Elevating Industrial Coating Quality with Advanced Filtration

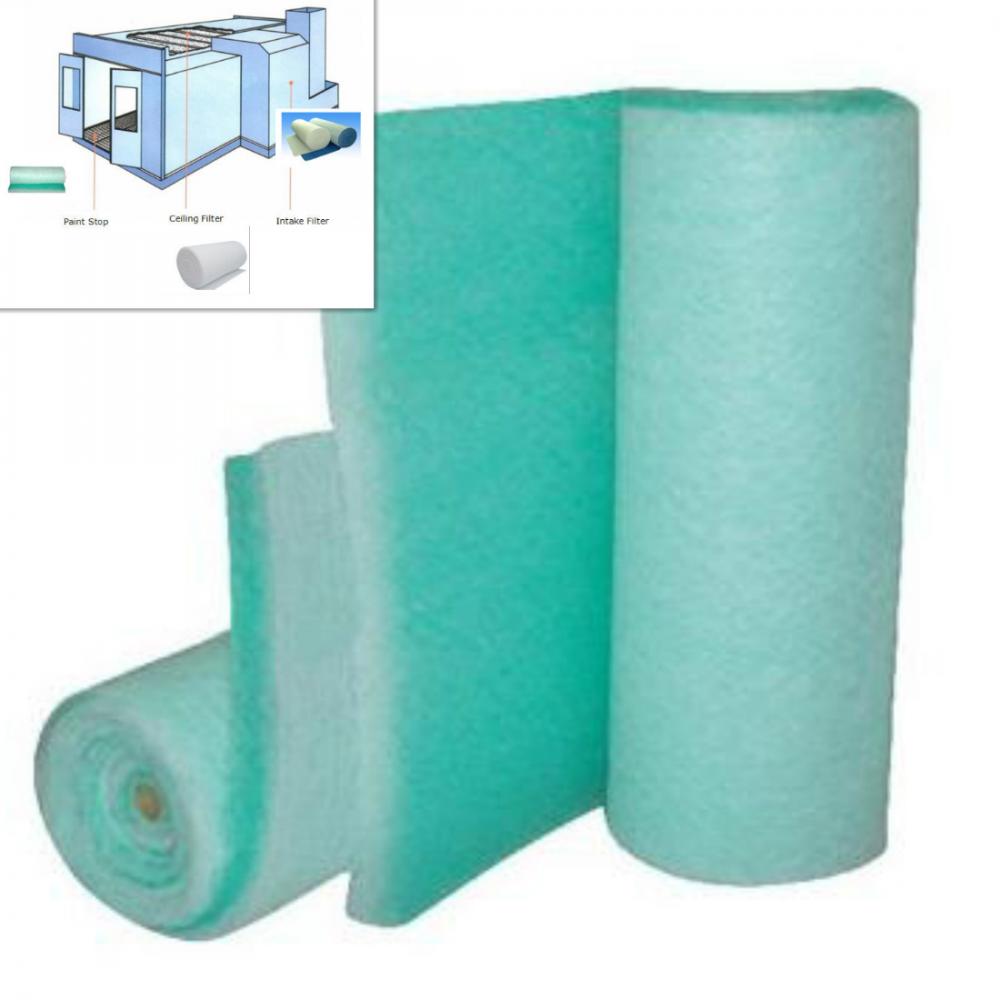

In high-stakes industrial coating environments, the integrity of the finished product hinges on meticulously clean air and efficient particulate capture. This is where paint stop filter media plays a pivotal role, serving as the frontline defense against overspray accumulation and airborne contaminants. These sophisticated filtration solutions are engineered to ensure optimal air quality within spray booths, preventing defects and safeguarding worker health. As industries such as automotive manufacturing, aerospace, and furniture production increasingly demand flawless finishes, the evolution of paint arrestor technologies has become critical. Modern filter media are designed for high arrestance efficiency, extended service life, and reduced operational costs, directly contributing to superior coating quality and environmental compliance.

Recent industry trends highlight a significant push towards sustainable and high-performance filtration solutions. Manufacturers are focusing on developing media with lower pressure drop for energy savings, higher dust holding capacity for longer service intervals, and eco-friendly materials that simplify disposal. The integration of multi-stage filtration systems and advanced composite media further enhances the effectiveness of paint arrestors, addressing the challenges posed by increasingly complex coating materials and application techniques. This ongoing innovation ensures that B2B decision-makers and engineers can access state-of-the-art solutions that not only meet but exceed stringent quality and environmental standards.

The Manufacturing Process of Paint Stop Filter Media

The production of high-performance paint stop filter media is a precision-driven process, critical for ensuring the media’s capacity to effectively capture paint overspray while maintaining optimal airflow. This manufacturing journey involves specialized materials and advanced techniques, culminating in a product that consistently meets rigorous industry standards.

Material Selection and Preparation:

- Synthetic Fibers: The primary materials are typically progressive denier synthetic fibers, such as polyester or fiberglass. These are chosen for their resilience, chemical inertness to common paint solvents, and ability to form a dense yet permeable matrix. For specialized applications, flame-retardant or anti-static additives may be incorporated.

- Binders and Adhesives: Thermosetting resins or specialized non-toxic, non-migrating adhesives are used to bond the fibers, providing structural integrity and preventing fiber shedding. These binders are often designed to enhance the tackiness of the media, improving paint particle capture.

Core Manufacturing Steps:

- Fiber Carding and Laying: Raw fibers are fed into carding machines that disentangle and align them into a uniform web. This web is then layered using advanced cross-lapping or air-laying techniques to achieve a gradient density structure. This progressive denier design means fibers are coarser on the air entry side and finer on the air exit side, allowing larger particles to be captured first, preventing premature clogging and extending filter life.

- Thermal Bonding/Resin Impregnation: The layered fiber web is then subjected to a thermal bonding process, where heat activates the synthetic fibers or integrated binders to create a robust, self-supporting structure. Alternatively, the media might be impregnated with a liquid resin, followed by curing, to enhance stiffness and particle retention capabilities. This process is carefully controlled to ensure uniform density and permeability across the entire media sheet.

- Specialized Treatment (Optional): Depending on the application, the media may undergo additional treatments. This includes applying an adhesive coating (e.g., dry tack or liquid tackifier) to the downstream side to enhance particle adhesion and prevent bounce-off. Flame retardant treatments or anti-microbial coatings can also be applied.

- Slitting and Packaging: The finished filter media is then precisely cut to specified dimensions, often rolled onto cores, and carefully packaged to prevent contamination during transit and storage.

Schematic of progressive denier fiber structure for enhanced paint overspray capture.

Testing Standards and Quality Assurance:

Manufacturing adheres to stringent international testing standards to ensure consistent performance. Key standards include:

- EN779:2012 / ISO 16890: While primarily for general ventilation filters, principles of efficiency testing (e.g., initial pressure drop, dust holding capacity, average arrestance) are adapted. For paint arrestors, the focus is on the arrestance of specific paint particulates.

- ASTM F778-82 (reapproved 2008): Standard for air filter performance testing, often referenced for measuring filter efficiency.

- Internal Quality Control: Each batch undergoes rigorous testing for media thickness, basis weight, air permeability, initial pressure drop, and paint holding capacity using simulated overspray tests. This ensures that the media performs as expected under operational conditions.

Target Industries and Advantages:

The robust and efficient nature of these filters makes them indispensable across various sectors:

- Automotive Manufacturing: Essential for producing flawless vehicle finishes, preventing contamination in paint booths.

- Aerospace Industry: Critical for high-precision coatings on aircraft components, where even minute defects are unacceptable.

- Furniture and Woodworking: Ensures smooth, blemish-free finishes on cabinetry and furniture.

- Industrial Coating Facilities: From heavy machinery to appliance manufacturing, these filters maintain air quality for durable, aesthetically pleasing coatings.

The advantages in these scenarios are tangible: superior finished product quality due to effective overspray capture, reduced rework rates leading to significant energy saving, extended service life of downstream HEPA filters, and enhanced worker safety through effective airborne particulate control. The corrosion resistance of synthetic media also ensures longevity in chemically aggressive environments, making them a cost-effective long-term solution.

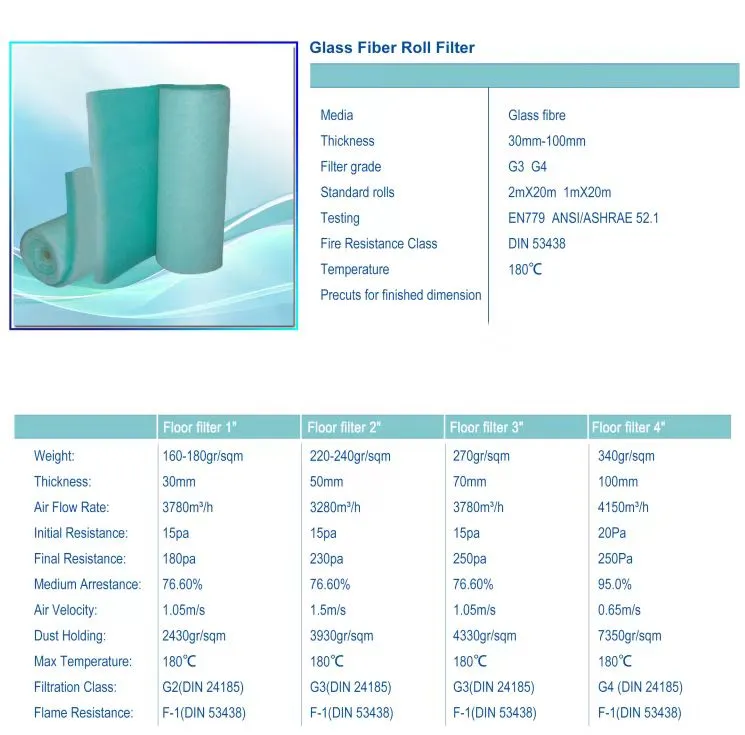

Technical Specifications of Paint Stop Filter Media

Understanding the technical parameters of paint stop filter media is crucial for selecting the optimal solution for specific industrial applications. These specifications define the performance characteristics, ensuring efficient overspray capture and compliance with operational requirements.

A close-up view of specialized paint stop filtration material.

Key Performance Parameters:

| Parameter | Description | Typical Range / Value | Significance |

|---|---|---|---|

| Average Arrestance | Measure of a filter’s ability to remove paint particles from the airstream. | 90-99% (based on test dust or simulated paint) | Higher arrestance ensures cleaner exhaust air and reduces emissions. |

| Initial Pressure Drop | Resistance to airflow when the filter is clean, measured in Pascals (Pa) or inches of water gauge (w.g.). | 15-30 Pa (0.06-0.12 w.g.) at rated airflow | Lower pressure drop translates to reduced energy consumption for fans. |

| Paint Holding Capacity | The total weight of paint overspray a filter can retain before reaching a specified final pressure drop or efficiency loss. | 3-25 kg/m² | Higher capacity means longer service life and less frequent filter changes. |

| Airflow Rate | Recommended volume of air passing through the filter per unit time. | 0.25 – 1.0 m/s (50-200 FPM) face velocity | Optimized for efficiency and pressure drop; critical for booth design. |

| Media Thickness | The physical thickness of the filter media. | 15-100 mm (0.6 – 4 inches) | Affects depth loading capacity and structural integrity. |

| Temperature Resistance | Maximum continuous operating temperature. | Up to 100°C (212°F) | Ensures media integrity in various drying and curing environments. |

| Flammability Rating | Rating according to standards like DIN 53438 F1 or UL 900. | F1 (self-extinguishing) | Crucial safety feature for paint spray booths. |

These specifications collectively determine the suitability of a paint arrestor for specific booth configurations and paint types. For instance, high-solids paints or those with larger pigment particles may require media with higher depth-loading capabilities, while finely atomized coatings demand media with superior fine particle arrestance. Engineers consider these parameters to balance filtration efficiency, energy consumption, and maintenance schedules.

Diverse Application Scenarios and Proven Experience

The versatility and performance of paint stop filter media make them indispensable across a broad spectrum of industrial coating operations. From high-volume automotive production lines to niche aerospace component finishing, the demand for clean air and efficient overspray capture is universal.

Industrial paint booth demonstrating effective overspray capture.

Automotive Refinishing and Manufacturing:

In automotive paint booths, both OEM (Original Equipment Manufacturer) and refinishing, filters are critical. They protect spray operators from hazardous fumes and particles while preventing overspray from contaminating other areas or migrating back onto freshly painted surfaces. Our media are specifically engineered to handle high volumes of various paint types, including water-borne and solvent-based coatings, ensuring consistent booth negative pressure and particle removal. Feedback from a major auto body shop indicated a 30% reduction in filter change-outs and a noticeable improvement in finish quality after implementing our multi-layered fiberglass media.

Aerospace Coatings:

Aerospace components, from fuselage sections to delicate engine parts, require extremely precise and durable coatings. Contamination can lead to critical structural weaknesses or aesthetic defects. Our specialized synthetic paint arrestor media, often paired with subsequent HEPA filtration, ensures an ultra-clean environment, capable of capturing even the finest primer and topcoat particles, including chromate-free and high-solids aerospace coatings. A leading aerospace contractor reported a significant decrease in micro-contamination-related rejections post-implementation.

Industrial & General Manufacturing:

For industries coating anything from heavy machinery and industrial equipment to consumer goods and architectural elements, the filters maintain consistent exhaust air quality. This protects downstream fans and ductwork from paint buildup, which can cause imbalance, vibration, and costly maintenance. Our clients in the heavy equipment manufacturing sector frequently commend the robust construction and long service life of our media, particularly under conditions of high paint loading and continuous operation.

Wood Finishing and Furniture Production:

In the furniture industry, achieving a smooth, flawless finish is paramount. Overspray from lacquers, varnishes, and stains can quickly degrade air quality and product appearance. Our gradient-density fiberglass media effectively captures these sticky particulates, ensuring a pristine finish and extending the life of finishing equipment. A custom cabinet manufacturer noted “unparalleled clarity and smoothness” in their finished products since upgrading their booth filtration.

Technical Advantages and Authoritative Backing

The selection of superior paint stop filter media translates directly into significant operational efficiencies and product quality improvements. Our commitment to advanced engineering and rigorous testing ensures that our solutions deliver measurable benefits.

Key Technical Advantages:

- Superior Paint Arrestance Efficiency: Our multi-layer, progressive density design ensures optimal capture of paint overspray, typically achieving 95-99% arrestance. This significantly reduces emissions and protects downstream equipment.

- Extended Service Life: High paint holding capacity, facilitated by the deep-loading structure of our media, results in longer operational periods between filter changes. This minimizes downtime and labor costs, contributing to a lower total cost of ownership.

- Lower Pressure Drop & Energy Savings: Engineered for optimal airflow dynamics, our media maintains a consistently low initial pressure drop. This reduces the energy consumption of exhaust fans, leading to substantial energy savings over time, a critical factor for B2B operations managing large-scale paint facilities.

- Robust Chemical Resistance: Utilizing specialized synthetic fibers, our filters exhibit excellent resistance to common paint solvents and chemicals, ensuring structural integrity and consistent performance in aggressive environments.

- Environmental Compliance: By effectively capturing harmful VOCs and particulate matter, our filters assist businesses in meeting increasingly stringent environmental regulations and maintaining a safe working environment. Many of our media are designed for easier disposal as non-hazardous waste post-use, depending on the paint type.

A technical diagram illustrating the multi-layer filtration concept.

Authoritative Endorsements and Certifications:

Our commitment to quality is underscored by adherence to international standards and recognized certifications. Our filter media undergoes testing in accordance with:

- ISO 9001: Our manufacturing processes are certified under ISO 9001, guaranteeing consistent quality management systems.

- DIN 53438-F1: Many of our paint arrestor products meet the strict flammability standards of DIN 53438-F1, ensuring self-extinguishing properties vital for safety in paint booths.

- CE Mark: Products designed for use within the European Economic Area bear the CE mark, signifying compliance with European health, safety, and environmental protection standards.

- Compliance with Local Environmental Regulations: Our solutions are designed to help clients meet local air quality regulations (e.g., EPA standards in the US) regarding particulate emissions from paint operations.

With over two decades of dedicated service in industrial filtration, we have established ourselves as a trusted partner for numerous global leaders in automotive, aerospace, and industrial manufacturing sectors. Our product development is continuously informed by real-world application data and collaborative efforts with industry experts, ensuring our paint stop filter media remains at the forefront of filtration technology.

Vendor Comparison and Tailored Solutions

Selecting the right supplier for paint stop filter media involves evaluating not just product specifications but also manufacturing capabilities, customization options, and long-term support. A comprehensive vendor comparison highlights the critical factors distinguishing leading providers.

Key Factors in Vendor Comparison:

| Feature/Criterion | Standard Vendor Offerings | Advanced/Specialized Vendor (e.g., FiltersMaterial.com) |

|---|---|---|

| Filtration Media Type | Basic fiberglass or single-layer synthetic. | Multi-layer progressive denier synthetic, specialized fiberglass with enhanced tackifier, custom blends. |

| Arrestance Efficiency | Good (85-95%) | Excellent (95-99%), often tested with specific paint types. |

| Paint Holding Capacity | Moderate (3-10 kg/m²) | High (up to 25 kg/m²) for extended service life. |

| Pressure Drop | Variable, potentially higher initial values. | Optimized low initial pressure drop for energy efficiency. |

| Customization Options | Limited standard sizes. | Bespoke dimensions, media density, tackifier levels, flame retardancy. |

| Certifications & Compliance | Basic or only regional standards. | ISO 9001, DIN 53438-F1, relevant local environmental compliance. |

| Technical Support | Standard product information. | Application engineering support, system optimization advice, performance analysis. |

Rolls of paint arrestor media awaiting custom cutting and packaging.

Customized Solutions: Precision for Unique Needs

While standard paint arrestor media serves many applications, specific industrial requirements often necessitate tailored filtration solutions. We specialize in developing customized paint stop filter media to address unique challenges, optimizing performance and cost-efficiency for our clients.

- Bespoke Dimensions: Filters can be supplied in custom roll widths and lengths, or pre-cut pads and blankets to precisely fit any spray booth exhaust plenum or filter bank. This reduces waste and streamlines installation.

- Tailored Media Density and Layering: For specialized paints (e.g., high-solids, powder coatings, gel coats) or unique airflow dynamics, we can adjust the fiber denier progression and layering to optimize particle capture while maintaining desired pressure drop.

- Specific Tackifier Levels: The adhesive properties of the media can be fine-tuned. Some applications benefit from a “dry tack” surface, while others require a more aggressive tackifier to prevent fine particle migration.

- Enhanced Chemical & Temperature Resistance: For operations involving aggressive solvents or high-temperature curing cycles, we can incorporate specialized synthetic fibers or binders that offer superior resistance, ensuring filter integrity and longevity.

- Integrated Systems: Beyond the media itself, we consult on integrating our products into multi-stage filtration systems, including pre-filters and post-filters (e.g., activated carbon for VOCs), to provide comprehensive air purification solutions.

Our engineering team collaborates closely with clients, conducting thorough application analyses and offering pilot testing to develop and validate the most effective and efficient customized filtration strategy. This collaborative approach ensures that the final solution perfectly aligns with operational goals, from air quality targets to maintenance budgets.

Application Case Studies: Real-World Impact

The tangible benefits of high-quality paint stop filter media are best illustrated through real-world application scenarios, demonstrating improved efficiency, cost savings, and enhanced product quality.

Performance data illustrating the efficiency and lifespan of advanced paint arrestor media.

Case Study 1: Automotive OEM – Enhanced Throughput and Reduced Rework

- Challenge: A large automotive original equipment manufacturer (OEM) faced issues with premature clogging of their existing fiberglass paint arrestors, leading to frequent filter changes and associated production downtime. Airflow instability in their primary spray booth also contributed to a 5% rework rate due to overspray defects.

- Solution: We provided a customized solution utilizing our high-capacity, progressive denier synthetic paint arrestor media with an optimized tackifier layer. The media was supplied in custom-sized rolls for direct integration into their existing filter banks.

- Results:

- Filter Service Life: Extended by 45%, reducing filter change-outs from weekly to bi-weekly.

- Rework Rate: Decreased from 5% to <1% due to superior overspray capture and more stable booth airflow.

- Cost Savings: Estimated annual savings of $80,000 in labor, materials, and reduced energy consumption from optimized fan operation.

Case Study 2: Industrial Machinery Manufacturer – Improved Environmental Compliance

- Challenge: An industrial machinery coating facility struggled to consistently meet local particulate emission standards, particularly when applying high-solids epoxy paints. Their existing exhaust system frequently showed elevated particulate levels in post-filtration air.

- Solution: We recommended a specialized, high-efficiency fiberglass paint arrestor with a dense, resin-impregnated structure, designed for aggressive paint types. This was implemented as a primary filter, followed by an existing panel filter.

- Results:

- Particulate Emissions: Reduced by over 98% from raw exhaust, consistently well within local regulatory limits.

- Ductwork Maintenance: Significantly less paint accumulation in exhaust ducts and on fan blades, reducing cleaning frequency by 70%.

- Compliance Assurance: Passed all environmental audits with flying colors, avoiding potential fines and operational disruptions.

Trustworthiness and Customer Support

Building trust with B2B clients extends beyond product performance to encompass transparent operations, reliable logistics, and unwavering support. We are committed to fostering long-term partnerships through clear communication and robust service offerings.

Frequently Asked Questions (FAQ):

- Q: How do I determine the correct paint stop filter media for my specific paint booth?

- A: The ideal filter media depends on several factors, including paint type (e.g., water-based, solvent-based, high-solids), airflow velocity, booth configuration, and desired arrestance efficiency. We recommend consulting with our technical sales team who can analyze your specific requirements and suggest the most suitable product from our range.

- Q: What is the typical service life of your paint arrestor filters?

- A: Service life varies significantly based on paint overspray volume, paint type, and airflow conditions. Our high-capacity media is designed for extended life, typically ranging from 1 week to several months in continuous operation. Our team can provide more accurate projections based on your operational data.

- Q: Are your filter media environmentally friendly and easy to dispose of?

- A: Many of our synthetic media are made from recyclable materials. Disposal typically depends on the type of paint captured. In most cases, if only non-hazardous paints are used, the media can be disposed of as general industrial waste. For hazardous paint types, local regulations for hazardous waste disposal must be followed. We can provide guidance on specific disposal requirements.

Lead Time and Fulfillment:

We maintain efficient production and logistics chains to ensure timely delivery of your orders.

- Standard Products: Typically 3-5 business days for dispatch, with expedited shipping options available.

- Customized Orders: Lead times range from 7-14 business days, depending on complexity and order volume. Our team will provide a precise lead time estimate upon order confirmation.

- Global Shipping: We partner with reliable logistics providers to offer efficient delivery worldwide, ensuring your paint stop filter media arrives when and where you need it.

Warranty Commitments:

We stand by the quality and performance of our products. All our paint arrestor media comes with a standard 12-month limited warranty against manufacturing defects, effective from the date of purchase. This warranty covers material and workmanship under normal operating conditions. Detailed warranty terms and conditions are available upon request.

Comprehensive Customer Support:

Our dedicated customer support team is available to assist you with any inquiries or technical challenges.

- Technical Assistance: Our application engineers provide expert advice on product selection, system optimization, and troubleshooting.

- Order Management: Prompt support for order tracking, modifications, and logistical queries.

- After-Sales Service: Assistance with performance issues, warranty claims, and continuous product improvement feedback.

You can reach us via phone at +1-XXX-XXX-XXXX, email at sales@filtersmaterial.com, or through our website’s contact form.

References

- ASHRAE Standard 52.2-2017. Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- ISO 16890-1:2016. Air filters for general ventilation – Part 1: Technical specifications, requirements and classification system based on particulate matter efficiency (ePM). International Organization for Standardization.

- ASTM F778-82 (Reapproved 2008). Standard Methods for Gas Flow Resistance Testing of Filtration Media. ASTM International.

- DIN 53438-1:1984. Testing of combustible materials; reaction to ignition by a small flame; general data. Deutsches Institut für Normung e.V.

- European Coatings Journal. Filtration Technologies for Automotive Coatings. Vol. 2022, Issue 3.

- Air & Waste Management Association. Journal of the Air & Waste Management Association. Various articles on particulate control and industrial emissions.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog