Introduction to Advanced Spray Booth Ceiling Filters

In high-precision industrial finishing environments, particularly within automotive, aerospace, and general industrial coating operations, the quality of the final paint finish is paramount. This quality is directly influenced by the cleanliness of the air supply within the paint booth. At the heart of maintaining this pristine environment are spray booth ceiling filters. These critical components are engineered to deliver a uniform, laminar airflow of purified air into the booth’s working area, effectively eliminating airborne contaminants that could compromise surface quality. Beyond merely removing particles, modern paint booth ceiling filters are designed to optimize airflow distribution, reduce energy consumption, and extend maintenance cycles, contributing significantly to operational efficiency and product excellence. Understanding their technical intricacies, application benefits, and customizability is essential for any professional managing high-performance coating lines.

Current Industry Trends in Paint Booth Filtration

The industrial finishing sector is continuously evolving, driven by stringent environmental regulations, increasing demands for flawless finishes, and the push for greater energy efficiency. Key trends impacting the design and adoption of spray booth ceiling filters include:

- Higher Filtration Efficiencies: A growing demand for filters that capture finer particulates (e.g., ISO ePM1, ePM2.5 grades) to meet the increasing quality standards for automotive clearcoats and aerospace finishes.

- Energy Optimization: Manufacturers are developing filters with lower initial pressure drop and slower pressure drop increases over their service life. This reduces the energy consumption of fans, leading to significant operational cost savings.

- Sustainable Materials: A shift towards filter media manufactured from recycled or sustainably sourced synthetic fibers, alongside the development of more environmentally friendly tackifier agents.

- Smart Monitoring & IoT Integration: Integration of sensors for real-time monitoring of filter pressure drop, allowing for predictive maintenance and optimized filter change-out schedules, preventing premature replacements or compromised air quality.

- Extended Service Life: Advanced media designs and material compositions are engineered to maximize dust holding capacity, thereby extending the filter’s operational life and reducing downtime for maintenance.

These trends underscore the importance of selecting advanced filtration solutions that align with both performance requirements and broader sustainability and efficiency goals.

Detailed Manufacturing Process of Spray Booth Ceiling Filters

The manufacturing of high-performance spray booth ceiling filters is a meticulously controlled process designed to ensure consistent quality, optimal performance, and durability. Unlike heavy industrial components, filter manufacturing focuses on advanced material science and precision assembly. Below is a simplified, schematic overview of the key stages:

Process Flow Diagram:

-

1. Raw Material Procurement & Preparation:

High-quality, progressive density synthetic fibers (e.g., polyester, polypropylene) are sourced. These materials are chosen for their consistent diameter, excellent dust holding capacity, and resistance to common paint solvents. Fibers undergo quality checks for tensile strength, consistency, and chemical inertness.

-

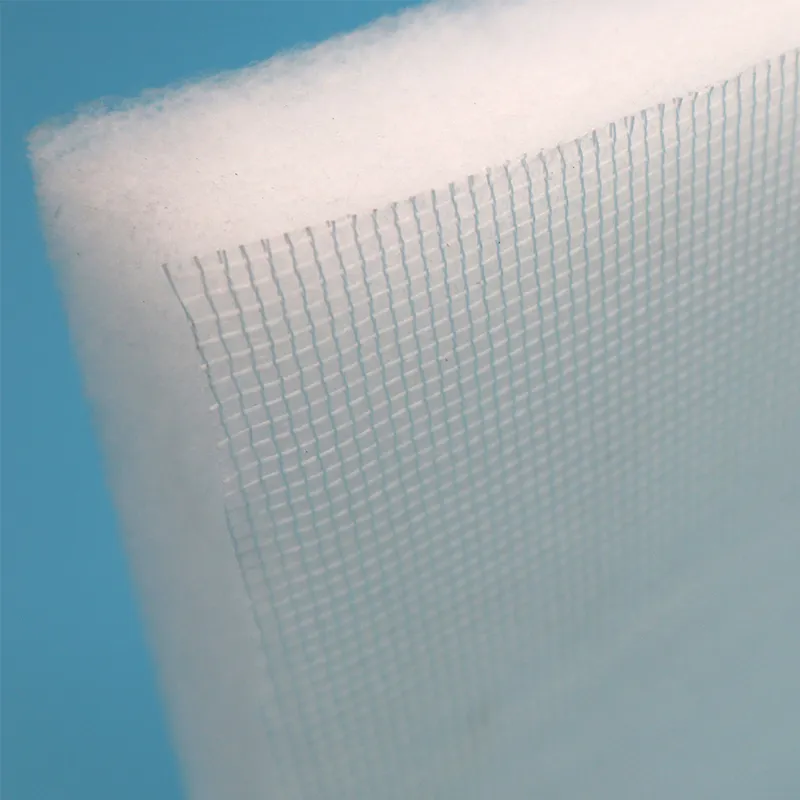

2. Fiber Web Formation (Non-Woven Technology):

Fibers are processed into a non-woven media using advanced air-lay or melt-blown techniques. This forms a deep, progressive density mat where larger particles are captured at the surface and progressively finer particles are trapped deeper within the media, maximizing dust holding capacity and minimizing pressure drop. Modern processes ensure uniform fiber distribution for consistent filtration efficiency.

-

3. Tackifier Impregnation:

The filter media is uniformly impregnated with a non-migrating, non-drying tackifier adhesive. This adhesive greatly enhances particle retention, preventing filter ‘shedding’ and ensuring that captured dust and paint overspray do not re-enter the airstream.

-

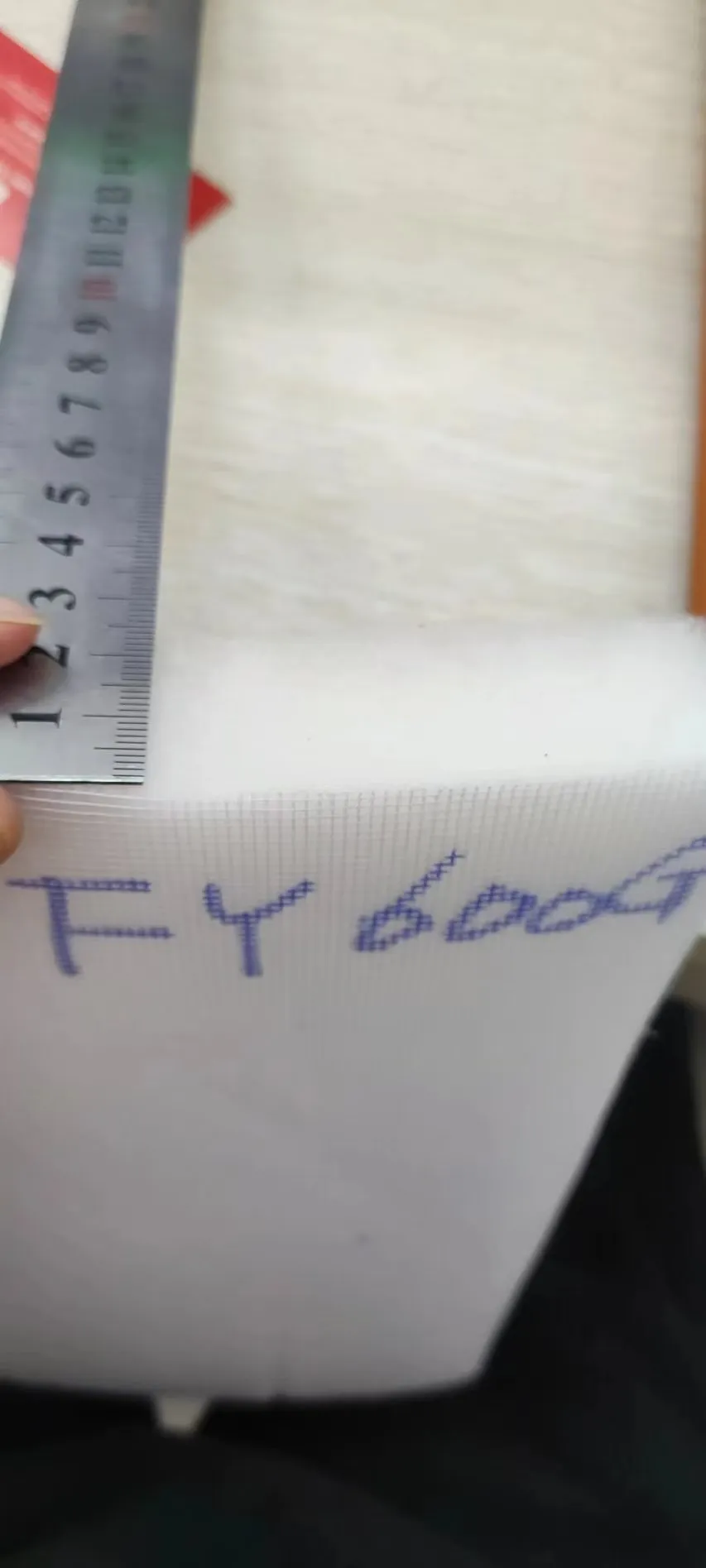

4. Scrim Backing Application (Optional/Dependent on Design):

A polyester scrim backing may be thermally bonded to the clean air side of the filter media. This scrim provides structural integrity, prevents fiber migration, and acts as a final barrier to ensure clean air delivery.

-

5. Cutting & Framing:

The filter media is precision-cut to specified dimensions. Depending on the filter type (roll media vs. panel filters), it may then be encapsulated within a robust, moisture-resistant cardboard or metal frame using specialized sealing techniques to prevent bypass leakage.

-

6. Quality Assurance & Testing:

Each batch undergoes rigorous quality control. Testing standards include ISO 16890 (for general ventilation filters, though specific paint booth standards like EN779 are more directly applicable for older classifications) and manufacturer-specific protocols for efficiency, pressure drop, dust holding capacity, and resistance to solvents and temperature. Filters are often tested for integrity and uniformity of tackifier application.

-

7. Packaging & Shipping:

Filters are carefully packaged to prevent damage and contamination during transport, ready for distribution to target industries.

Target Industries: While the term “casting, forging, CNC machining” typically applies to metal components, for filters, the analogous processes are fiber extrusion, web formation, and precision cutting/assembly. The primary target industries for these filters are automotive manufacturing and refinishing, aerospace, industrial coating, furniture finishing, and electronics assembly where surface finish is critical. The typical service life of a paint booth ceiling filter varies significantly based on booth usage, paint type, and initial contamination levels, but generally ranges from 150 to 500 operating hours. Advantages in these scenarios include superior paint finish quality, extended booth operational periods, and compliance with air quality regulations.

Technical Specifications and Performance Parameters

Selecting the appropriate spray booth ceiling filter requires a deep understanding of its technical specifications. These parameters dictate the filter’s effectiveness, operational efficiency, and longevity. Our advanced filtration media is designed to meet or exceed industry standards, ensuring optimal performance for critical finishing applications. Below is a representative table of key specifications:

Typical Product Specification Table: Spray Booth Ceiling Filter

Critical Application Scenarios and Target Industries

The precise air purification provided by paint booth ceiling filters is indispensable across a range of industries where surface finish integrity is paramount. These filters ensure that the air entering the spray booth is free from dust, lint, and other particulate matter that could cause defects in coatings. Key application scenarios and target industries include:

- Automotive Manufacturing & Refinishing: Essential for achieving Class A finishes on vehicle bodies, ensuring flawless application of primers, basecoats, and clearcoats. In collision repair shops, they prevent paint defects, reducing rework and improving customer satisfaction.

- Aerospace Industry: Critical for coating aircraft components, where even microscopic imperfections can compromise structural integrity or aerodynamic performance. Stringent cleanliness standards demand the highest efficiency filters.

- Industrial Coating & Finishing: Used in manufacturing facilities for applying protective and decorative coatings to various industrial products, machinery, and equipment, ensuring durability and aesthetic appeal.

- Furniture Finishing: For high-end furniture, a smooth and dust-free finish is a key differentiator. Ceiling filters prevent airborne particles from settling on wet lacquer or paint.

- Plastics & Electronics Finishing: Applications where precision coating is applied to plastic components or electronic enclosures, demanding a contaminant-free environment to prevent functional and aesthetic defects.

In these scenarios, the filters contribute to:

- Enhanced Product Quality: Eliminating surface defects like fisheyes, craters, and dirt inclusions.

- Reduced Rework: Minimizing the need for sanding, polishing, and repainting, saving time and materials.

- Increased Throughput: Reliable filter performance means less downtime for cleaning and defect correction.

- Compliance: Meeting stringent industry standards for paint finish quality and environmental control.

Technical Advantages of Advanced Spray Booth Ceiling Filters

Modern spray booth ceiling filters offer a range of technical advantages that go beyond basic air filtration, directly impacting operational efficiency, finish quality, and cost-effectiveness. These advantages stem from continuous advancements in material science and filter design:

- Progressive Density Media: The filter media is constructed with a gradient of fiber density, starting coarser on the air-entering side and becoming progressively finer towards the air-leaving side. This design ensures optimal capture of particles throughout the filter’s depth, maximizing dust holding capacity and extending service life while maintaining a low initial pressure drop.

- High Particle Arrestance & Efficiency: Engineered to capture a broad spectrum of airborne particles, from coarse dust to fine paint overspray, ensuring the supply air is free of defects. Efficiencies often exceed F5 (EN779) or M5 (ISO 16890) classifications, crucial for high-gloss finishes.

- Integrated Tackifier Layer: A non-migrating, non-drying tackifier adhesive is uniformly applied within the filter media. This sticky layer physically traps particles upon contact, preventing them from dislodging and migrating downstream, even under fluctuating airflow conditions. This is a critical feature for preventing fiber shedding and ensuring consistent air quality.

- Optimized Airflow Distribution: Designed to provide laminar airflow, ensuring an even, controlled curtain of clean air descends through the booth. This prevents turbulence, which can stir up settled dust, and creates a consistent environment for paint application.

- Thermal Stability & Chemical Resistance: Constructed from synthetic fibers that resist degradation from typical paint booth temperatures (including bake cycles) and are inert to common solvents and paint chemicals, ensuring structural integrity and consistent performance over time.

- Fire Safety Compliance: Many advanced filters meet fire safety standards like DIN 53438 F1, signifying they are self-extinguishing and will not contribute to the spread of fire, an important safety consideration in paint booths.

- Ease of Installation & Maintenance: Available in precise cut-to-size panels or rolls, allowing for quick and hassle-free installation and replacement, minimizing booth downtime.

Vendor Comparison: Evaluating Spray Booth Ceiling Filter Solutions

When selecting paint booth ceiling filters, a thorough vendor comparison is crucial. While many suppliers offer filters, their product quality, technical support, and value proposition can vary significantly. This comparison focuses on key parameters that B2B decision-makers should consider.

Comparison Table: Spray Booth Ceiling Filter Categories

While standard filters might offer a lower initial price point, premium filters, like those we provide, demonstrate superior performance over their lifespan, translating into significant long-term savings through reduced energy consumption, extended filter change-out intervals, and drastically improved paint finish quality, which minimizes expensive rework.

Customized Filtration Solutions for Unique Requirements

Recognizing that no two paint booths are identical, we offer customized solutions for spray booth ceiling filters to precisely match specific operational demands. Our engineering team collaborates with clients to understand their unique challenges, ensuring optimal filtration performance.

- Dimension & Configuration: Filters can be custom-cut to any required length and width, ensuring a perfect fit for diverse ceiling grid systems and booth designs. This minimizes gaps and prevents air bypass.

- Media Grade Optimization: Depending on the required finish quality (e.g., aerospace vs. general industrial), we can recommend or supply media with varying filtration efficiencies (e.g., higher ISO ePM1 or ePM2.5 for ultra-fine particle removal).

- Specialized Tackifier Formulations: For specific paint types or environmental conditions, custom tackifier agents can be incorporated to enhance adhesion properties or resistance to certain solvents.

- Flame Retardancy & Chemical Resistance: Filters can be engineered with enhanced flame retardant properties (e.g., to meet stricter local fire codes) or with media materials specifically chosen for superior chemical resistance in highly aggressive environments.

- Frame Materials: While standard filters often use cardboard frames, customized solutions can include metal frames for increased rigidity and durability in demanding conditions.

Our expertise in filtration engineering allows us to develop tailored solutions that optimize performance, reduce operating costs, and ensure compliance with the most demanding industry standards.

Application Case Studies: Realizing Tangible Benefits

Our commitment to providing superior paint booth ceiling filters is demonstrated through the measurable improvements experienced by our clients. These case studies highlight the real-world impact of advanced filtration solutions.

Case Study 1: Automotive OEM Assembly Plant

Challenge: A major automotive original equipment manufacturer (OEM) was experiencing a 7% defect rate in their final clearcoat application, attributed primarily to airborne particulates despite using standard F5 filters. This resulted in significant rework costs and production delays.

Solution: We implemented a tailored solution featuring our premium F5 equivalent (ISO ePM10 60%) ceiling filters with enhanced tackifier and scrim backing. These filters offered a lower initial pressure drop and significantly higher dust holding capacity.

Results: Within three months, the clearcoat defect rate dropped to below 2%, a 70% reduction. This translated to an estimated annual saving of over $500,000 in rework costs and a 15% increase in throughput. Filter change-out intervals were extended by 25%, further reducing maintenance costs and downtime.

Case Study 2: Industrial Machinery Coating Facility

Challenge: A manufacturer of heavy industrial machinery faced high energy costs due to frequent filter changes and high fan loads in their paint booths. Their existing filters quickly clogged, leading to increased pressure drop and inconsistent airflow.

Solution: We provided F5 filters optimized for high dust loading, featuring a deeper, progressive density media design. We also provided ongoing technical support to optimize their booth’s air balance.

Results: The facility experienced a 30% reduction in average pressure drop, leading to an estimated 10% saving in fan energy consumption. Filter service life increased by 40%, reducing annual filter procurement by 28% and minimizing labor associated with replacements. Overall finish quality also saw a noticeable improvement, particularly in gloss consistency.

Ensuring Trust: Certifications, Quality Assurance, and Expertise

Our commitment to quality and customer trust is underpinned by rigorous adherence to international standards and a steadfast dedication to excellence. We understand that for B2B decision-makers, reliability and verifiable performance are non-negotiable.

- Industry Certifications: Our spray booth ceiling filters are manufactured in facilities that adhere to ISO 9001:2015 quality management systems. Our products are tested in accordance with international standards such as EN779:2012 and increasingly ISO 16890, providing verifiable data on filtration efficiency and pressure drop. Fire classification often meets DIN 53438 F1.

- Rigorous Testing: Each batch of filter media undergoes internal and third-party testing to confirm compliance with stated specifications, including average arrestance, average efficiency, initial pressure drop, dust holding capacity, and tackifier consistency.

- Experienced Team: With over 15 years of experience in industrial air filtration, our team comprises application engineers and technical specialists dedicated to understanding and solving complex filtration challenges. We have partnered with leading manufacturers across various industries, including major automotive suppliers and aerospace maintenance facilities.

- Authoritative References: Our product development is informed by the latest research and best practices published by authoritative bodies in air quality and filtration technology. We reference standard test methods from organizations like ASHRAE and EUROVENT to ensure our performance claims are scientifically sound.

Frequently Asked Questions (FAQ)

Q: How often should spray booth ceiling filters be replaced?

A: The replacement frequency depends on several factors: the amount of overspray, type of paint used, booth operating hours, and the initial contamination level of the incoming air. Generally, they should be replaced every 150-500 operating hours, or when the pressure differential across the filter reaches its recommended final pressure drop (e.g., 250-450 Pa), to maintain optimal airflow and finish quality.

Q: What is the benefit of a tackified filter?

A: Tackifier agents are crucial for preventing captured particles, especially fine paint overspray, from becoming dislodged and re-entering the airstream (shedding). This ensures a consistently clean air supply, significantly reducing defects in the final paint finish and prolonging the life of downstream filters.

Q: Can your filters be customized for specific booth dimensions?

A: Yes, we offer comprehensive customization options. Our filters can be supplied in specific roll widths and lengths, or as pre-cut panels, to perfectly match the dimensions of your paint booth ceiling grid system, ensuring a snug fit and preventing air bypass.

Q: What environmental regulations do your filters help meet?

A: While ceiling filters are primarily for incoming air quality, their high efficiency in capturing particulates indirectly supports compliance with local air quality regulations by minimizing the release of airborne contaminants during paint application, especially when combined with efficient exhaust filtration. More directly, they ensure the finished product meets quality standards which can be part of broader industry certifications.

Logistics and Support: Lead Time, Warranty, and After-Sales Service

We understand the critical nature of continuous operations in B2B environments. Our logistics and support infrastructure is designed to provide seamless service, ensuring you have the right spray booth ceiling filters when and where you need them.

- Lead Time & Fulfillment: Standard filter sizes and popular media types typically have a lead time of 3-5 business days for dispatch. Custom orders, depending on complexity and volume, generally range from 7-15 business days. We maintain robust inventory levels to support urgent requirements and large-scale projects.

- Warranty Commitments: All our paint booth ceiling filters come with a 12-month limited warranty against manufacturing defects and material failures under normal operating conditions. This commitment reflects our confidence in the quality and durability of our products. Detailed warranty terms are available upon request.

- Customer Support & After-Sales Service: Our dedicated customer support team is available Monday to Friday, 9:00 AM – 5:00 PM (local time), via phone and email. We provide technical assistance for product selection, installation guidance, and troubleshooting. On-site technical visits can be arranged for complex system optimizations or performance diagnostics.

Our goal is to be a trusted partner, not just a supplier, providing comprehensive support throughout the lifecycle of our filtration solutions.

Conclusion

In the competitive landscape of industrial finishing, the unwavering quality of the final product is a non-negotiable differentiator. Advanced spray booth ceiling filters are more than just consumables; they are integral engineering components that directly impact finish quality, operational efficiency, and long-term cost savings. By understanding their manufacturing precision, technical specifications, diverse applications, and the benefits of premium-grade solutions, B2B decision-makers can make informed choices that elevate their entire finishing process. Partnering with a specialist vendor who emphasizes quality, offers customized solutions, and provides robust after-sales support ensures not only compliance with stringent standards but also sustained excellence in paint application.

References

- ISO 16890:2016 – Air filters for general ventilation – Part 1: Technical specifications, requirements and classification system based upon particulate matter (PM). International Organization for Standardization.

- EN 779:2012 – Particulate air filters for general ventilation – Determination of the filtration performance. European Committee for Standardization.

- ASHRAE Handbook – HVAC Systems and Equipment, Chapter 29: Air Cleaners for Particulate Contaminants. American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- DIN 53438-3:2004-01 – Testing of combustible materials; response to ignition by a small flame; surface ignition. Deutsches Institut für Normung.

- Paint Booth Maintenance & Filter Selection Guide. Various industry publications and manufacturers’ whitepapers, 2020-2023.

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog