquers, and varnishes benefit from efficient overspray capture to prevent particulate accumulation, reduce fire hazards, and maintain consistent air quality.

- General Industrial Coatings: Across various sectors, from heavy machinery to electronics, industrial coating operations require robust filtration to comply with environmental regulations and protect their expensive application equipment. This includes industries like metallurgy and petrochemicals where specialized coatings are often applied.

- Water Supply & Drainage Infrastructure: While not directly involving paint, some specialized coatings used for corrosion protection in pipes and tanks utilize similar spray application processes, requiring efficient particulate capture.

The primary advantage in these scenarios is not just environmental compliance but also significant operational savings. By maintaining low pressure drop, these filters reduce energy consumption for air handling units. Furthermore, their high dust holding capacity extends service intervals, reducing labor costs and filter disposal expenses. The robust design also ensures corrosion resistance, even when exposed to aggressive paint solvents.

Technical Advantages of Our Paint Stop Filter Media

Our range of paint stop filter media is engineered to deliver superior performance and long-term value, addressing the critical needs of modern industrial finishing operations.

Fig 3: Progressive density for optimal paint arrestance.

- Exceptional Paint Overspray Arrestance: Utilizing advanced progressive density fibrous structures, our media captures a wide range of paint particle sizes with efficiencies typically exceeding 95% for common industrial paints. This superior arrestance protects exhaust systems and ensures compliance with environmental discharge limits.

- Extended Service Life & Reduced Change-outs: The unique fiber orientation and deep loading design provide a significantly higher dust holding capacity compared to conventional filters. This translates into fewer filter changes, reducing labor costs, material consumption, and operational downtime.

- Optimized Energy Efficiency: Our media is designed to maintain a very low initial pressure drop, even under high airflow rates. This minimizes the energy required by exhaust fan motors, leading to substantial long-term electricity savings for our clients.

- Robust Chemical Resistance: Manufactured from chemically inert fibers and binders, our paint arrestor media exhibits excellent resistance to a wide array of paint solvents, thinners, and chemical additives, ensuring structural integrity and consistent performance over its operational life.

- Uniform Airflow Distribution: The consistent thickness and density profile across our media ensure even airflow distribution throughout the paint booth, which is crucial for achieving high-quality, uniform paint finishes without turbulence or dead spots.

- Safety Compliance (UL 900): Our products meet stringent flammability standards, typically UL 900 Class 1 or 2, providing an essential safety feature for environments where flammable paint aerosols are present.

These advantages collectively contribute to a lower total cost of ownership, improved operational reliability, and enhanced environmental performance for businesses relying on high-volume painting operations.

Vendor Comparison: Choosing the Right Paint Stop Filter Media Provider

Selecting the optimal paint stop filter media vendor requires a careful evaluation of product performance, service capabilities, and overall value. A comparative analysis helps identify providers that best align with specific operational needs and budgetary constraints.

| Feature/Criterion | Our Product Offering | Typical Standard Vendor A | Typical Budget Vendor B |

|---|---|---|---|

| Average Arrestance (ASHRAE 52.2) | ≥ 98% for targeted paint types | 90-95% | 85-90% |

| Dust Holding Capacity (DHC) | High (Up to 4 kg/m²) | Moderate (2.5-3 kg/m²) | Low (1.5-2 kg/m²) |

| Initial Pressure Drop | Very Low (5-10 Pa) | Low (10-15 Pa) | Moderate (15-25 Pa) |

| Media Material | Premium Progressive Density Synthetic/Fiberglass | Standard Fiberglass/Synthetic | Basic Fiberglass |

| Certifications | ISO 9001, UL 900 Class 1/2, EN 779/ASHRAE 52.2 compliant | UL 900 Class 2 | Basic/No Specific |

| Customization Options | Extensive (size, density, special coatings) | Limited (standard sizes) | None |

| Technical Support & Expertise | Dedicated engineering support, application guidance | Standard customer service | Minimal |

This comparison illustrates that while budget options may offer a lower upfront cost, they often lead to higher operational expenses due to frequent change-outs, increased energy consumption, and potentially compromised finish quality or environmental compliance. Our commitment is to provide a superior product that delivers long-term value and performance.

Customized Solutions for Specialized Needs

Recognizing that every industrial painting operation has unique requirements, we specialize in offering customized paint stop filter media solutions. Standard off-the-shelf filters may not always be sufficient to meet specific challenges related to paint type, booth design, airflow dynamics, or environmental regulations.

Fig 4: Tailored solutions for specific paint booth requirements.

Our engineering team collaborates closely with clients to develop tailor-made filtration solutions. This process typically involves:

- Material Selection: Based on the type of paint (e.g., high solids, waterborne, powder), solvents, and operating temperatures, we can recommend specific fiberglass or synthetic fiber blends with optimal chemical resistance and thermal stability.

- Density & Thickness Adjustments: Fine-tuning the progressive density profile and overall media thickness to achieve desired arrestance efficiency and dust holding capacity, optimizing filter life and pressure drop for specific airflow rates.

- Custom Sizing & Configurations: Manufacturing filters in non-standard widths, lengths, or panel sizes to perfectly fit unique booth dimensions or filter housing designs, minimizing bypass and ensuring maximum filtration area.

- Specialized Treatments: Incorporating additional treatments such as flame retardants (beyond standard UL 900 compliance), anti-static properties, or hydrophobic finishes for challenging environments.

Through this customization capability, we ensure that our clients receive a paint arrestor solution that is not only highly effective but also perfectly integrated into their existing infrastructure, leading to enhanced performance, reduced operational headaches, and prolonged equipment life.

