Keywords: synthetic filter media, synthetic air filter media, synthetic air filter media rolls, synthetic filter roll

1. What is synthetic filter media?

Synthetic filter media refers to filter materials engineered from man-made fibers such as meltblown polypropylene, polyester, and synthetic composites. These materials are commonly used in air filtration systems because of their uniform fiber structure, excellent chemical resistance, high dust holding capacity, and long service life.

Types include synthetic air filter media, synthetic air filter media rolls, and synthetic filter roll, each designed for specific HVAC and industrial filtration needs.

2. Industry Trends: Synthetic Filter Media Market Insights [2023-2028]

- Global synthetic filter media market is projected to reach $6.1 billion by 2028, growing at a CAGR of 7.5% (Source: MarketsandMarkets).

- Automated production lines and advanced materials (e.g., multi-layer meltblown composites) increase product consistency and efficiency.

- Compliance with ISO 16890, EN 779, ASHRAE 52.2 standards becomes baseline for competitive entry.

- Rising demand in HVAC, clean room, automotive, metallurgy, petrochemical, food processing sectors.

3. Synthetic Filter Media Technical Parameters Comparison

| Parameter | Synthetic Pocket Filter Media | Fiberglass Media | Cellulose Media |

|---|---|---|---|

| Primary Material | 100% Polypropylene / Polyester | Borosilicate Glass | Natural Cellulose Fibers |

| Efficiency Grades | M5, M6, F7, F8, F9 (ISO ePM1 50%-90%) | M6 – F9 | G2 – G4 (Low) |

| Typical Thickness | 4mm ~ 25mm | 3mm ~ 22mm | 5mm ~ 15mm |

| Initial Pressure Drop (Pa) | 35–70 Pa (@0.25m/s) | 40–90 Pa | 45–80 Pa |

| Dust Holding Capacity (g/m²) | 370–600 | 250–420 | 90–180 |

| Moisture Resistance | Excellent (Hydrophobic) | Poor | Very Poor |

| Fire Resistance | Meets DIN 53438 F1, UL 900 | Meets DIN 53438, UL 900 | Poor |

| Service Life | 1–3 years | 6–18 months | <12 months |

| Operating Temp. | Up to 80°C | Up to 65°C | Up to 50°C |

| Standard Compliance | ISO 16890, EN 779:2012 | EN 779 | G2/G3 |

4. Synthetic Filter Media Manufacturing Process

➜

Meltblown / Spunbond Extrusion

➜

Web Formation

➜

Thermal/Ultrasonic Bonding

➜

Finishing (Calendering / Plasma Treament)

➜

Roll Slitting & Inspection

➜

Packaging & Shipping

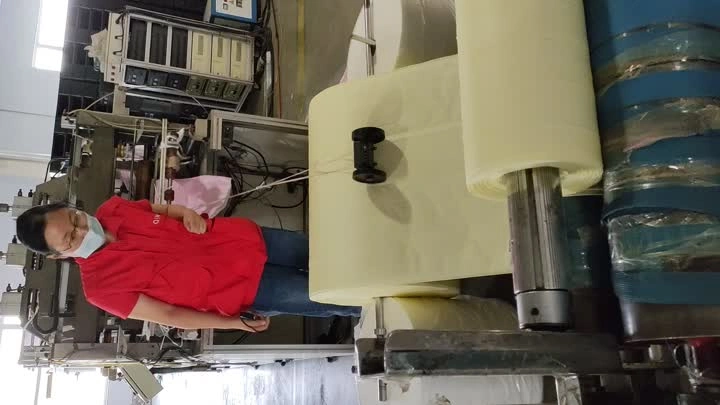

- Meltblown/Spunbond: Produces ultrafine fibers (≤2μm), maximizing surface area and filtration efficiency.

- Bonding: Ultrasonic fusion ensures consistency and eliminates fiber shedding, crucial for HVAC and clean room use.

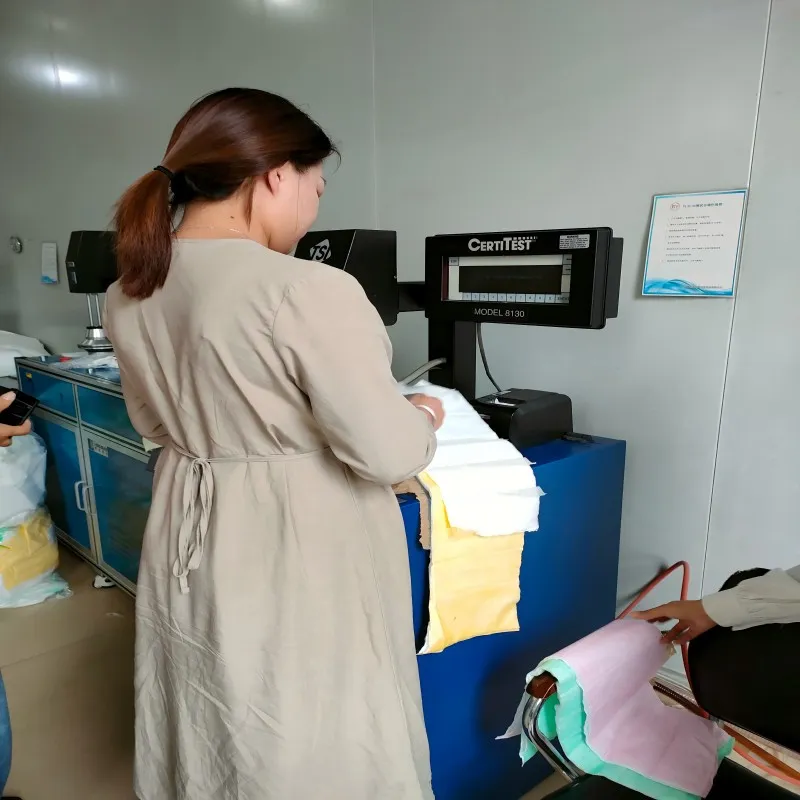

- ISO 16890 Testing: Encompasses particulate removal rates (PM2.5, PM10), pressure drop, and dust capacity.

- Customization: Thickness, roll width, efficiency, fire retardancy adapted per client/industry need.

Synthetic Filter Media Production Line

5. Synthetic Filter Media vs. Other Media: Visualization

| Media Type | Synthetic | Fiberglass | Cellulose |

|---|---|---|---|

| Dust Holding | 600 | 420 | 180 |

6. Product Spotlight: Synthetic Pocket Filter Media

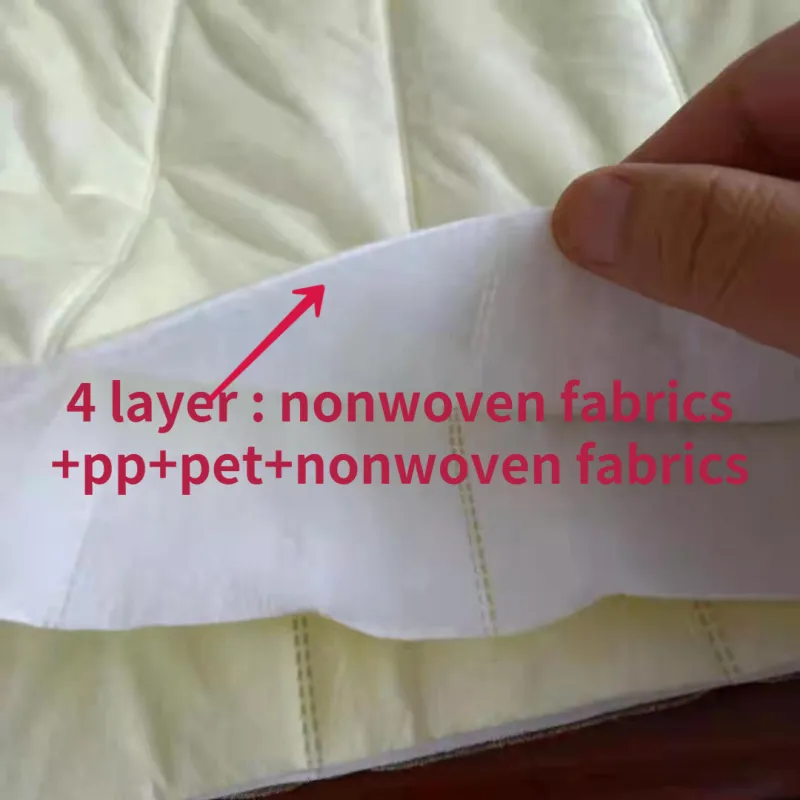

- Material: Meltblown polypropylene fibers + polyester composites

- Structure: Multi-layered (pre-filter + fine filtration)

- Grades: M5/F5, M6/F6, F7, F8, F9 (ISO ePM10, ePM2.5, ePM1 up to 90%)

- Width: 500–650mm (customizable); Roll length: 10m–100m

- Thickness: 4–25mm

- Airflow: 2500–4500 m³/h/m²

- Fire Retardancy: EN 779, DIN 53438-3 F1, UL 900

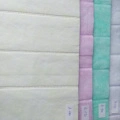

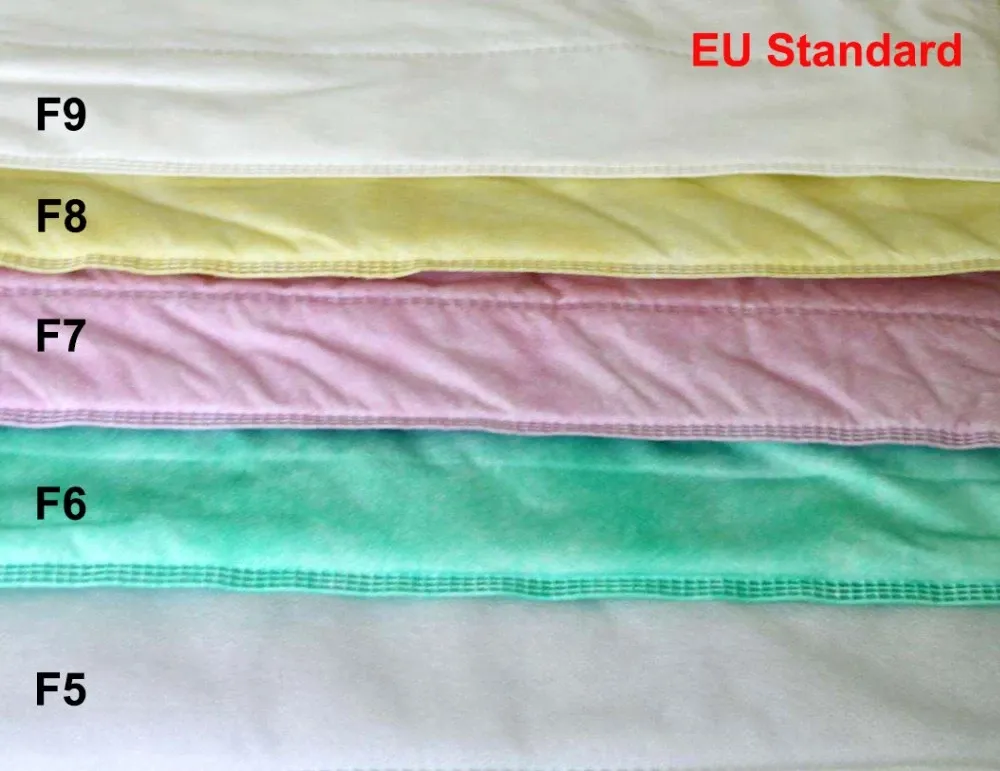

- Color: White, yellow, green, pink, blue (grade-coded)

- Usage: HVAC, spray booths, hospitals, food plants, industrial ventilation

- Certifications: ISO 16890, RoHS, SGS, FDA Contact Available

- Lifespan: Up to 3 years (varies by application)

7. Product Specification Table: Synthetic Pocket Filter Media

| Grade | Color | Thickness (mm) | Efficiency (EN 779) | Efficiency ISO16890 | Initial Pressure Drop (Pa) | Dust Holding (g/m²) |

|---|---|---|---|---|---|---|

| M5 / F5 | Green | 5–7 | 40–60% | ePM10 50–65% | 37 | 350 |

| M6 / F6 | Pink | 7–9 | 65–80% | ePM2.5 70% | 42 | 410 |

| F7 | Yellow | 8–10 | 80–90% | ePM1 75–80% | 48 | 510 |

| F8 | Blue | 10–12 | 90–95% | ePM1 85% | 52 | 580 |

| F9 | White | 12–15 | > 95% | ePM1 90% | 56 | 600 |

8. Technical Advantages: Why Choose synthetic filter media?

- High mechanical strength and tear resistance enable robust handling and prolonged filter replacement intervals.

- Thermal bonded layers ensure no fiber shedding, suitable for sensitive cleanroom/lab/HVAC uses.

- Hydrophobic fibers (water repellent) resist humidity-related clogging or biological growth.

- Lower initial pressure drop for better energy efficiency (notably in ISO tests).

- Stable performance across a wide temperature and chemical spectrum—ideal for petrochemical, metallurgy, food industries.

- Compliant with ISO 16890, EN 779:2012, UL 900 for fire safety, and FDA for food-contact filters.

- Customizable in efficiency, roll size, thickness, and color coding for warehouse management.

9. Application Scenarios

- HVAC Systems: Offices, shopping malls, hospitals, airports

Benefit: High dust holding, energy saving, fewer change-outs - Industrial Ventilation: Paint spray booths, power plants, cleanrooms

Benefit: Fiber shedding resistance, fire retardancy - Petrochemical/Refining: Chemical resistance, anti-corrosion, stable under process extremes

- Metallurgy/Steel Plants: Handles abrasive dust, high load, extended service life

- Food & Pharma Manufacturing: Fibers tested for non-toxicity, pass FDA/SGS

- Water Treatment: Prefiltration for sensitive RO/UF systems

10. Manufacturer Comparison Table

| Manufacturer | Country | Core Brand/Certifications | Main Product Types | Lead Time | Industry Focus |

|---|---|---|---|---|---|

| Filtersmaterial.com | China | ISO 16890, EN779, SGS, FDA, RoHS | Synthetic filter media, pocket filter rolls, HEPA support media | 7–18 days | HVAC, Industrial, Automotive |

| AAF Flanders | USA | UL 900, ISO 9001 | Glass/synthetic air filter rolls, high-efficiency bags | 14–28 days | Industrial, Cleanrooms |

| Freudenberg Filtration | Germany | EN 779, ISO 16890 | Polyester/premium synthetic media | 10–22 days | Automotive, HVAC, Pharma |

| Camat | Italy | ISO 16890, CE | Pre-filter & pocket filter rolls | 12–30 days | HVAC, Industry |

11. Customization & Turnkey Solutions

- Width, length, grade, color can be adjusted per customer specification.

- OEM/ODM support: Private label, custom printing, special packaging.

- Custom lamination (e.g., carbon impregnation for odor control).

- Support for roll stocks and cut-to-size delivery (synthetic air filter media rolls as per project needs).

- Integration with frame or cage (aluminum, galvanized steel) for finished filter elements.

- Supply chain tracking: Barcode, batch control for traceability (ISO 9001/SGS systems).

12. Real Application Cases & Customer Feedback

- Case 1: Dubai International Airport

Solution: Upgraded all air handling units using F7/F9 synthetic pocket filter media.

Result: Energy savings of 11.5%/year and filter change interval increase from 6 to 20 months. - Case 2: Pfizer Biologics Facility

Solution: Switched to multi-layer synthetic filter roll for LAF clean rooms.

Result: Eliminated contamination events associated with fiber shedding. - Case 3: Indian Steel Manufacturing Plant

Solution: F8 synthetic air filter media replaced fiberglass, resisting abrasive pollutants.

Result: Reduced unplanned downtime by 51% after installation.

- “Filter life extended 3x compared to previous media. Lower maintenance cost.” — HVAC Integrator, Sweden

- “No more filter collapse in high-humidity months. Reliable roll width consistency.” — Cleanroom Equipment OEM, Malaysia

13. Professional FAQ (synthetic filter media)

14. Delivery Cycle, Guarantee & Support

- Delivery cycle: Standard grades/rolls: 7–15 working days; custom specs: 15–21 days (air/sea shipping options, global supply)

- Quality assurance: Every shipment undergoes multi-point physical, efficiency, and fire testing per ISO 16890 and EN 779 protocols, documented with traceable batch numbers.

- Warranty: 24 months product defect guarantee, professional after-sales support within 24 hours.

- Technical support: Free pre-sales consulting, application engineering, on-site fitment guidance, OEM/ODM private customization, remote training for end-users.

- Sample request: Contact us for free samples (up to 3m) chemical/physical test reports included.

Get Your Synthetic Filter Media Solution →

15. References & Industry Resources

Key Standards:

- ISO 16890: Air filter particle efficiency classification

- EN 779:2012: Particulate air filters for general ventilation

Hebei Fangyu Filter Material Technology Co.,Ltd is the leading innovative developer and manufacturer all kinds of filter materials in China.pocket filter media factory Located in the economically developed Handan Hebei specialized in various kinds of filter materials from Synthetic Media,Paint stop Filter Media Pre- filter Non Woven Fabric ,Wire Mesh Backed Laminated Filter Media,Ceiling filter Auto Cabin Filter Media, polypropylene filter media, Glass Microfiber Filter Media Nonwoven Fabric,Pre- filter non woven fabric, activated carbon filter materials, EN779 bag filter materials, HEPA filter media, air filter HEPA filter media and Filter Accessories.Our filter materials have passed ISO9001:2000 quality certification since 2005.Certified by ISO9001, UL2 and SGS, with emphasis on quality and service. Our strength is the ability to find innovative ways to meet marketplace or product requirements.activated filter media price|super blog