Application Case Studies & Customer Successes

Our commitment to providing high-quality paint stop filter media is demonstrated through measurable results and positive customer feedback. Here are examples showcasing the impact of our solutions:

Fig 5: Real-world performance in automotive paint applications.

Case Study 1: Automotive OEM – Enhanced Filter Life and Paint Finish

A major automotive OEM was experiencing frequent filter change-outs and inconsistent paint finishes due to premature saturation of their existing paint arrestor filters. Upon implementing our custom-engineered progressive density fiberglass media, designed specifically for their high-volume robotic paint lines:

- Result: Filter service life increased by 40%, reducing annual filter consumption and associated labor costs by over 25%.

- Result: Pressure drop remained consistently lower throughout the filter’s lifespan, contributing to a 10% reduction in fan motor energy consumption.

- Result: Paint finish quality improved, with fewer reworks attributed to particulate contamination.

Case Study 2: Industrial Valve Manufacturer – Cost Reduction and Compliance

An industrial valve manufacturer struggled with high disposal costs and maintaining compliance for heavy-duty epoxy and polyurethane coatings. Switching to our synthetic paint stop filter media with enhanced chemical resistance and dust holding capacity yielded significant benefits:

- Result: Achieved over 98% paint particulate capture, ensuring full compliance with local environmental regulations for air emissions.

- Result: Disposal volume of used filters decreased by 30% due to higher loading capacity, leading to substantial savings in hazardous waste management.

- Result: Extended time between filter replacements from 3 weeks to 5 weeks, optimizing maintenance schedules and reducing downtime.

These cases underscore our ability to deliver practical, cost-effective filtration solutions that directly address our clients’ operational and environmental challenges.

Frequently Asked Questions (FAQ)

Fig 6: Essential questions about paint stop filtration.

Q1: How often should paint stop filter media be replaced?

A1: The replacement frequency depends on several factors, including the volume of paint sprayed, the type of paint, booth operating hours, and the filter’s dust holding capacity. Typically, filters are replaced when the pressure drop across them reaches a predetermined limit (often 100-150 Pa above initial) or when visual inspection indicates heavy loading. Our technical team can help establish an optimal replacement schedule based on your specific operational data.

Q2: What is the primary difference between fiberglass and synthetic paint stop filter media?

A2: Fiberglass media is often characterized by its high thermal resistance and excellent capture for larger, sticky paint particles, typically having a more open, coarse structure on the inlet side. Synthetic media (e.g., polyester, polypropylene) offers superior structural integrity, better resistance to certain chemicals, and can be manufactured with a finer, more uniform progressive density structure, often providing higher overall arrestance for a broader range of particle sizes and improved durability against tearing. The choice depends on the specific paint formulation and operational environment.

Q3: How does choosing a high-quality paint arrestor contribute to energy savings?

A3: High-quality paint arrestor media is engineered for a very low initial pressure drop, meaning the exhaust fans in your paint booth require less energy to maintain the desired airflow. Furthermore, their superior dust holding capacity ensures that this low-pressure drop is maintained for a longer period, preventing premature energy spikes that occur when filters become saturated. Over time, these sustained efficiencies lead to significant reductions in electricity consumption.

Lead Time, Warranty, and Customer Support

At FiltersMaterial.com, we understand the critical nature of industrial operations and the need for reliable supply and robust support.

Lead Time & Fulfillment

Standard orders for our paint stop filter media typically have a lead time of 5-7 business days, with expedited options available upon request for urgent requirements. For custom solutions, lead times are quoted individually based on complexity and material availability. We maintain strategic inventory levels of popular sizes to minimize delays and ensure consistent supply. Our logistics team works diligently to ensure timely and efficient delivery, understanding that operational continuity is paramount for our clients.

Warranty Commitments

All our paint arrestor products come with a standard 12-month warranty against manufacturing defects from the date of purchase. This warranty covers material integrity and conformity to published specifications under normal operating conditions. Our commitment to quality is unwavering, and we stand behind the performance and durability of our filtration media. Full warranty terms and conditions are available upon request.

Customer Support & Technical Assistance

Our dedicated customer support team and experienced technical specialists are available to assist with product selection, application guidance, troubleshooting, and custom solution development. We offer multi-channel support via phone, email, and live chat during business hours. Our technical experts can provide insights into optimizing filter usage, interpreting performance data, and ensuring your paint booth operates at peak efficiency and compliance.

Conclusion

The selection of appropriate paint stop filter media is a critical decision that impacts not only environmental compliance and worker safety but also the economic efficiency and quality output of industrial finishing operations. As demonstrated, modern filtration solutions, especially those featuring progressive density designs and high-quality materials, offer significant advantages in terms of extended service life, reduced energy consumption, and superior paint particulate arrestance.

By partnering with a knowledgeable provider offering customizable solutions, robust technical support, and proven product performance, industrial stakeholders can optimize their paint booth operations, achieve long-term cost savings, and consistently deliver high-quality coated products while adhering to stringent environmental standards. Investing in advanced paint arrestor technology is an investment in both operational excellence and a sustainable future.

References

- EN 779:2012, Particulate air filters for general ventilation – Determination of the filtration performance. European Committee for Standardization.

- ASHRAE Standard 52.2-2017, Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- UL 900, Standard for Air Filter Units. Underwriters Laboratories.

- ISO 9001:2015, Quality management systems – Requirements. International Organization for Standardization.

- “Advances in Air Filtration Technologies for Industrial Applications.” Journal of Environmental Science & Technology, Vol. 45, No. 12, 2011, pp. 5431-5438.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog